3 hp (2.2 kW) Air Compressor Motor 208-230V 7/8 Shaft

from

$485.38

Ex Tax: $485.38

- Stock: In Stock

- Model: SCJ009590

- SKU: SCJ009590

Products Sold: 0

Product Views: 345

Ask a Question About This Product

- Description

3 hp (2.2 kW) Air Compressor Motor 208-230V 7/8 Shaft

Brief

SOCOJE single-phase air compressor motor has economical price and strong running performance. It runs at 3 HP (2.2 kW) output power, 3600 rpm speed and 208-230 volts. The current is 16-15 A, the shaft length is 2.25 and the shaft diameter is 7/8. it is a double capacitance ac electric motor with the protect grade of 23 IP.

Description

3 hp air compressor motor is equipped with a protector and 7/8 shaft, and can be used in water pump industry, fan industry, refrigerator, medical equipment, etc. Lower price but better quality.

Specification

| Model | SCJ009590 |

| Power | 3 HP (2.2 kW) |

| Speed | 3600 rpm |

| Current | 16-15 A |

| Voltage | 208-230 V |

| Protector | √ |

| Frame | 143/ 5T |

| Shaft diameter | 7/8 |

| Shaft length | 2.25 |

| Capacitance | 2 |

| ENC | ODP |

| Frequency | 60Hz |

| IP | 23 |

| INS | F |

| ROT | CCW |

| Housing material | Steel plate |

| Packing size | 38*27*27cm |

| Weight | 23kg |

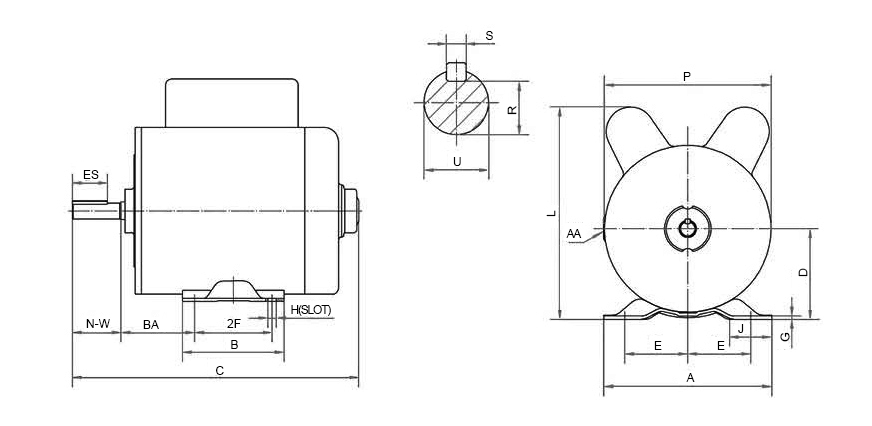

Dimention (Unit: inch)

Details

Tips: Maintenance of air compressor motor

- After the air compressor motor has been running for a long time, pay attention to how long it takes to add oil and which parts need to be replaced and maintained. Master detailed knowledge and implement it regularly. The specific time interval is usually combined with the actual work situation. When the air compressor motor fails, measures should be taken to avoid more trouble due to misoperation.

- Clean the air compressor regularly. Whether it is the internal parts of the air compressor system, or the air compressor motor and the surface of the equipment, it is required to be free of dirt and dust, so it is necessary to strengthen the cleaning effort. Too much dirt not only reduces the gas quality, but also causes high temperatures. It is necessary to add new oil and determine when the oil needs to be changed according to the use environment. Due to long-term use, the composition of the oil is constantly decreasing and changing, and it is difficult to meet the requirements of the air compressor motor.

- Regularly adopt professional methods to detect whether the air compressor wiring is loose or aging, and record the situation of each part in detail, which is very beneficial to the maintenance of the air compressor motor. It is convenient to troubleshoot if there is a fault. The implementation of the air compressor motor maintenance method is very important, it determines the later operation efficiency and whether it can be adjusted to a good state.

Because the air compressor motor has the characteristics of compact structure, high efficiency, energy saving, and excellent starting performance, it is widely used in the field of compressors, involving plateaus, ships, outdoors and hot and humid areas, so we must pay attention to maintenance in daily life.

- Reviews