ER collet systems are widely used in machine tools worldwide due to their excellent scalability and precision, serving as daily-use tools. It is crucial to select and install each component correctly, whether you are a senior engineer or a beginner. You may have wondered more than once, "Am I using the right collet chuck?"

Indeed, different sizes and forms of collet chucks can often be confusing. How can you know if you are choosing the collet chuck correctly? Today, let's enlighten you about collet chucks.

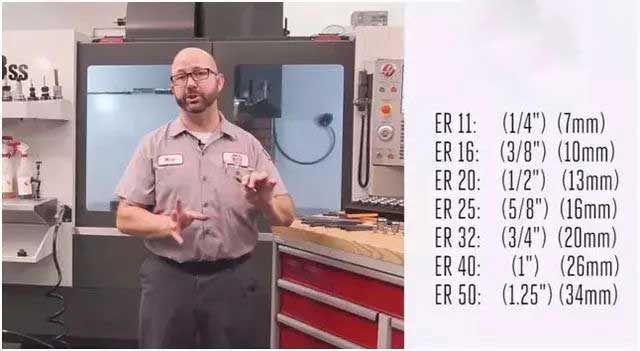

1.How do you determine the size of the ER collet chuck you are using?

We can obtain this by simply measuring the bore of the collet chuck. For example, the measurement in the image shows 32mm, so it is an ER32 collet chuck.

2.Now that we have the tool, how do we select the collet chuck?

Here are the basic types of collet chucks. Choose based on your needs, whether you prioritize high precision or affordability. I chose the second option, which has minimal runout.

3.Can my tool fit in it?

An ER32 collet chuck can accommodate a maximum tool shank size of 20mm. My tool fits perfectly.

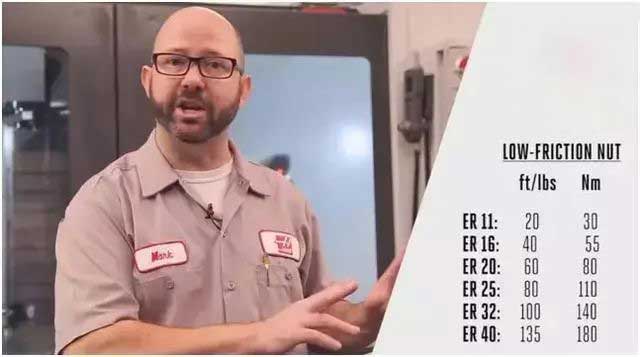

4.What about the collet nut?

I will be performing high-speed dynamic milling, so I selected the second option, a low-friction collet nut. Once everything is prepared, I will start tightening.

5.How do I know the required torque?

Refer to this table. Ah, you can clearly see it's 140Nm.

Leave a comment