- Stock: In Stock

- Model: SCJ005646

- SKU: SCJ005646

Available Options

Ask a Question About This Product

- Specifications

| attribute-list | |

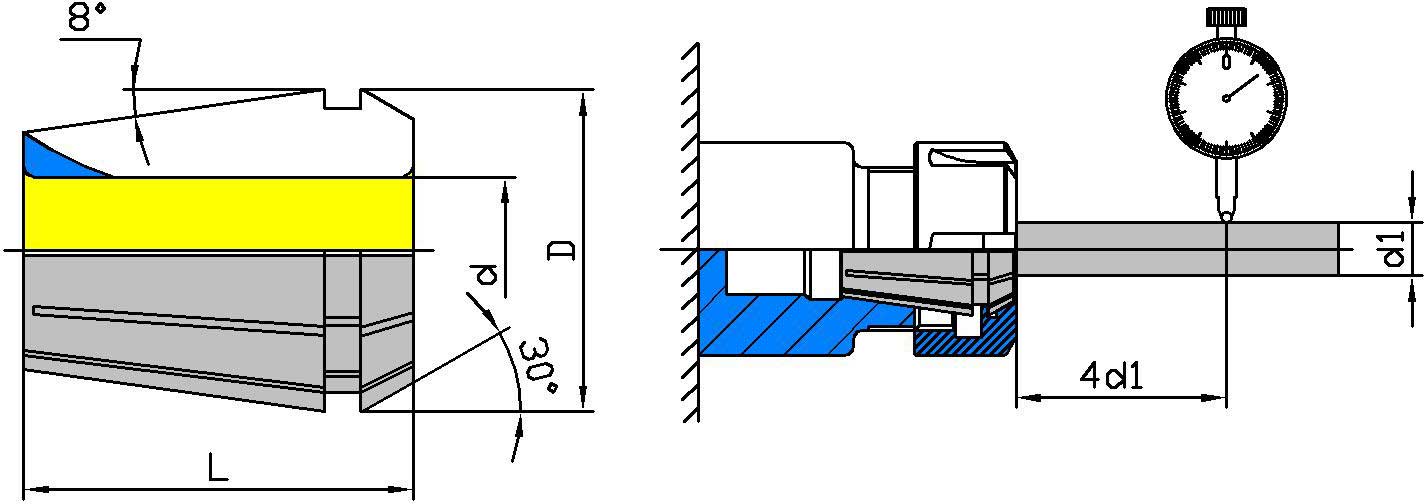

| Collet Series | ER20 |

| Diameter(D) | 13/16" (21mm) |

| Overall Length (L) | 1-7/32" (31mm) |

| Runout | 0.00031" |

| Shape | Round |

| Material Type | Alloy Steel |

| Meas | 1.45 × 1 × 1 in. |

- Technical Parameters

Technical Parameters:

Size (d) | Hole Diameter | Clamping Range |

|---|---|---|

| 1/2 inch | 1/2 inch | 15/32" - 1/2" 0.461" - 0.500" |

| 1/4 inch | 1/4 inch | 7/32" - 1/4" 0.211" - 0.250" |

| 3/8 inch | 3/8 inch | 11/32" - 3/8" 0.336" - 0.375" |

| 3/16 inch | 3/16 inch | 5/32" - 3/16" 0.148" - 0.187" |

| 5/16 inch | 5/16 inch | 9/32" - 5/16" 0.273" - 0.312" |

| 7/16 inch | 7/16 inch | 13/32" - 7/16" 0.398" - 0.437" |

| 5/32 inch | 5/32 inch | 1/8" - 5/32" 0.117" - 0.156" |

| 9/32 inch | 9/32 inch | 1/4" - 9/32" 0.25" - 0.281" |

- Description

1. overall length is 1-7/32" (31mm)

2. Material: high-grade 65Mn

3. Total runout less than .00031 on these precise ER20 collets

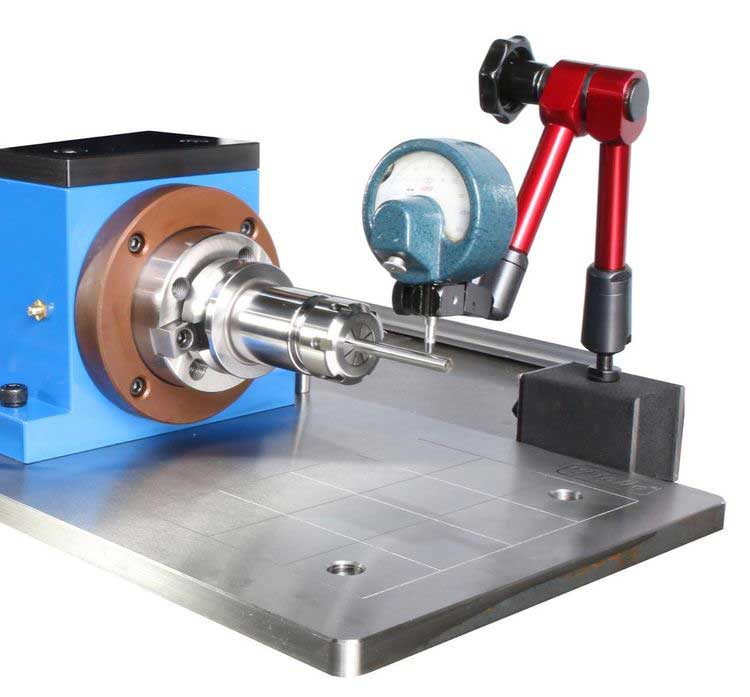

The following schematic diagrams and product pictures are only for reference.

If you have any questions, please contact us.

Runout tolerance within 8 micron (0.00031") at 4×d position

Designed for use with cylindrical shank tools, not flats

The full length of the cutting tool should be placed in the collet

Made from 65Mn Alloy spring steel , vacuum annealing and hardened to HRC 42-45

Each collet gone through thermal aging process to eliminante grinding residual stress and long cryogenic treatment to imoproce wear resistance

Works in all ER20 collet chucks

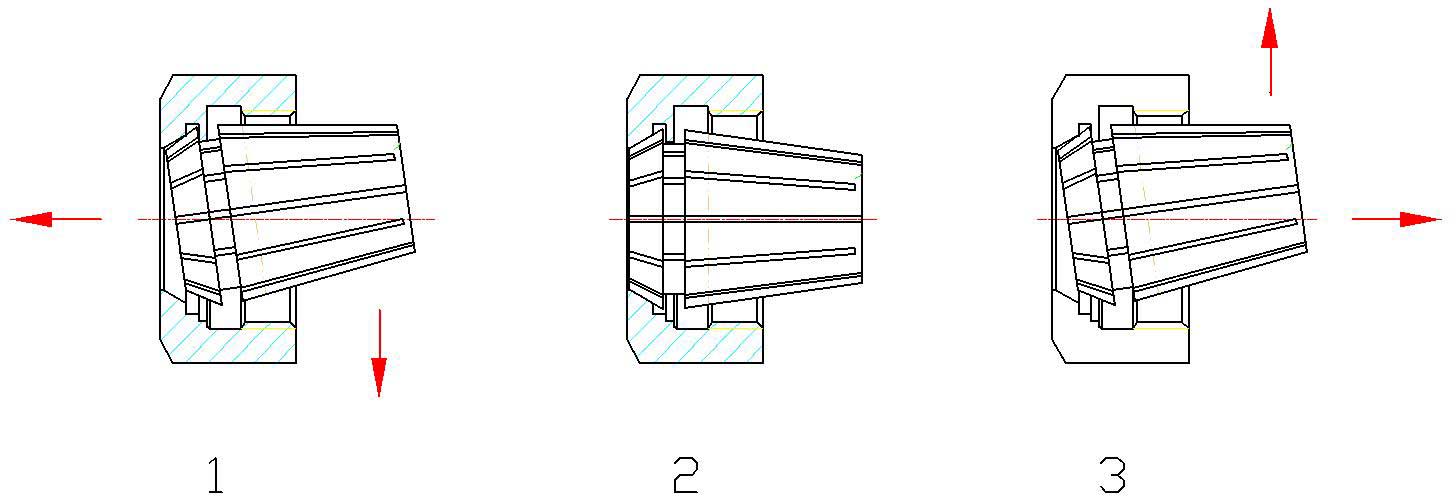

Installation Instruction

1. Put the collet into the nut and gently rotate the nut, then the eccentric part of the nut is in the grooves, and the package is pushed evenly

along the arrow, and it can be loaded into the nut

2. Install the collet and the nut on the shank or machine tool shaft together, wipe the tool cylinder handle into the clamping hole, and tighten

the nut evenly with the wrench, until the tool clamp can be used (Note: install tools before fasten the nut so as not to damage the collet)

3. When changing the tools, release the nut and collet with the wrench, unload the tools, push the collet along the arrow direction, make it

quit, and then change the other collet you needed

- Reviews