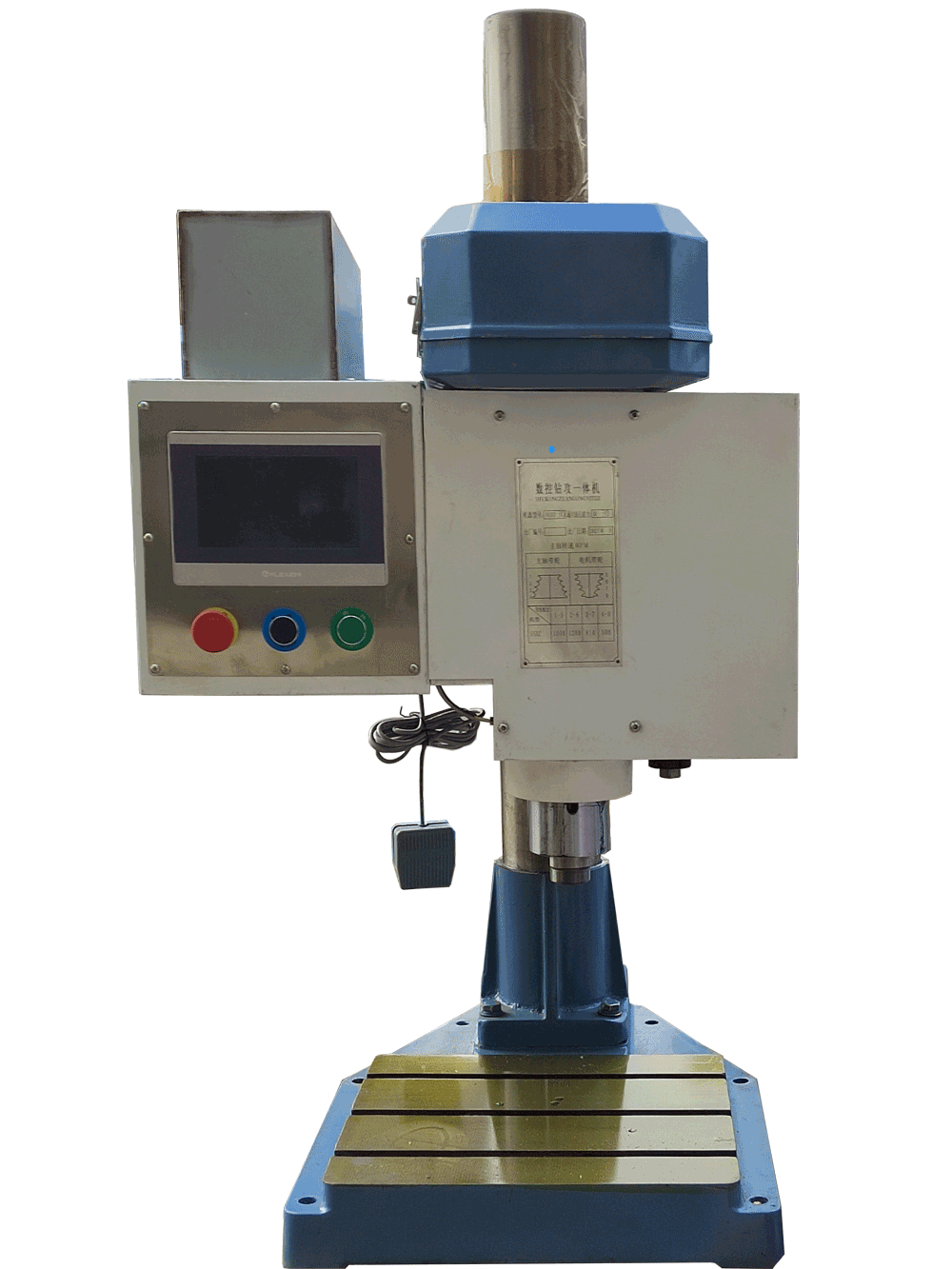

In the fast-paced world of manufacturing, efficiency and precision are key factors in determining success. With advancements in technology, the Automatic Vertical CNC Drilling Tapping Machine has emerged as a game-changer in the industry, revolutionizing the way components are produced. This automated machine combines the capabilities of drilling and tapping operations, offering a seamless solution for manufacturers looking to enhance their productivity.

Gone are the days of manual drilling and tapping processes that were not only time-consuming but also prone to errors. The Automatic Vertical CNC Drilling Tapping Machine operates with precision and speed, thanks to its computer numerical control (CNC) system. This system allows for accurate positioning of the tool, ensuring consistent results with every operation. By automating these processes, manufacturers can significantly reduce the time required to produce components while maintaining high levels of quality.

One of the key advantages of the Automatic Vertical CNC Drilling Tapping Machine is its versatility. This machine is capable of handling a wide range of materials, from metals to composites, making it suitable for various industries. Whether you are producing automotive parts, aerospace components, or electronics, this machine can adapt to your specific requirements, providing flexibility in manufacturing processes.

Moreover, the vertical design of this CNC machine offers additional benefits. By positioning the workpiece vertically, manufacturers can optimize the use of space in their facilities, maximizing productivity. This vertical orientation also facilitates the removal of chips and debris during the drilling and tapping processes, maintaining a clean work environment and preventing potential issues that may arise from chip buildup.

The Automatic Vertical CNC Drilling Tapping Machine is equipped with advanced features that further enhance its performance. With automatic tool changers, coolant systems, and programmable logic controllers (PLCs), this machine operates seamlessly, requiring minimal human intervention. Operators can program the machine to perform complex drilling and tapping sequences, ensuring consistent results and reducing the risk of errors.

In addition to its operational efficiency, the Automatic Vertical CNC Drilling Tapping Machine also contributes to cost savings for manufacturers. By automating repetitive tasks, this machine helps reduce labor costs and improve overall productivity. Furthermore, the precision and accuracy of the drilling and tapping operations result in less material wastage, maximizing the utilization of resources and minimizing production costs.

As manufacturing processes continue to evolve, the demand for automation and precision machining solutions is on the rise. The Automatic Vertical CNC Drilling Tapping Machine represents a significant step forward in meeting these demands, offering a reliable and efficient solution for modern manufacturing facilities. By incorporating this machine into their operations, manufacturers can stay ahead of the competition and meet the growing needs of their customers.

The Automatic Vertical CNC Drilling Tapping Machine is a technological marvel that has the potential to transform the way components are produced in the manufacturing industry. With its automated capabilities, versatility, and cost-saving benefits, this machine is a valuable asset for any manufacturer looking to improve efficiency and productivity. Embracing this advanced technology can lead to enhanced performance, increased profitability, and a competitive edge in today's dynamic market landscape.

Leave a comment