Amateurs see the excitement, while professionals understand the intricacies. When drilling, one must first choose the drill bit, and then consider which drill machine to use.

Twist Drill Bits: The most commonly used drill bits, suitable for drilling wood, plastic, and aluminum. They can be driven by a pistol drill or an impact drill without the impact function.

From top to bottom: 12mm, 10mm, 8mm, 6mm, 4mm, 3mm, 1mm twist drill bits

Impact Drill Bits: These bits can be used for drilling bricks and general partition walls, driven by an impact drill in impact mode. These bits are less commonly used and should never be substituted with twist drill bits, as they will break.

From top to bottom: impact drill bit, twist drill bit, ceramic hole saw, glass drill bit, metal grinding head, wool polishing head, screwdriver bit

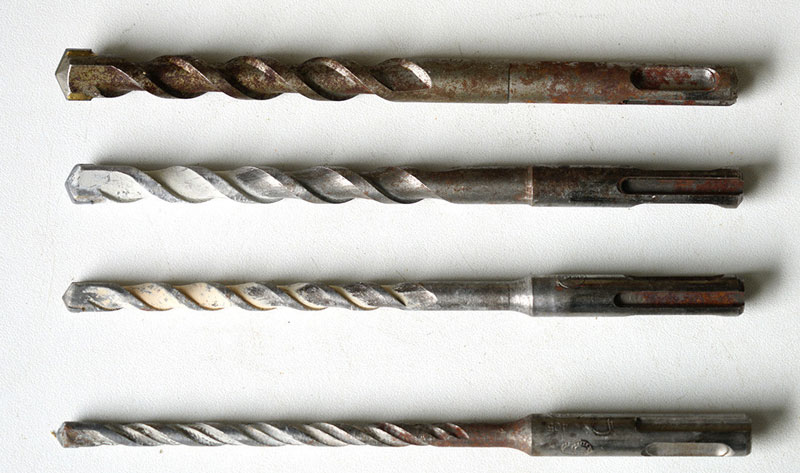

Four-slot Hammer Drill Bits: Used for drilling brick, partition walls, load-bearing concrete walls, and ceilings. Driven by a rotary hammer drill in impact rotation mode, these are commonly used in households and by installation professionals.

From top to bottom: 12mm, 10mm, 8mm, 6mm four-slot hammer drill bits

Glass Drill Bits: Used for drilling small holes in non-tempered glass, ceramics, and tiles, generally with a diameter below 8mm. Driven by a pistol drill or an impact drill without the impact function.

Tile Hole Saws: Used for drilling larger holes in glass, ceramics, and tiles, generally with a diameter of 8mm and above. Driven by a pistol drill or an impact drill without the impact function.

Thin Plate Hole Saws: Used for drilling holes in plastic, very thin iron sheets, and aluminum sheets, such as holes for installing backup sensors. Driven by a pistol drill or an impact drill without the impact function.

Woodworking Hole Saws: Used for drilling holes in wood, including solid wood furniture panels and gypsum board ceilings. Driven by a pistol drill or an impact drill without the impact function.

Metal Hole Saws: Used for drilling holes in hard metal plates, such as kitchen sinks and balcony enclosures. Driven by a pistol drill or an impact drill without the impact function.

From left to right: woodworking hole saw, metal hole saw, thin plate hole saw

In addition, there are many other unusual drill bits and grinding heads. If you can imagine it, you can find it.

Typical Operation Methods for Some Scenarios

Installing Screws on Furniture Surface: For tasks like attaching a hook rack on a wooden door or a handle on a cabinet door, usually, an electric screwdriver with self-tapping screws can be used directly. I typically drill a 1mm pilot hole with a twist drill first, making the screwing process smoother.

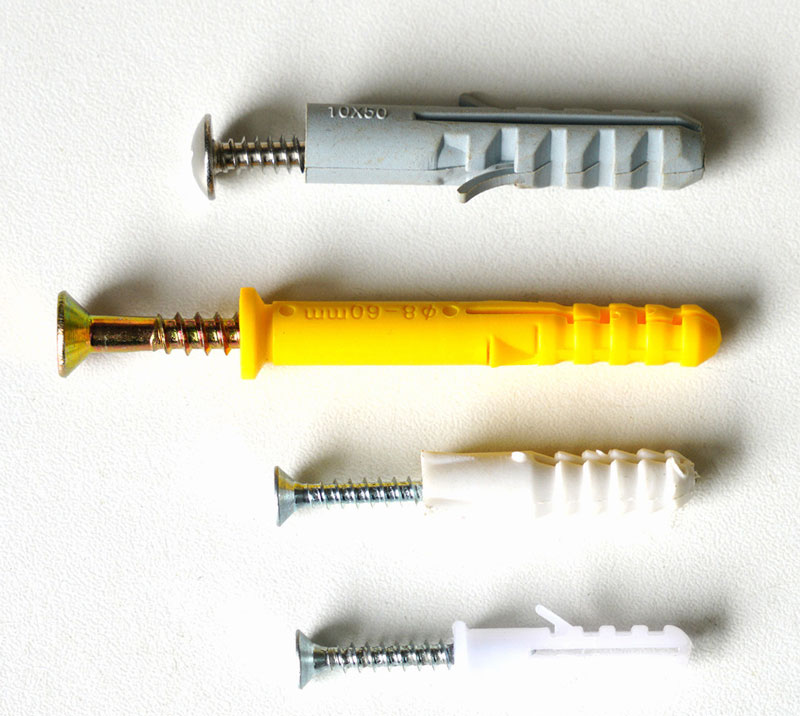

Installing Plastic Expansion Bolts: Select a hammer drill bit with the same diameter as the expansion bolt. The depth of the drill hole depends on how deep the screw needs to be inserted. It's best to drill deep enough in one go. The weight-bearing capacity of such expansion bolts depends on the bolt diameter, depth, screw compatibility, wall material and structure, and the mechanical properties of the hanging object. Ensure thorough consideration before drilling.

Three diameters and four lengths of plastic expansion bolts

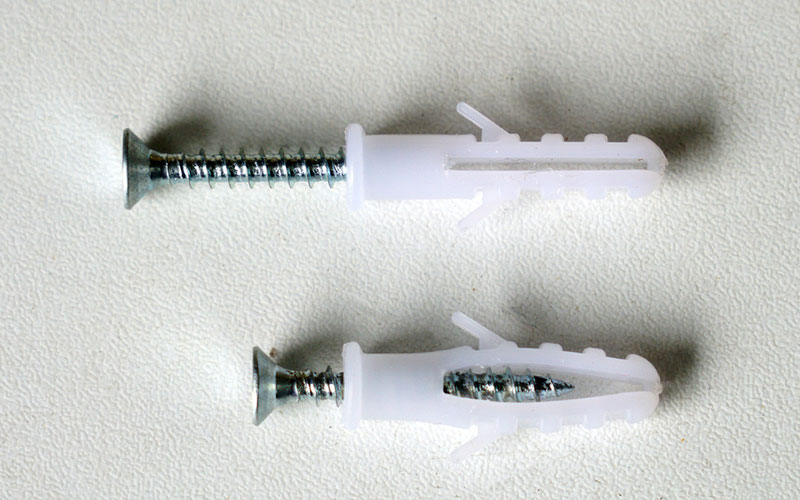

Unexpanded and expanded plastic expansion bolts

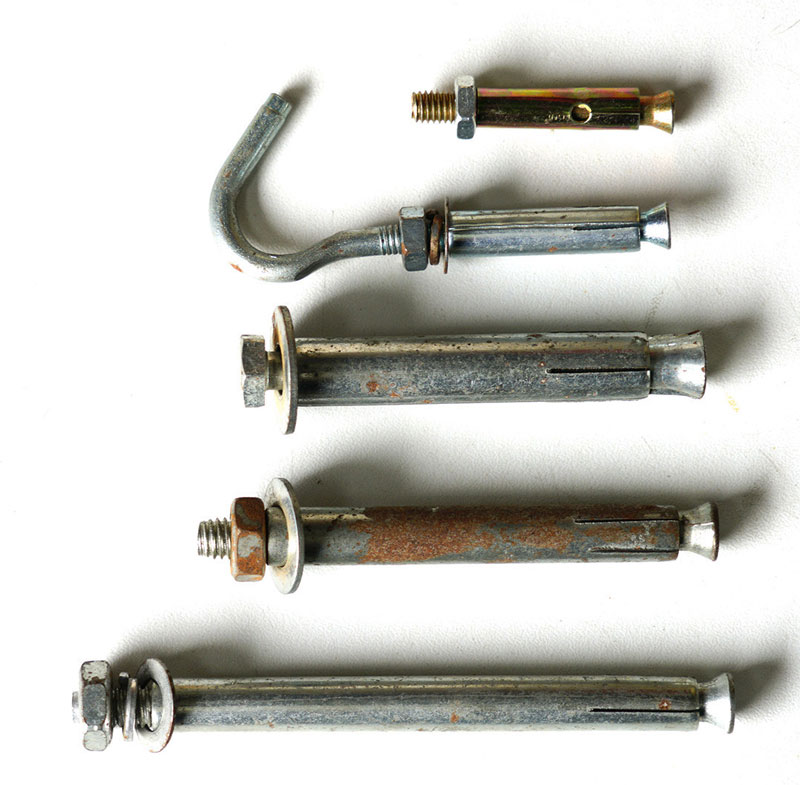

Metal expansion bolts of different diameters and lengths

Walls with Tiles: For tasks like installing racks or rods in the kitchen or bathroom, first, use a glass drill bit or ceramic hole saw to drill through the tile, then switch to a hammer drill.

Walls with Glazed Tiles: This is a tricky one. Prepare yourself mentally and have enough ceramic hole saws or glass drill bits, assuming one drill bit for every three holes. Lay down newspaper or plastic bags to catch the slurry, and have someone assist you with water cooling. It's recommended to use a ceramic hole saw. Estimate the position, hold the drill at an angle, and grind a crescent-shaped groove on the tile, spraying a little water inside the groove. Gradually deepen the groove. Once you create a circular groove, the drill bit will stabilize. Increase the drilling power while keeping the water cooling continuous to prevent the bit from overheating. Continue until the slurry color changes from the gray-white of the tile base to the gray-black of the cement, indicating that the tile has been penetrated. Then switch to a hammer drill to reach the desired depth. Finally, clean up the mess.

Drilling Cable Pass-Through Holes in Desktops: Choose a woodworking hole saw that matches the size of the cable grommet cover. It's better to avoid sets with multiple sizes, as they often don't fit well. Opt for individually packaged fixed sizes. Typically, a cable grommet cover has a diameter of about 50mm, suitable for almost all electrical device plugs. For smaller sizes, 35mm can be used, though larger plugs like VGA or DVI connectors might not fit through, but computer power cords can. If the desktop is thick and the hole saw depth is insufficient, drill from the other side. Additionally, if you have a smoke alarm at home, either shield it or drill carefully—trust me on this.

Wall Drilling Precautions: Electrical wires might run vertically above or below distribution boxes and sockets or between closely spaced sockets. Water pipes might be located directly below angle valves, showers, and faucets. If you have blueprints or photos of hidden projects from the renovation, it's best to double-check these before drilling.

Leave a comment