- Stock: In Stock

- Model: SCJ009591

- SKU: SCJ009591

Ask a Question About This Product

- Description

5 hp (3.7 kW) Air Compressor Motor 208-230V 7/8 haft

Brief

Description

SOCOJE one-phase 3.7 kW ac air compressor electric motor is suitable for air compressors, medical equipment refiners, food machinery, etc.

Specification

| Model | SCJ009591 |

| Power | 5 HP (3.7 kW) |

| Speed | 3600 rpm |

| Current | 22-21 A |

| Voltage | 208-230 V |

| Protector | √ |

| Frame | 143/ 5T |

| Shaft diameter | 7/8 |

| Shaft length | 2.25 |

| Capacitance | 2 |

| ENC | ODP |

| Frequency | 60Hz |

| IP | 23 |

| INS | F |

| ROT | CCW |

| Housing material | Steel plate |

| Packing size | 40*27*27cm |

| Weight | 25kg |

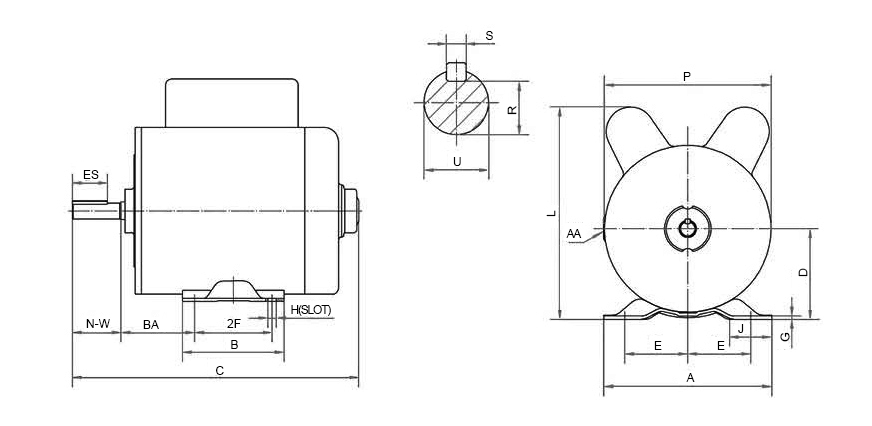

Dimention (Unit: inch)

| Frame | E | 2F | H | BA | A | B | C | D | L | J | P | G | AA | S | ES | R | N-W | U |

| 145T | 2.44 | 3 | 0.34 | 2.75 | 6.5 | 4 | 13.98 | 3.5 | 7.95 | 1.73 | 6.46 | 0.12 | 0.5 | 0.188 | 1.41 | 0.771 | 2.25 | 0.875 |

Details

Tips: Reasons for the overhaul of the air compressor motor head bearing

With the running time of the air compressor motor, the bearings of the motor host will inevitably wear out, which will cause the screw to produce axial movement and increase the radial displacement. This change will change the gap between the screw and the screw, between the screw and the main body housing and the front and rear ends. These gap changes are allowed within the life of the bearing, and the resulting air compressor electric motor gas production attenuation and main motor load increase are also normal.

The general reasons for the overhaul of the head bearing of the air compressor motor:

- The operating load of the main engine increases, causing harm to the main motor and electrical system. The possible strong friction between the screws of the main engine, between the screw and the front and rear ends, and between the screw and the main engine housing will cause the main engine's operating load to increase sharply, and the operating load of the severely worn bearings is also very large. In this way, the air compressor motor will be in an overload working state, which will seriously endanger the safe operation of the air compressor motor. If the electrical protection device of the air compressor motor unit does not respond sensitively or fails, it may cause the motor to burn out.

- The electric motor for air compressor exhaust volume will be greatly attenuated. The increase in the matching clearance of the main engine will cause a serious decrease in the efficiency of the main engine, which will have a certain impact on the normal production of the gas user. Especially for users with small air compressor motor displacement, when the air consumption is relatively stable, the compressed air pressure of the pipe network will drop a lot, and the air system equipment may not work normally or not work at all. As a result, it may affect unit production or cause temporary suspension of production, causing losses to the enterprise.

- Reviews