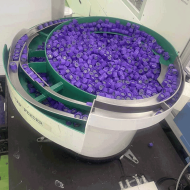

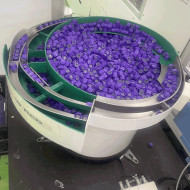

Double Track Vibration Bowl Feeder Auto Feeding Rubber Coated Vibratory Bowl Feeder Vibratory Bowl Feeder

from

$900.00

Ex Tax: $900.00

5 or more $850.00

- Stock: In Stock

- Model: SCJ002511

- SKU: SCJ002511

Products Sold: 0

Product Views: 180

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| Place of Origin | Zhejiang, China |

| Weight (KG) | 60 |

| Showroom Location | None |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

| Marketing Type | Hot Product 2022 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump |

| Frequency | 50Hz/60Hz |

| Voltage | 220V / 110V |

| Product name: | coated vibrating plate |

| Size | Custom |

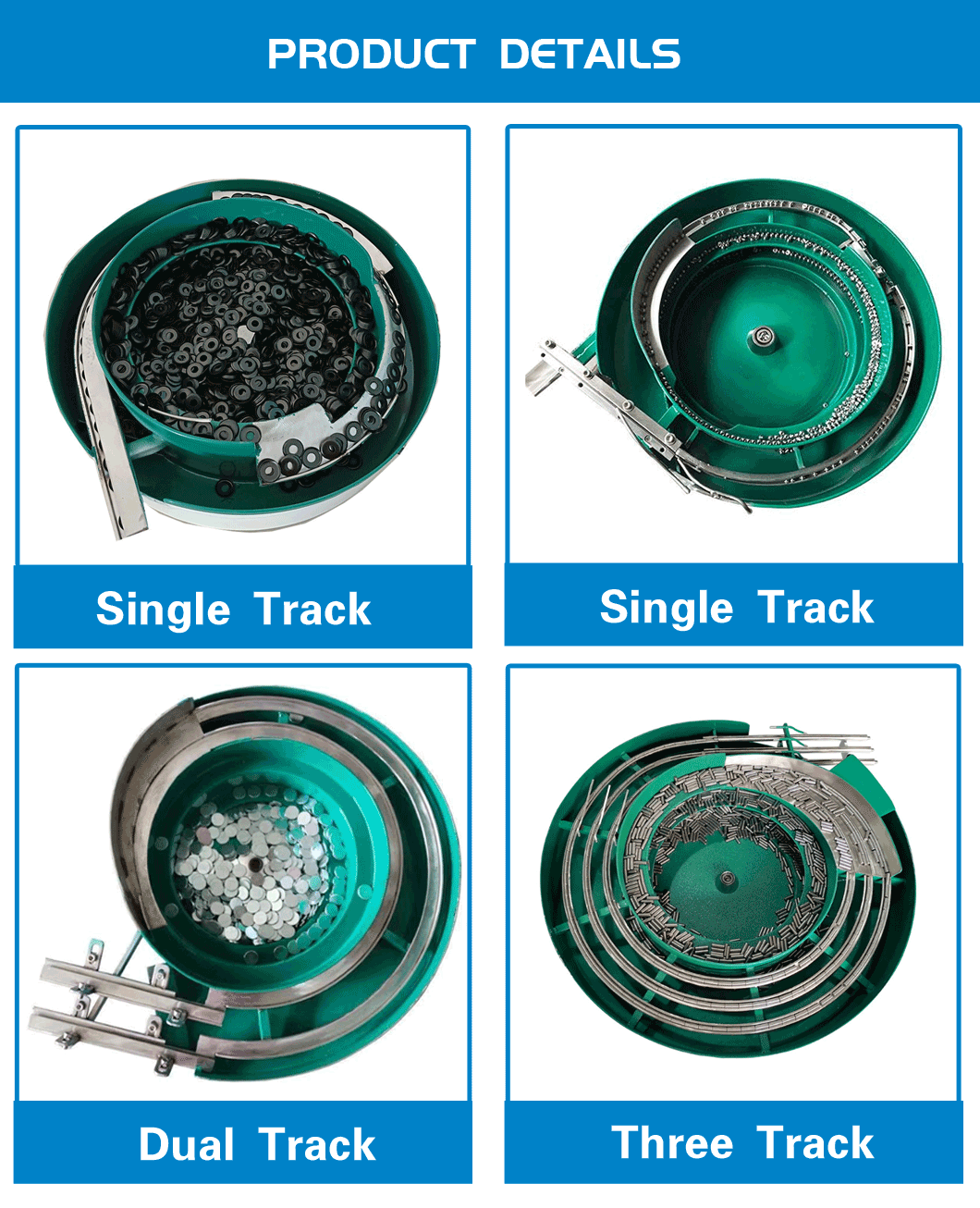

| Type | Coated/precision vibrating plate |

| Function | Automatic Feeding |

| Advantage | save time and labour |

| Keyword: | time saving |

| Color | Customer Requirement |

| Certificate: | CE Certificated |

| Packaging and delivery | |

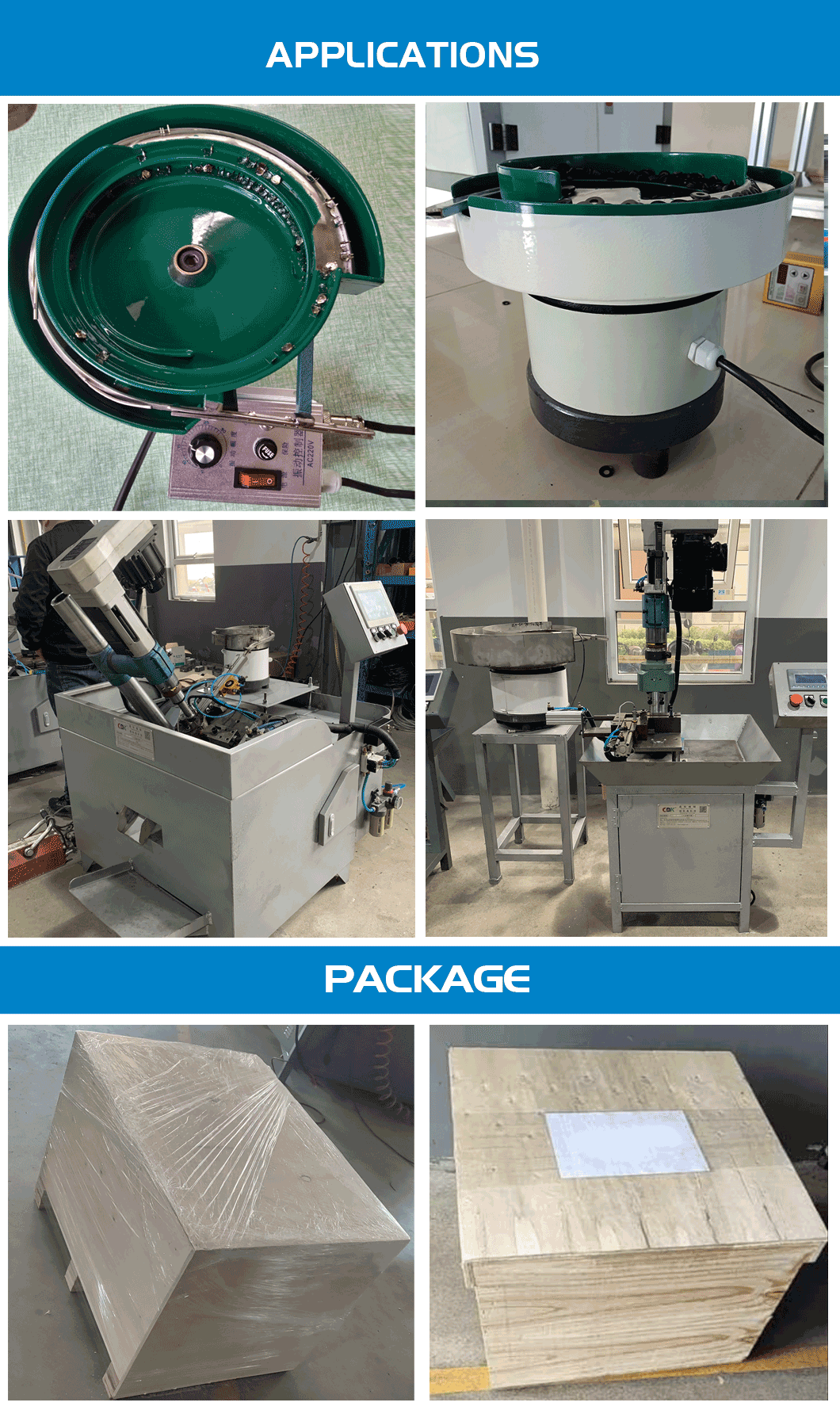

| Packaging Details | Each vibrating plate is wrapped with stretch film or packed in a wooden box. |

| Port | ningbo/shanghai/shenzhen |

| Supply Ability | |

| Supply Ability | 500 Set/Sets per Month |

- Description

Product Description

Double Track Vibration Bowl Feeder Auto Feeding Rubber Coated Vibratory Bowl Feeder Vibratory Bowl Feeder

Specification

item | value |

Place of Origin | China |

Condition | New |

Weight (KG) | 60 |

Product name | coated vibrating plate |

Function | Automatic Feeding |

Keyword | time-saving |

Type | Coated/precision vibrating plate |

Voltage | 220V / 110V |

Frequency | 50Hz/60Hz |

Certification | CE Certificated |

Size | Custom |

Advantage | save time and labor |

Color | Customer Requirement |

Each welder robot is wrapped with stretch film or packed in a wooden box.

1. The best choice for fully automatic processing

2. High efficiency, low failure rate, easy operation

3. Save labor and save time

4. Spray as required to avoid damage to the product surface

- Reviews