A drilling machine is a machine tool used to drill holes in workpieces. It is usually used for drilling small-sized holes with moderate precision requirements. During drilling, the workpiece is generally fixed, and the tool rotates as the main motion while feeding axially. Drilling machines can perform tasks such as drilling, reaming, tapping, and thread cutting, with the maximum parameter being the maximum drill hole diameter. The main types of drilling machines include bench drilling machines, vertical drilling machines, radial drilling machines, and deep-hole drilling machines.

Vertical Drilling Machine:

It mainly consists of the spindle box, feed box, worktable, column, and base. During processing, the workpiece is directly installed on the worktable or through fixtures. The spindle is rotated by the motor through the speed change system to achieve the main rotary motion. At the same time, the feed box moves the spindle axially with the spindle sleeve for feeding. The worktable and speed change box can be adjusted up and down along the column to adapt to the requirements of processing different height workpieces. Additionally, the control mechanism installed in the speed change box can enable manual quick lifting, manual feeding, and switching of the motorized feed.

After processing a hole on a vertical drilling machine, when processing another hole, it is necessary to move the workpiece to align the tool with the center of the hole being processed, which is inconvenient. Therefore, vertical drilling machines are suitable for processing small and medium-sized parts in single-piece or small-batch production.

There are variations of vertical drilling machines, such as multi-head vertical drilling machines and line-type multi-axis vertical drilling machines. They are equivalent to combinations of several single-axis vertical drilling machines and are used for sequentially drilling, reaming, and tapping different diameter holes on the same workpiece. Since it saves time for tool changes, it is mainly used in small-scale and small-batch production.

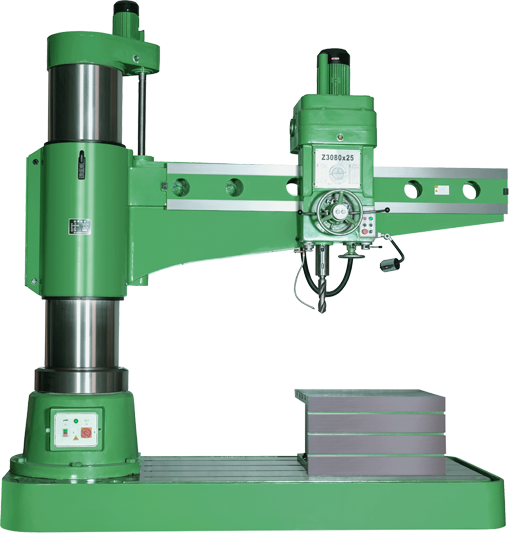

Radial Drilling Machine:

A radial drilling machine is a drilling machine with an arm that rotates around a column, and the spindle box moves horizontally on the arm. It is widely used in the processing of large and medium-sized parts. It mainly consists of inner column, outer column, arm, spindle box, and base. The spindle box is mounted on the arm and can move horizontally along the guide rail on the arm. The arm is mounted on the outer column and can move up and down along the outer column to adapt to the requirements of processing different height workpieces. In addition, the arm can rotate around the inner column within a 180-degree range with the outer column, so the spindle can be easily adjusted to the required processing position. To keep the spindle in a determined position during processing, the radial drilling machine should have clamping mechanisms for the column, arm, and spindle box, which can quickly clamp them after the position of the spindle is adjusted.

Other variations of radial drilling machines include universal radial drilling machines, where the arm and spindle box can rotate or tilt, allowing the spindle to perform drilling in any direction in space. This type of machine tool is suitable for heavy machinery, locomotives, ships, boilers, and other industries for processing large workpieces.

CNC drilling machines are mainly used for processing holes and hole systems with positional accuracy requirements. They can perform operations such as drilling, reaming, tapping, and threading. The X, Y, and Z axes are controlled by CNC systems and stepper motors, with high torque and positioning accuracy. This series of machine tools has good rigidity, simple programming, convenient operation, reliable use, and is suitable for all industries, especially for medium and small batches and multiple varieties of mechanical processing.

Leave a comment