An electric drill is a power-driven drilling tool. It is a common product among power tools and has the highest demand. Annually, electric drills account for 35% of China's power tool production and sales.

Working Principle

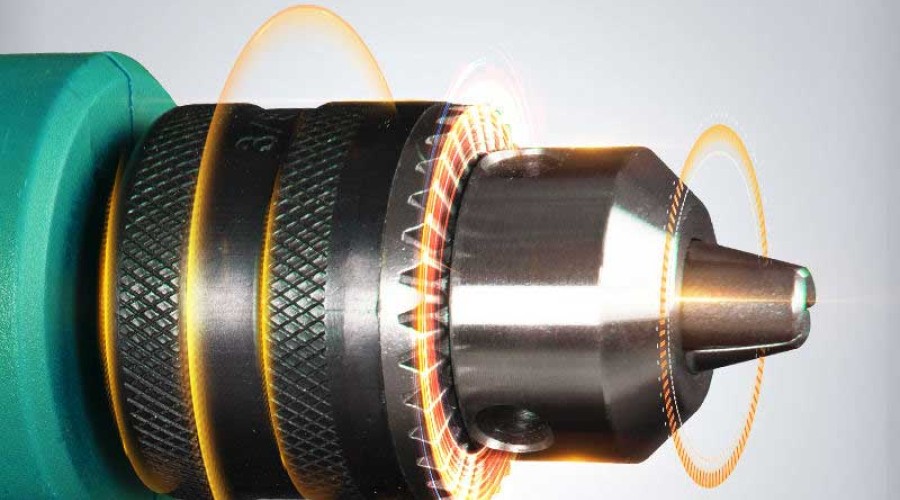

The drill operates using an electromagnetic rotary or reciprocating small-capacity motor. The rotor cuts the magnetic field to function, driving the operational device through the transmission mechanism, which then increases the drill bit's power through gears. This allows the drill bit to scrape the surface of objects and penetrate them more effectively.

Personal Protection When Using an Electric Drill

- Wear a protective face shield and safety glasses when working face-up.

- Ensure the drill bit holder is properly installed.

- Be aware that the drill bit gets hot during operation and can burn the skin.

- When using a handheld drill with a bit diameter over Φ12mm, use a side-handle pistol drill.

- Take fall protection measures when working on a ladder or at heights, and ensure the ladder is supported by ground personnel.

Precautions Before Operation

- Verify that the power supply's capacity is adequate, the cable is properly installed, and a leakage protection device is in place. Take steps to prevent cable damage.

- Ensure the drill bit is securely installed.

- Check the switch on the drill to confirm the lock-on button's status, as it may pose a safety risk if not properly set.

Commonly Overlooked Operating Methods

- When drilling into metal, use a center punch at the drilling spot first.

- For large holes, pre-drill with a small bit before using a larger bit to expand the hole.

- For prolonged drilling in metal, use cooling methods to keep the bit sharp.

- Do not clean drill shavings with your hands directly.

Simple Maintenance and Inspection

- Check the Drill Bit: Using a dull or bent bit can overload the motor and reduce efficiency. Replace or repair immediately if needed.

- Check Fastening Screws: Inspect the drill body’s fastening screws before use. Tighten any loose screws immediately.

- Check Carbon Brushes: Carbon brushes in the motor are consumable items. Replace them immediately if they are worn beyond limits, and always keep them clean.

- Check the Grounding Wire: The grounding wire is crucial for safety. Regularly check that the casing of Class I tools (metal casings) is properly grounded.

Leave a comment