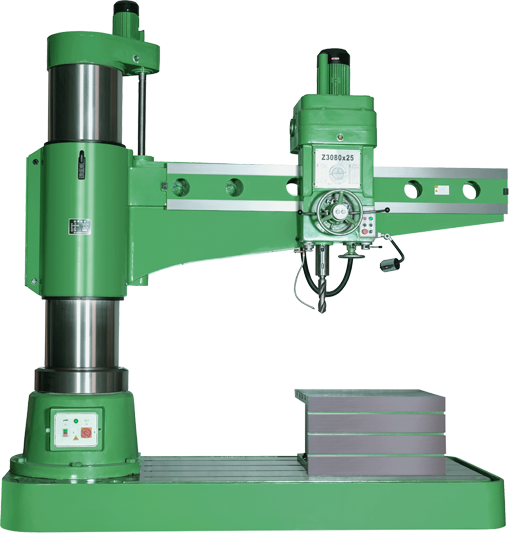

Radial Drilling Machines:

Radial drilling machines can generally be divided into two types: hydraulic radial drilling machines and mechanical radial drilling machines.

However, whether hydraulic or mechanical, radial drilling machines require manual control of their operations, making them semi-automatic machining machines.

The rigidity of the machine tool itself is relatively low, and it cannot achieve complete multi-axis linkage during processing. This makes it difficult to achieve quality processing for some complex-shaped workpieces. Moreover, when changing materials for processing, adjustments need to be made to each spindle, increasing the preparatory work before operation, increasing labor intensity, and reducing work efficiency.

Generally, CNC drilling machines are controlled and processed by CNC systems, which can be said to be fully automatic processing.

As long as the CNC system is set up properly, it can achieve automatic processing of workpieces, reducing labor intensity. The machine tool itself has high precision and rigidity, and can achieve multi-axis linkage during processing, ensuring a certain processing quality for materials with complex shapes. When processing different parts, only the CNC system needs to be changed, saving preparatory work before processing.

Advantages of CNC Drilling Machines:

- CNC drilling machines are more efficient than ordinary drilling machines, with a productivity of more than 6 times that of ordinary drilling machines.

- CNC drilling machines can be operated by one person for multiple machines, realizing automated production lines, which is convenient for manufacturers to arrange the process of workpieces.

- Daily maintenance of CNC drilling machines is relatively easy, eliminating the need for regular maintenance of ordinary machine tools.

- Since the machine tool is controlled by the CNC system, the personal skills required for machine tool operators are reduced.

Leave a comment