23 May

Equipment Introduction

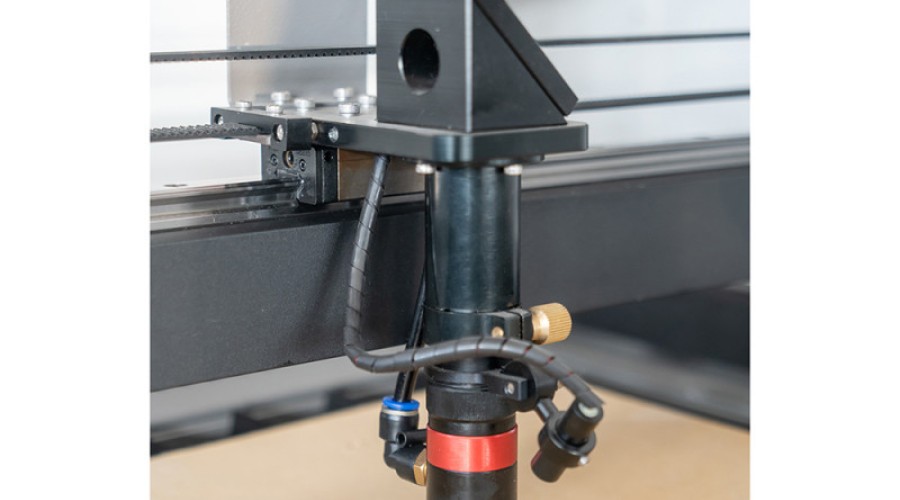

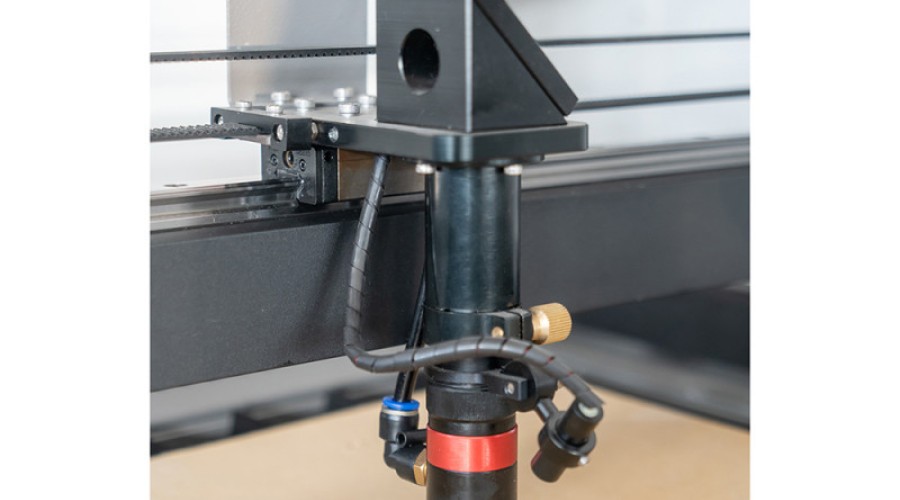

A CNC engraving and milling machine is a type of CNC machine tool that can accurately achieve various processing methods.

Equipment Characteristics

- Uses full closed-loop control technology.

- Has a 0.1μm feed and 1μm cutting capability, with minimal tool wear.

- Utilizes software to simulate the machining process, optimizing process elements and enhancing process safety.

- High dimensional accuracy of machining.

- Strong cutting ability, capable of milling, grinding, drilling, boring, tapping, polishing, and other composite processing capabilities.

- High-gloss machining results similar to a mirror finish, with fast processing speed.

Types of Processing

Curved parts, flat parts, cylindrical parts, irregular parts, complex cavities, etc.

Processing Accuracy

Processing accuracy is 0.002mm, with a surface roughness of Ra < 0.015μm.

Processing Materials

Can process materials such as acrylic, resin, wood, copper, aluminum, titanium alloy, electrodes, hardened steel, carbide, ceramics, etc.

Leave a comment