7.5 hp (5.6 kW) Air Compressor Motor 208-230V 1-1/8 Shaft

from

$934.15

Ex Tax: $934.15

- Stock: In Stock

- Model: SCJ009592

- SKU: SCJ009592

Products Sold: 0

Product Views: 330

Ask a Question About This Product

- Description

7.5 hp (5.6 kW) Air Compressor Motor 208-230V 1-1/8 Shaft

Brief

7.5hp air compressor motor is single-phase motor with 208-230V output voltage, 33-30A current and 3600 rpm output speed. The shaft diameter is 1-1/8 inch and the shaft length is 2.75 inch. Double capacitance design, IP 23, 182/ 4T frame.

Description

5.6kW electric motor for air compressor has competitive price. The motor shell is made of durable metal material, sturdy and reliable, with a smooth surface and comfortable to use.

Specification

| Model | SCJ009592 |

| Power | 7.5 HP (5.6 kW) |

| Speed | 3600 rpm |

| Current | 33-30 A |

| Voltage | 208-230 V |

| Protector | × |

| Frame | 182/ 4T |

| Shaft diameter | 1-1/8 |

| Shaft length | 2.75 |

| Capacitance | 2 |

| ENC | ODP |

| Frequency | 60Hz |

| IP | 23 |

| INS | F |

| ROT | CW/ CCW |

| Housing material | Steel plate |

| Packing size | 48*37*40cm |

| Weight | 43kg |

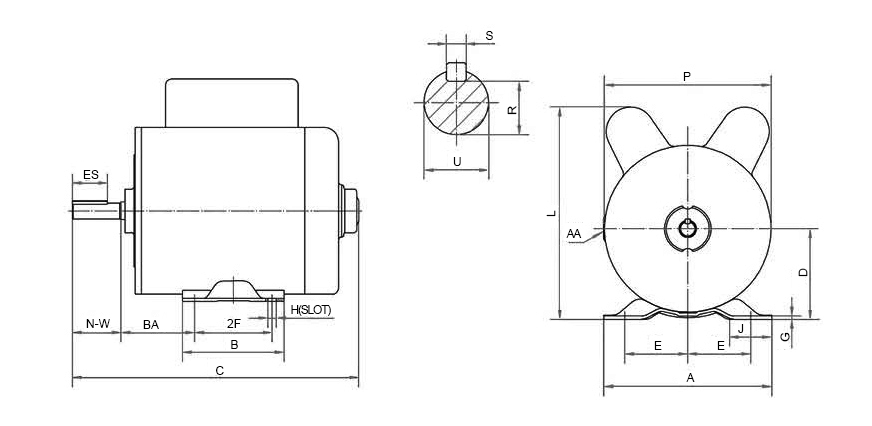

Dimention (Unit: inch)

Details

Tips: Difference between high voltage air compressor motor and low voltage air compressor motor

Both the high-voltage air compressor motor and the low-voltage air compressor motor have their own advantages and disadvantages.

Compared with low-voltage air compressor motors, high-voltage air compressor motors have the following advantages:

- The motor power of the air compressor can be increased, up to several kilowatts, or even tens of thousands of watts. This is because, when outputting the same power, the current of the high-voltage air compressor motor can be much smaller than that of the low-voltage air compressor motor. Therefore, the stator copper loss of a high-voltage motor will be smaller than that of a low-voltage motor. For a larger power air compressor electric motor, when using low-voltage electricity, because of the need for a thicker wire and a larger area of the stator slot, the diameter of the stator core will also be large, and the volume of the entire motor will also become very big.

- For the larger capacity air compressor motor, the power supply and power distribution equipment used by the high-voltage air compressor motor is less than the overall investment of the low-voltage air compressor motor, and the line loss is small, which can save power consumption.

Compared with low-voltage air compressor motors, the disadvantages of high-voltage air compressor motors are:

- The cost of winding is relatively high, and the cost of related insulation materials will also increase accordingly.

- The requirements for the operating environment are far higher than the requirements for the low-voltage electric motors for air compressors.

- The insulation treatment process is difficult, the man-hour cost is high, and the air compressor motor manufacturing cycle is long.

- Reviews