1.5 hp (1.1 kW) Air Compressor Motor 115/ 230V 5/8 Shaft

from

$419.54

Ex Tax: $419.54

- Stock: In Stock

- Model: SCJ009588

- SKU: SCJ009588

Products Sold: 0

Product Views: 390

Ask a Question About This Product

- Description

1.5 hp (1.1 kW) Air Compressor Motor 115/ 230V 5/8 Shaft

Brief

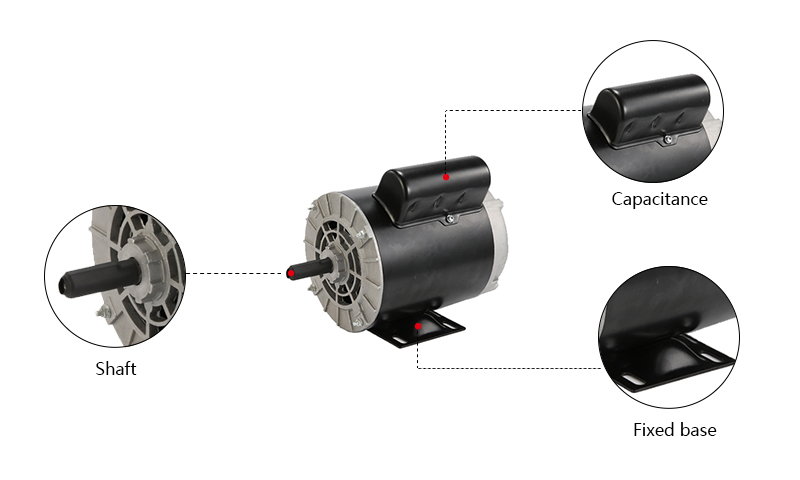

1.5 hp air compressor motor has a compact structure, a small volume and is convenient to carry. Single phase, 115/ 230VAC, 17.4/ 8.7A. It can run at a maximum speed of 3600 RPM, with high work efficiency. Shaft diameter 5/8 (1.59 cm), shaft length 1.88 (4.78 cm).

Description

1.1kW electric motor for air compressor uses high-quality steel materials, which can well protect the engine. And it is equipped with a protector and single capacitance, IP 23, insulation class is F, suitable for air compressors, medical equipment refiners, metal cutting machine tools, etc.

Specification

| Model | SCJ009588 |

| Power | 1.5 HP (1.1 kW) |

| Speed | 3600 rpm |

| Current | 17.4/ 8.7 A |

| Voltage | 115/ 230 V |

| Protector | √ |

| Frame | 56 |

| Shaft diameter | 5/8 |

| Shaft length | 1.88 |

| Capacitance | 1 |

| ENC | ODP |

| Frequency | 60Hz |

| IP | 23 |

| INS | F |

| ROT | CCW |

| Housing material | Steel plate |

| Packing size | 34*27*27cm |

| Weight | 16kg |

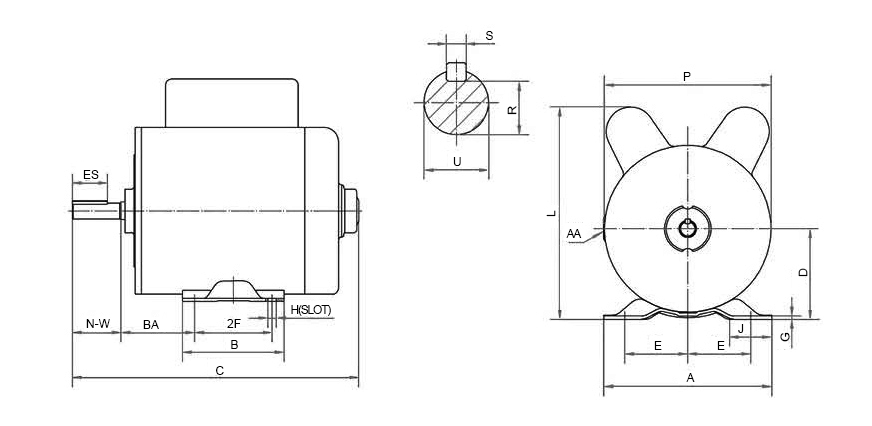

Dimention (Unit: inch)

Details

Tips: Separation method of air compressor motor oil and gas mixture

- Due to the different separation mechanism, the oil-injected screw air compressor unit of the air compressor motor adopts two different methods of oil and gas separation. One is the mechanical method, which is what we often call the collision method or cyclone separation method, which mainly relies on the gravity and centrifugal force of the oil droplets to separate the oil droplets with larger diameters from the gas. The other is the affinity aggregation method. The components made of special materials, generally called oil fine separators or separator cores, make oil droplets with a diameter of less than 1mm first coalesce into oil droplets with a larger diameter. , And then separate it out.

- Nowadays, the air compressor motor unit generally adopts mechanical method as coarse separation, and affinity aggregation method as fine separation. Early mechanical methods generally adopted the collision method, which is to set up some kind of obstacle in the direction of the flow of the oil-gas mixture. When the oil-gas obstacle and the mixture collide, the oil droplets in the mixture will agglomerate on the surface of the obstacle and act on gravity. Down and fall to the bottom of the separator. When the collision method is used, the speed at which the oil-gas mixture hits the obstacle has a certain range, and the optimal value has a lot to do with the density of the gas and the lubricating oil.

- In modern air compressor motor units, cyclone separation or a combination of the two methods are generally used for rough separation. A cyclone passage is set in the oil-gas separator. When the oil-gas mixture enters the oil-gas separator, it first passes through the cyclone passage. Large oil droplets will be thrown under the wall under the action of centrifugal force, and then fall to the separator bottom under the action of gravity.

- Reviews