ER spring collets belong to the category of spring collets. Although they are auxiliary devices used to secure workpieces, they still play a certain role in the operation of machine tools. These collets possess a certain elasticity, which allows them to provide a buffering effect during equipment operation. Common types of collets in daily life include spring collets and clamp collets. Despite their small size, spring collets are powerful. They can accurately position the tools that need to be clamped, withstand a certain amount of force, and increase the driving force of the machinery. They can quickly clamp and release components in the working state. Despite operating at high speeds, they do not cause energy loss. Factors affecting clamping force may exist during use. Clamping force refers to the force exerted by the collet on the working parts, and it is a simple structural device.

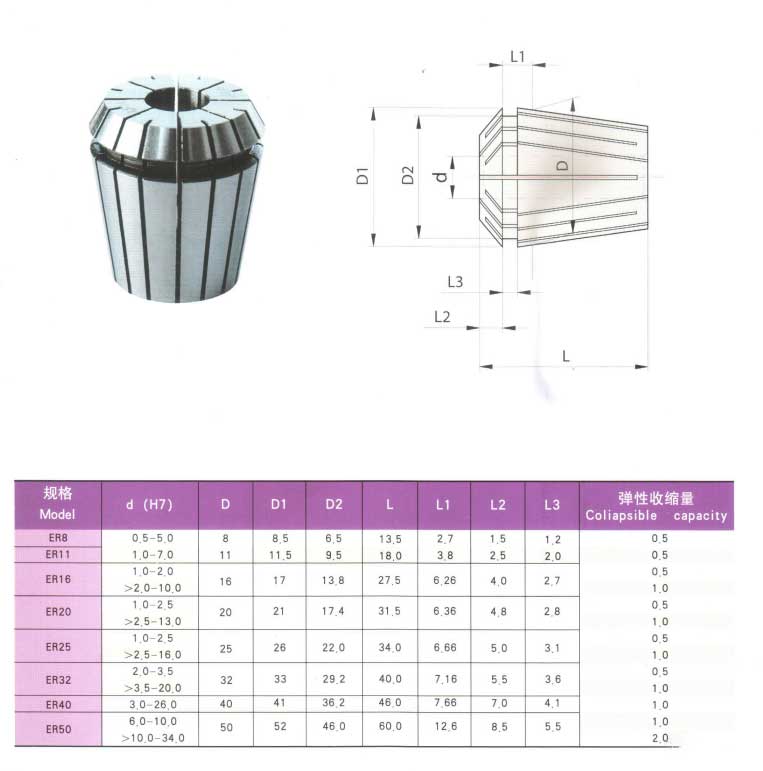

The accuracy standards of ER collets are generally as follows:

Level 1: Accuracy: 0.01mm. ER collets made of bearing steel have high elasticity and service life. All ER spring collets are precision ground and manufactured in accordance with German DIN 6499 accuracy specifications, with 1mm of elastic expansion space.

Level 2: Accuracy: 0.01 - 0.015mm. ER spring collets made of bearing steel have high elasticity and service life. All ER spring collets are precision ground and manufactured in accordance with German DIN 6499 accuracy specifications, with 1mm of elastic expansion space. ER collets use the elastic deformation of a spring collet in the middle to clamp the tool, which is relatively simple and convenient and does not require high precision for the tool shank.

ER collets are a type of collet used to connect the shank and CNC tool. ER collets, commonly known as spring collets, are drill chucks installed on the main spindle of machine tools, and their function is to lock the tool and spindle. The advantages of ER collets are as follows: firstly, they improve the quality of part accuracy and surface roughness; secondly, they can prolong the tool life and reduce vibration; thirdly, they can reduce tool inventory.

In modern complex manufacturing environments, most factories undergo rigorous training and serious study of the processing and motion principles, architecture features, and usage skills of new equipment. Only in this way can they be conveniently operated. This is especially true for some higher-end technical systems. For example, many machine tools use collets, which have elasticity and are therefore also called spring collets. They are fixtures used to fix some parts. They can be divided into many types, such as pneumatic collets, common spring collets, clamp collets, etc. Although they are small, they play a significant role in mechanical motion. For example, the valve spring inside the machine and the control spring in the automobile clutch can control mechanical motion. In addition, there are buffer springs, which exist inside devices that produce forces due to motion. Their function is to absorb the energy generated by vibration and impact. Clock springs in some delicate mechanical items can store and convert output energy into power. Nowadays, it is also a mechanical era, and various mechanical processing and manufacturing methods are becoming more novel and effective, breaking away from the original limitations.

Leave a comment