- Stock: In Stock

- Model: SCJ009325

- SKU: SCJ009325

Available Options

Ask a Question About This Product

- Description

2 kW AC Vibration Motor, 3 Phase, 6 Pole, 220V

Brief

Description

220 Volt AC vibration motor, three phase, 6 pole, frequency 50/60 Hz, 5.5 Amps rated current, excellent stator insulation performance, long service life of the motor.

Specification

| Model | SCJ009325 |

| Phase | 3 Phase |

| Pole | 6 Pole |

| Force | 2762 Kg, 38 kN |

| Speed | 970 rpm |

| Power | 2000W (2 kW) |

| Current | 5.5A |

| Voltage Class | 3 Phase 220V 50Hz/380V 50Hz |

| Weight | 206.5 kg |

| Frame No. | 80 |

| Frequency | 50 Hz/60 Hz |

| Protection Rank | IP65 |

| Insulation Class | F |

| Certificate | CE |

| Warranty | 12 Months |

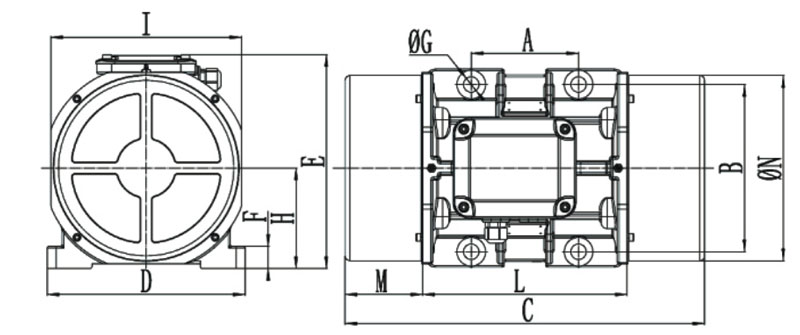

2 kW Three Phase Vibration Motor Dimension (unit: mm)

| A | B | C | D | E | F | G | H | I | L | M | N | Cable Gland |

| 180 | 280 | 683 | 332 | 360 | 37 | 26 | 168 | 320 | 343 | 170 | 310 | M32*1.5 |

3 Phase AC Vibration Motor Structure

Tips: Vibration motor controller vibration control system

The vibration motor controller control system consists of two parts. One controller is used to compensate the engine torque pulsation when the engine is started, and the other is used to control the torsional vibration of the drive shaft and the drive shaft due to the rapid increase and decrease of drive torque. Vibration motor controllers vary according to the method they use to detect the rotor position. Measurements can be made with the help of position sensors or using sensorless technology.

The vibration motor controller is used to adjust the speed and torque of the vibration motor. It can also start, stop and reverse its rotation. The vibration motor controller detects the position of the rotor by using a sensor or no sensor. The sensor measures the position of the rotor and sends this data. The controller receives the information and enables the transistor to switch the current at the appropriate time and energize the required stator winding.

- Reviews