- Stock: In Stock

- Model: SCJ006499

- SKU: SCJ006499

Ask a Question About This Product

- Description

About this product

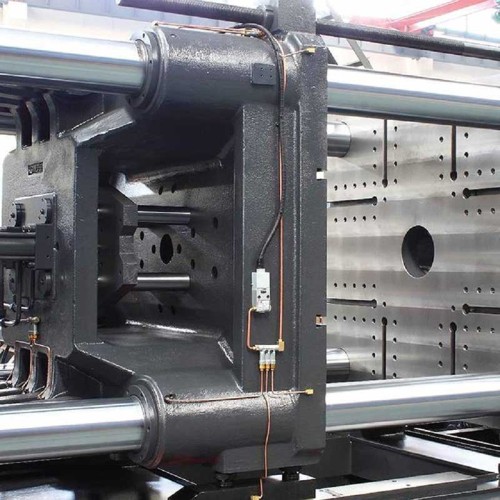

1. Clamping Force 2700 KN

2. Opening stroke 21.26 inch

3. Space between tie-bars (W × H) 22.44× 22.44 inch

4. Max. mold height 21.65 inch/ Min. mold height 7.87 inch

5. Servo motor with higher efficiency and quicker response

6. Machine dimension 232.28 × 62.99 ×149.61 inch

Product Description

Product Description

PRICE QUOTED INCLUDES INITIAL ONSITE SETUP/INSTALLATION, MOLD QUOTATION SERVICES, ROBOTIC AUTOMATION CONSULTATION, AND A MACHINE SELECTION CONSULTATION.

WE ARE HAPPY TO PROVIDE YOU TAILORED SERVICE IF YOU CAN BRING UP WITH SPECIFIC REQUIREMENTS.

Excellent Molding Stability

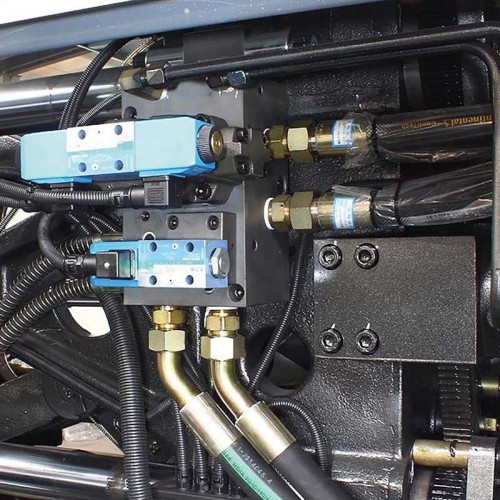

The servo driving system has its pressure and flow under closed loop control; and compared with traditional injection molders, its molding repetition precision is improved substantially.

Constant Oil Temperature

The servo motor output hydraulic oil proportionately to prevent excessive heat.It can achieve substantial water saving even without cooling.

Rapid Response

The servo driver features rapid response whose rapid starting time is improved by 50% compared with traditional injection.

Substantial Energy Saving

Under the same conditions, it can save 20%-80% energy compared with traditional constant delivery pump injection molders.

High Performance Environmental Protection

The complete machine features low operating noise, and even quieter during low-speed operation.

Product Information

Technical Details

| K-TEC270H | |||||

| VB | in3 | 66.211 | |||

| A | B | C | |||

| Injection Unit | Screw Diameter | inch | 1.772 | 1.969 | 2.165 |

| Screw L/D Ratio | L/D | 23.4 | 21.0 | 19.1 | |

| Injection Volume | in3 | 24.23 | 29.90 | 36.19 | |

| Shot Weight(PS) | OZ | 12.769 | 15.732 | 19.048 | |

| Injection Rate | in3/S | 7.57 | 9.40 | 11.35 | |

| Injection Pressure | Psi | 30023 | 24366 | 20015 | |

| Screw Speed | rpm | 260 | |||

| Clamping Unit | Clamping Force | KN | 2700 | ||

| Opening Stroke | inch | 21.26 | |||

| Space Between Tie-Bars(WxH) | inch | 22.44×22.44 | |||

| Max. Mold Height | inch | 22.83 | |||

| Min. Mold Height | inch | 7.87 | |||

| Ejector Stroke | inch | 5.91 | |||

| Ejector Force | KN | 70 | |||

| Others | Max. Pump Pressure | Psi | 2321 | ||

| Motor Power | KW | 43 | |||

| Heater Power | KW | 16.8 | |||

| Machine Dimension | in | 236.22×62.99×88.58 | |||

| Oil Tank Capacity | in3 | 23189 | |||

| Machine Weight | lbs | 19401 | |||

| Available Voltage | 380V/440V/460V/480V/530V- 3 Phase 60Hz | ||||

| Rated Current | 40.8A | ||||

Additional Information

Spare Parts (FREE) List of Plastic Injection Molding Machine

Sequence | Parts name | Quantity |

1 | "O" Ring | 1 Set |

2 | Seal Ring | 1 Set |

3 | Wrench | 2 Sets |

4 | Barrel Heater | 2 Pcs |

5 | Screw Head Heater | 1 Pc |

7 | Balance pad | 1Set |

8 | Extended nozzle | 1 Pc |

9 | Thermocouple | 2 Pcs |

10 | Contactor | 1 Pc |

11 | Machines manual | 1 Pc |

12 | Moulds Clamp | 1 Set |

Main Configuration of Konger 2016 | |||

No. | Parts | Brand | Socoje |

1 | Controller | Keba | Austria |

2 | Electron Components | Schneider | France |

3 | Switch | Schneider | France/Japan |

4 | Position Transducer (electronic ruler) | Novo | Germany |

5 | Motor | Phase | Italy |

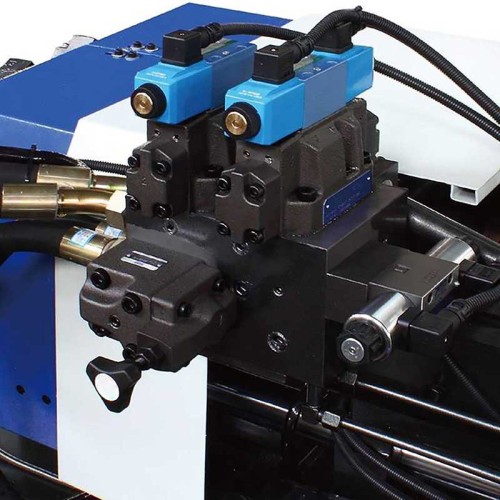

6 | Pump | Sumitomo | Japan |

7 | Servo Driver | Inovance | China |

9 | Valve | Vickers | USA |

10 | Seal Ring | Hallite | UK |

- Reviews