An actuator is a component that completes the control action on the controlled object based on control information from the controller. It converts electrical or fluid energy into mechanical energy or other forms of energy, altering the mechanical movement state or other states (such as temperature, pressure, etc.) of the controlled object according to control requirements. It acts directly on the controlled object, functioning as the "hands" and "feet." In pneumatic systems, this primarily refers to various types of cylinders.

Types of Cylinders

1.Linear Types

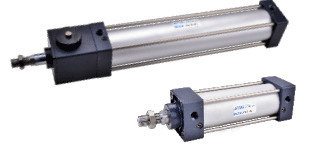

Standard Cylinders, Thin Cylinders, Mini Cylinders

Locking Cylinders: With lock, air-off lock, air-off protection (multi-point positioning, movable limit)

Multi-position Fixed Cylinders: Various installation methods

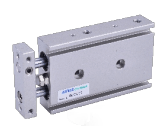

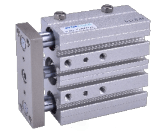

Dual Rod Cylinders: Double output force, capable of bearing certain bending moments

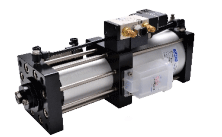

Triple Rod Cylinders: Characterized by guide rods

Slide Cylinders, Panel Cylinders, Threaded Cylinders

2.Rotary Types

Rotary Cylinders, Rotary Clamping Cylinders

3.Functional Cylinders

Pneumatic Fingers, Stopper Cylinders, Large Diameter Open Clamps

Welding Clamping Cylinders, Blade Eject Cylinders

The positioning accuracy of a cylinder depends on the limiting mechanism. For applications requiring high output force and speed, limits must be added. Reason: To prevent excessive impact of the piston, which can easily damage the cylinder cap (small pistons and short-stroke cylinders rely on their own resistance).

Leave a comment