-

Your shopping cart is empty!

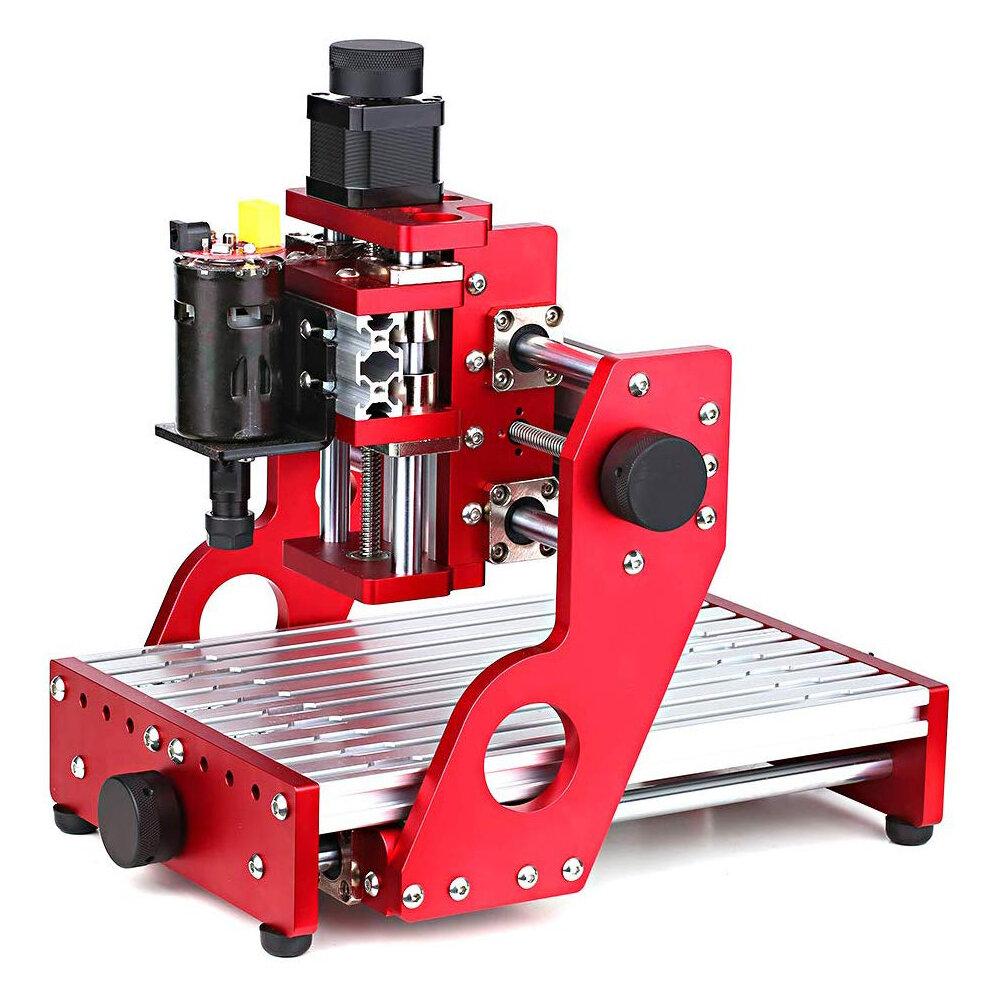

Machining Fundamentals Part 2: Advanced Technology and Precision Machining with CNC Lathe

Equipment Introduction

A CNC lathe, also known as a turning center, is a highly precise and efficient automated machine tool. Equipped with a multi-station turret or power turret, the machine has a wide range of processing capabilities. It can handle various complex workpieces including straight cylinders, tapered cylinders, arcs, and various types of threads, grooves, and worms. It features linear interpolation, circular interpolation, and various compensation functions, delivering good economic effects in batch production of complex parts.

CNC lathes utilize digital signals controlled by programmable automation to manage the equipment’s operation and the machining process. This control extends to position, angle, speed, and force signals generated during machining; that is, it processes workpieces automatically according to a pre-programmed machining procedure.

Equipment Features

High machining precision with stable processing quality.

Capable of multi-axis linkage to process complex parts.

When machining different parts, generally only the CNC program needs to be changed, which enhances work efficiency.

The machine itself has high precision and rigidity, allowing for the selection of favorable machining parameters, thus ensuring high productivity.

High degree of automation, reducing labor intensity.

High performance with low noise levels.

Processing Types

Compared to conventional lathes, CNC lathes not only perform automated turning but can also handle tasks such as multiple lead threads, variable pitch threads, and irregular arcs which are beyond the capabilities of conventional lathes.

Processing Accuracy

The machining accuracy can reach up to IT6, with a surface roughness of up to Ra1.6um.

Processing Materials

Materials such as carbon steel, stainless steel, aluminum alloys, brass, maraging steel, PEEK, ABS, and more.

Leave a comment