29 Feb

Posted by

0 Comment(s)

176 View(s)

Wrenches are commonly used tools for installation and disassembly. They are manual tools that use the leverage principle to turn bolts, screws, nuts, and other threaded fasteners or fixtures with open or socket holes. Wrenches usually have handles at one or both ends to apply external force, enabling the turning of bolts or nuts held by open or socket holes. When used, applying external force along the thread rotation direction on the handle can turn the bolt or nut. What types of wrenches are there? Below are several types of wrenches summarized by the editor. Let's see how many you know.

1.Single-head and double-head wrenches:

Used for fastening or disassembling hexagonal or square-headed nuts and bolts. Single-head wrenches have a single specification, while double-head wrenches have two specifications.

2.Plum wrenches and single-head plum wrenches:

Only suitable for hexagonal nuts and bolts because they are bent, making them particularly suitable for working in narrow positions, concave areas, or places where a regular wrench cannot fit. There are also bent-handle plum wrenches to solve the problem of using in some special environments.

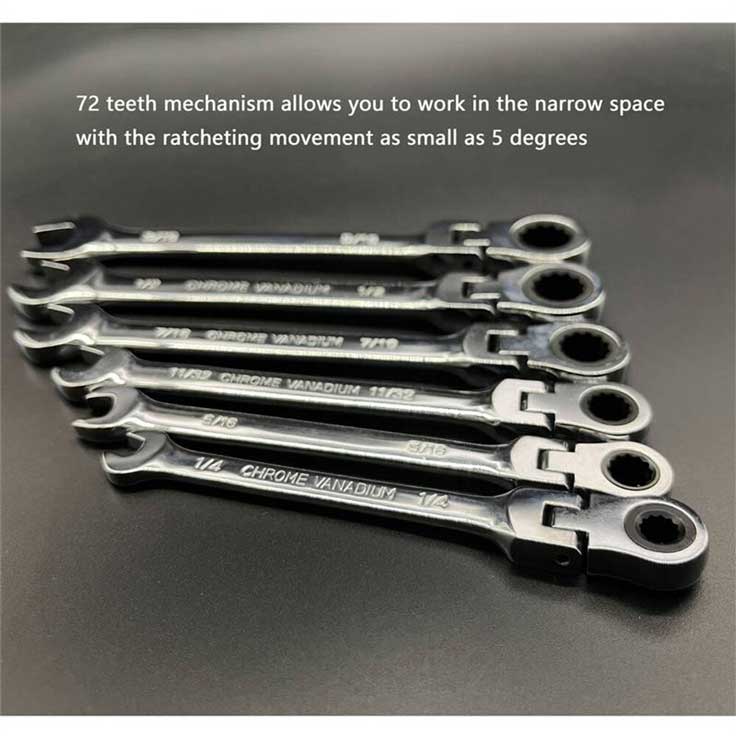

3.Ratchet wrenches:

Ratchet wrenches are manual screw loosening and tightening tools. Single-head and double-head multi-specification adjustable handle ratchet plum wrenches (with fixed holes). They are connected by male and female keys of different sizes through articulated keys. Each plum sleeve has two specifications of plum-shaped through-holes, allowing it to be used for two specifications of screws, thereby expanding the range of use and saving material and labor costs. The adjustable handle can conveniently adjust the angle of use. This type of wrench is used for screw loosening and tightening operations, featuring strong applicability, ease of use, and low cost.

4.Adjustable wrenches:

The opening width can be adjusted within a certain range to turn bolts or nuts of different specifications. Adjustable wrenches, also known as adjustable spanners, have a head and a handle. The head consists of a movable plate lip, fixed plate lip, plate mouth, turbine, and axle pin. Rotating the turbine can adjust the size of the plate mouth.

5.Allen wrenches:

Used for fastening or disassembling internal hexagon screws. Allen wrenches are also called Allen keys. Common English names include "Allen key" (or Allen wrench) and "Hex key" (or Hex wrench). They apply torque to the screw, greatly reducing the user's force intensity and are indispensable tools in the manufacturing industry.

6.Socket wrenches:

Divided into manual and pneumatic, manual socket wrenches are widely used. They are composed of various socket heads, transmission accessories, and connectors, with the function of fastening or disassembling hexagonal head bolts and nuts, especially suitable for narrow spaces or deep concave occasions. The accessories of manual socket wrenches include:

(1) Ratchet wrench.

(2) Sliding bar: The position of the sliding head can be moved to adjust the size of the lever arm.

(3) Universal joint: Similar to a steering handle.

(4) Extension bar: Rotates deeper nuts and bolts.

(5) Socket head: There are six-hole and twelve-hole options.

7.T-type hex wrenches:

In general, there is not just one size of Allen wrench. If a specific size is fixed, it may not meet all needs.

T-type hex wrenches are naturally the same, with various specifications such as 2mm, 2.5mm, 3mm, 4mm, 6mm, 8mm, 10mm, etc., of different sizes.

Leave a comment