818 5 Axis CNC Tool Grinding Machine For Medical Automotive High Precision Instruments

from

$123,999.00

Ex Tax: $123,999.00

5 or more $122,999.00

10 or more $121,999.00

- Stock: In Stock

- Model: SCJ007271

- SKU: SCJ007271

Products Sold: 0

Product Views: 270

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| CNC or Not | CNC |

| Place of Origin | Shanghai, China |

| Weight (KG) | 5000 |

| warranty: | 1 Year |

| Key Selling Points | 5-Axis CNC |

| Showroom Location | None |

| Applicable Industries: | Manufacturing Plant, Construction worksxa0, Energy & Mining, Machinery Repair Shops, Building Material Shops |

| Marketing Type | New Product 2023 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Wheel Size(mm) | 75~150mm |

| Core Components | Motor, Bearing, Engine, Other |

| Voltage | AC 380V |

| Dimension(L*W*H) | Inquiry us |

| X-Axis Travel | 450mm |

| Power (kW) | 22.5 |

| Y-Axis Travel | 350mm |

| After-sales Service Provided | Yes |

| Packing | Factory Standard |

| Year | 2023 |

| Z-Axis Travel | 250mm |

| A-Axis Max.speed | 400rpm |

| B-Axis Max.speed | 100rpm |

| Rapid traverse X.Y.Z | 7.5 m/min |

| Type | Tool Grinding Machine |

| Clamping diameter range | 3-20mm(32mm for optional choice) |

| PAYMENT | T/T |

| Packaging and delivery | |

| Packaging Details | Factory ordinary packaging, please confirm with the ANTISHI for more details. |

| Supply Ability | |

| Supply Ability | 300 Set/Sets per Month |

- Description

Product Description

Specification

Specifications | C818 Minipower |

X-Axis | CNC 5-axis linkage linear axis Servo Motor:Taiwan SYNTEC Power: 3.1KW (absolute value) Stroke: 450mm CNC system resolution: 0.001mm Min.resolution of programming and handwheel feed: 0.001mm, Screw:THK BNFN32-C3 , Guide rail: MR35-G1 Repeat positioning accuracy: 0.003mm |

Y-Axis | CNC 5-axis linkage linear axis Servo Motor:Taiwan SYNTEC Power: 3.1KW (absolute value) Stroke: 350mm CNC system resolution: 0.001mm Min.resolution of programming and handwheel feed: 0.001mm, Screw:THK BNFN32-C3 , Guide rail: MR35-G1 Repeat positioning accuracy: 0.003mm |

Z-Axis | CNC 5-axis linkage linear axis Servo Motor:Taiwan SYNTEC Power: 3.1KW (absolute value) Stroke: 250mm CNC system resolution: 0.001mm Min.resolution of programming and handwheel feed: 0.001mm, Screw:THK BNFN32-C3 , Guide rail: MR35-G1 Repeat positioning accuracy: 0.003mm |

A-Axis | CNC 5-axis simultaneous workpiece rotation axis DD Servo Direct Drive Power: 0.879KW Rated TR=28Nm(7.5A) Max TM=56Nm(16.5A) Indexing accuracy: 2 arc seconds (0.0005 degree) Rated speed:300rpm Max.speed:400rpm、 CNC system resolution: 0.001 degree Minimum resolution for programming and handwheel feed: 0.001 degree Infinite rotation, dividing head body: Radial runout:0.001-0.005mm Runout:0.001-0.005mm Rotary encoder:Renishaw,United Kingdom |

B-Axis | CNC 5-axis simultaneous workpiece rotation axis DD Servo Direct Drive Power: 0.942KW(7.5A) Rated TR=120Nm(6.8A) Max TM=380Nm(27A) Indexing accuracy: 2 arc seconds (0.0005 degree) Rated speed:50rpm Max.speed:100rpm、 CNC system resolution: 0.001 degree Minimum resolution for programming and handwheel feed: 0.001 degree Circumferential rotation to 360 degrees, -180 degrees + 180 degrees Rotational positioning accuracy: 0.001 degrees Rotary encoder:Renishaw,United Kingdom |

Rapid traverse X.Y.Z | 7.5 m/min |

Clamping Min. workpiece diameter | 3mm |

Clamping Max. workpiece diameter | 20mm (Optional SCHUNK SK50-20, the max. diameter that can be clamped: 32mm) |

Clamping Max. workpiece length | 200mm |

Min. workpiece diameter for main grinding | 1mm |

Max. workpiece diameter for main grinding | 12mm |

Max. cutting edge length for main grinding | More than 160MM |

Max. workpiece weight for main grinding | 5kg |

Shank form | Schoberlin W25 or SCHUNK BT50 SK50-20/ 15 (customer's choice) |

linear resolution | 0.001mm |

Linear Repeatability Positioning Accuracy | 0.003mm |

Rotation Resolution | 0.001mm |

Rotation Repeat Positioning Accuracy | 0.001 degree |

Spindle power | Standard configuration 15kw (permanent magnet variable frequency motor constant torque) |

Grinding wheel rod form | HSK50F-31.75mm or 20mm |

Wheel diameter | 75~150mm |

Grinding wheel spindle speed | 4000~8000rpm stepless adjustable: drive |

Machine weight | About 5000kg |

Total power | ≤22.5kw |

Sliding angle of ram | 0~8° |

Payment | T/T |

Package | Foctory standard |

After-sales Service Provided | Yes |

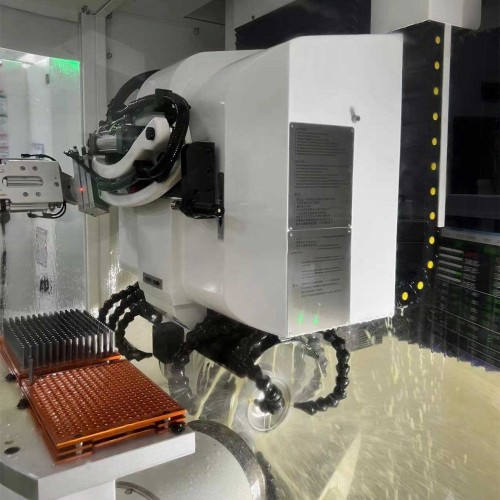

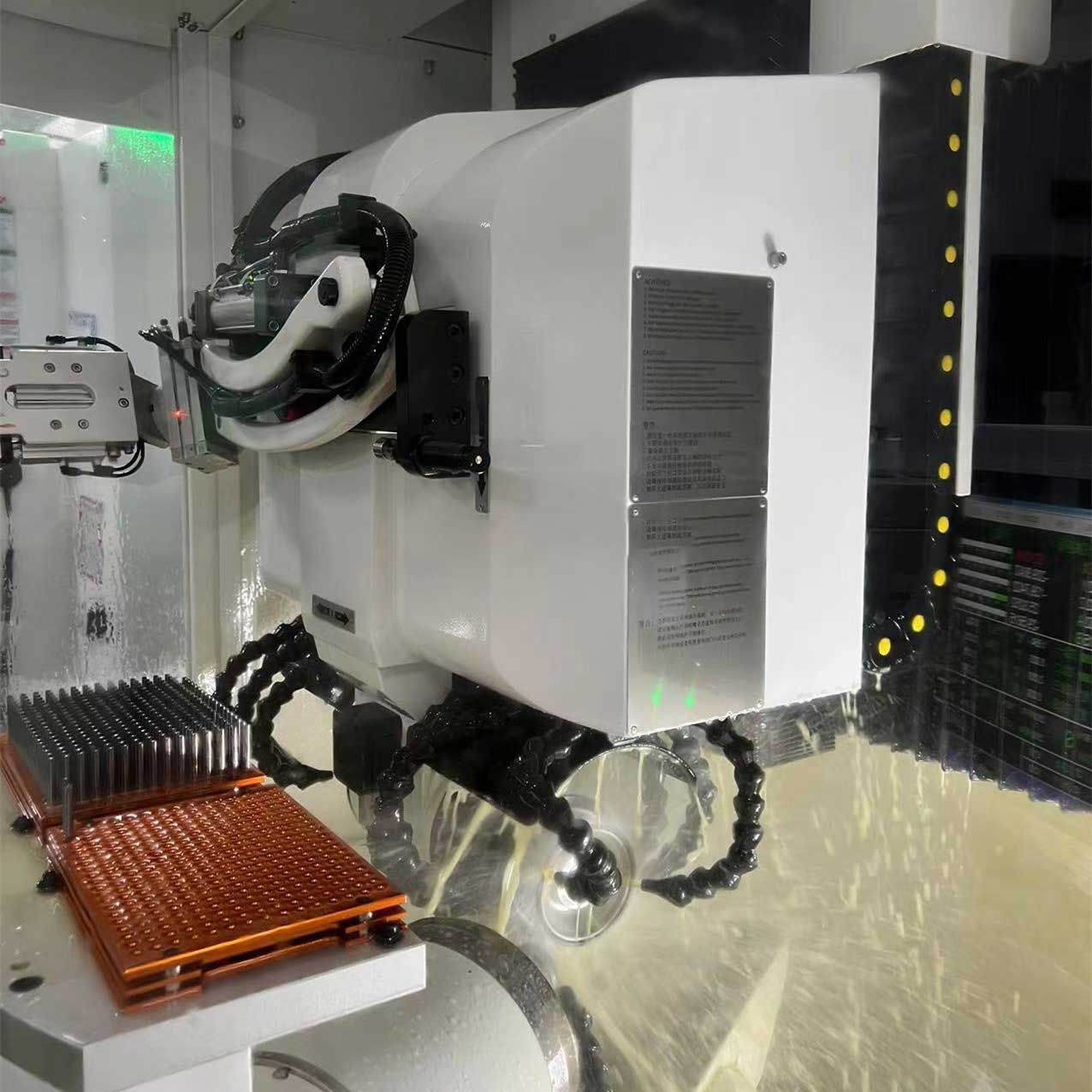

ANTISHICNC 818 5 Axis CNC Tool Grinding Machine Detailed introduction

The machine is designed based on the experience of the German 5-axis CNC tool grinding machine (WRT) and the actual operation experience of the designers, as well as exchanges at the cutting tool production site. It is reflected in practicality, economy, operation, maintenance, stability and high efficiency.

The machine tool adopts an integral imported plexiglass round door, which is convenient for unlimited operation and maintenance of the machine tool. The fully enclosed protective cover meets production safety. In order to cope with the production of special tools, the relative positional relationship of the servo axis of the equipment can be optimized. Mechanism corresponding to machining of various tools.All axes adopt imported servo motors and screw guide rails with high precision and resolution to ensure high production efficiency and quality of cutting tools.

ANTISHICNC 818 5 Axis CNC Tool Grinding Machine Operating System Features

1. Operating environment: special tool software (version 4.1), with simulation operation software.

2. Display screen description: 17-inch LCD screen, which displays the machine coordinates, relative coordinates, absolute coordinates, execution of processing formulas and other operation dialog frames on the screen.

3. Interface description: The tool processing special software (version 4.1) includes, diameter, number of threads (number of grooves), helix angle, length of groove, speed of groove, depth of groove (increment of groove depth) adjustment), screw direction (left-handed, right-handed).

4. Keyboard: Membrane button keyboard, letter and number keys are integrated with the display.

5. Hard disk: 256G

6. Control system: Taiwan SYNTEC.

7. Data input and output methods == keyboard input, computer connection.

8. Simulation: 2D simulation, 3D simulation, 3D collision check, you can see the shape of the processed material, and modify the parameters according to the parameters obtained after simulation.

9. Package function:

(1) Milling cutter software package: (including standard milling cutter, unequal milling cutter, unequal helix angle milling cutter, variable lead milling cutter, rough skin milling cutter, cone

degree milling cutter, dovetail milling cutter, multi-edge milling cutter, tapered ball end milling cutter, etc.)

(2) Drill software package: (including 18 kinds of drill tip shape software, twist drill, step drill, drill milling cutter, step drill milling cutter, plunge milling cutter, gun drill, sudden drill, chamfering cutter, centering drill, etc.)

(3) Forming knife software package: (including all kinds of DXF spline curve anti-profile knife, T-shaped milling cutter, etc.)

(4) Rotary file software package: (including flat rotary file, taper rotary file, ball-end rotary file, rounded circular file, DXF forming rotary file, etc.)10. Use the latest version, leaving room for upgrades, which can be upgraded.

ANTISHICNC 818 5 Axis CNC Tool Grinding Machine Standard Equipments

Machine body

CNC SYNTEC control system and servo unit

Tools software package

Renishaw Universal probe

HSK grinding wheel flange

Round arc sealed hood

Mobile hand pulse with magnet

clamping device

Grinding wheel and flange

Double grinding head

Special driver for permanent magnet motor

Sealed Oil Resistant LED Lamp

ANTISHICNC 818 5 Axis CNC Tool Grinding Machine Optional Equipments

SCHUNK fixtures

SCHUNK handle

ANTISHICNC 818 5 Axis CNC Tool Grinding Machine Main Parts

Name | Origin | Manufacturer/Specification |

X-axis ball screw | Taiwan | THK |

Y-axis ball screw | Taiwan | THK |

Z-axis ball screw | Taiwan | THK |

X-axis rail | Taiwan | THK |

Y axis rail | Taiwan | THK |

Z axis rail | Taiwan | THK |

A axis Workpiece rotary indexing axis | Taiwan | DD direct drive |

B axis rotary indexing axis | Taiwan | DD direct drive |

Universal probe | Uk | Renishaw |

- Reviews