Equipment Introduction

Carving machines, based on processing principles, are a combination of drilling and milling.

According to the carving method, they can be divided into two main categories: laser engraving and mechanical engraving.

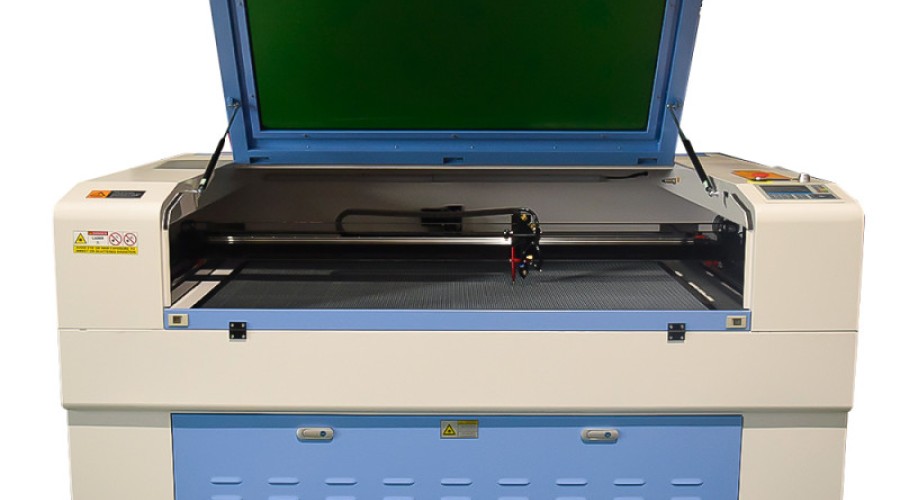

Laser Engraving: Mainly used in the mechanical industry, it utilizes CNC technology with laser as the processing medium. The material undergoes instantaneous melting and gasification under laser engraving, achieving the purpose of processing.

Mechanical Engraving: Also known as CNC engraving machine, mainly used in woodworking, advertising, crafts, and other industries.

Equipment Characteristics

- No contact with the material surface, unaffected by mechanical motion.

- Processing is not affected by the elasticity or flexibility of materials.

- High processing accuracy, fast speed, and wide application fields.

Mechanical Engraving Machine:

- High processing accuracy.

- Runs smoothly, unaffected by the shape of materials.

Processing Accuracy

- Laser Engraving Machine: Processing accuracy is 0.05mm.

- Mechanical Engraving Machine: Processing accuracy is 0.05m.

Processing Materials

Brittle materials such as double-color plates, laminated glass, acrylic, rubber sheets, plastics, cardboard, leather, fabrics, marble, ceramic tiles, etc.

Leave a comment