In the manufacturing industry, efficiency, precision, and consistency are crucial. Tapping machines are one of the key tools for achieving these goals. Widely used in various manufacturing sectors including automotive, aerospace, electronics, and construction, tapping machines play a pivotal role in modern manufacturing processes. Let's explore the practical benefits of using tapping machines in modern manufacturing.

Improved Efficiency:

Tapping machines can complete a large number of tapping tasks in a short amount of time and operate continuously. By automating this repetitive and labor-intensive task, tapping machines significantly enhance efficiency by reducing manual labor and increasing production speed. With faster cycle times and consistent thread quality, manufacturers can optimize their operations and meet tight production schedules more effectively.

Enhanced Precision:

Precision is paramount in manufacturing to ensure products meet precise specifications and quality standards. Tapping machines can precisely control thread dimensions, pitch, depth, and alignment, achieving accurate and uniform threads on each workpiece. This precision eliminates variations common in manual tapping, reducing defects and rework risks. Whether handling small or large projects, manufacturers can rely on tapping machines to consistently deliver precise results.

Ensured Product Quality:

With the precision control systems of tapping machines, each product's thread quality is consistent and accurate. This consistency is critical for ensuring product quality and performance, especially in industries with high precision requirements such as automotive manufacturing and aerospace.

Consistent Thread Quality:

Achieving consistent thread quality is crucial for ensuring the reliability and functionality of assembled components. Tapping machines provide uniform thread profiles and pitches, minimizing differences between individual parts. In industries where seamless fitment is essential, such as automotive engines, hydraulic systems, and electrical equipment production, this consistency is paramount. By maintaining consistent thread quality, tapping machines help improve the overall reliability and performance of products.

Versatility and Adaptability:

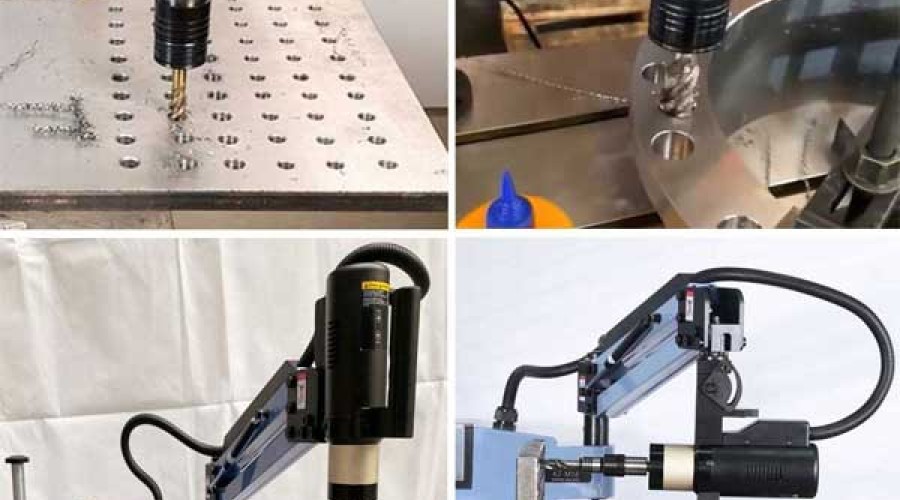

Tapping machines come in various configurations to accommodate different workpiece sizes, materials, and thread specifications. Whether performing through-hole tapping, blind-hole tapping, or multi-spindle tapping, these machines offer versatility and adaptability to meet diverse manufacturing requirements. Additionally, modern tapping machines may feature programmable controls and adjustable settings, allowing operators to easily tailor tapping processes to specific applications. This versatility enables manufacturers to efficiently handle a wide range of projects without the need for multiple specialized machines.

Wide Applicability:

Tapping machines can be applied to workpieces made from various materials and shapes, demonstrating high versatility. Whether it's metal, plastic, or wood, tapping machines can handle them with ease and achieve efficient tapping processes.

Worker Safety and Ergonomics:

Manual tapping operations can pose ergonomic challenges and safety risks for operators, especially when dealing with heavy or irregularly shaped workpieces. Tapping machines alleviate the physical burden on workers by automating the tapping process and reducing direct contact with rotating tools. By promoting a safer working environment and lowering the risk of repetitive strain injuries, tapping machines contribute to creating healthier and more efficient work environments.

In conclusion, tapping machines play a crucial role in modern manufacturing by enhancing efficiency, ensuring product quality, and promoting worker safety. As manufacturing technology continues to advance, the application of tapping machines will become increasingly widespread, offering more development opportunities.

With years of experience in tapping machines, we have developed a wide range of systems. For customizations, please contact us at sales@socoje.com.

Leave a comment