10 hp (7.5 kW) Air Compressor Motor 208-230V 1-3/8 Shaft

from

$1,212.25

Ex Tax: $1,212.25

- Stock: In Stock

- Model: SCJ009593

- SKU: SCJ009593

Products Sold: 0

Product Views: 379

Ask a Question About This Product

- Description

10 hp (7.5 kW) Air Compressor Motor 208-230V 1-3/8 Shaft

Brief

Lower cost 10 hp air compressor motor shaft has a diameter of 1-3/8 inch and a length of 3.38 inch. 208-230VAC, 48-46A, 3600 rpm, 60Hz. It is IP23 single phase motor with double capacitance. High efficiency, low noise and low vibration.

Description

Buy 3600rpm 7.5kW air compressor motor at affordable price. 213/ 5T frame, steel housing, insulation class is F. It can be used for metal cutting, machine tools, water pumps, blowers, transportation machinery, agricultural machinery, etc.

Specification

| Model | SCJ009593 |

| Power | 10 HP (7.5 kW) |

| Speed | 3600 rpm |

| Current | 48-46 A |

| Voltage | 208-230 V |

| Protector | × |

| Frame | 213/ 5T |

| Shaft diameter | 1-3/8 |

| Shaft length | 3.38 |

| Capacitance | 2 |

| ENC | ODP |

| Frequency | 60Hz |

| IP | 23 |

| INS | F |

| ROT | CW/ CCW |

| Housing material | Steel plate |

| Packing size | 60*38*42cm |

| Weight | 46kg |

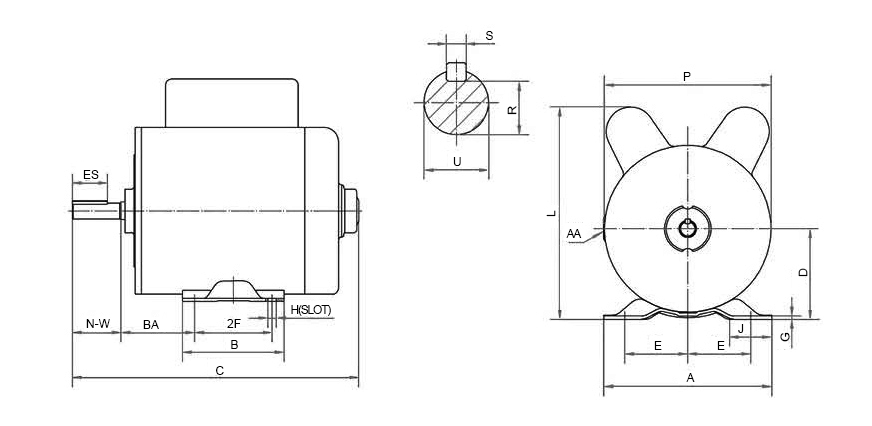

Dimention (Unit: inch)

Details

Tips: Air compressor motor troubleshooting - the motor current is too high

- The air compressor motor temperature controller is faulty, and the temperature controller needs to be replaced.

- The overload protector is faulty, and the overload protector needs to be replaced.

- The air inlet is blocked and needs cleaning and maintenance.

- The drive belt tension is too tight. Loosen the transmission belt, the normal tension of the air compressor is 0.8-1.0cm downward pressure.

- The air filter is blocked and needs to be replaced (when the vacuum value is greater than 5psi).

- The starter contacts are in poor contact, and the starter contacts need to be maintained.

- The oil and gas separator is blocked, and the oil and gas separator needs to be replaced (when the pressure difference is greater than 0.8-1kg).

- If the motor bearing is not oiled, it is necessary to add grease to the motor bearing.

- If the ambient temperature is too high, it is necessary to install ducted exhaust equipment.

- Three-phase voltage is unstable, lack of phase, and voltage is too low (less than 10%). It is recommended to improve the power system.

- The motor bearing is damaged, and the motor needs to be removed for insulation strengthening.

- The motor insulation is poor, and the motor bearings need to be replaced.

- The motor wiring is loose, and the motor wiring needs to be re-locked.

- Reviews