- Stock: In Stock

- Model: SCJ009682

- SKU: SCJ009682

Available Options

Ask a Question About This Product

- Description

Double Rod Cylinder 40mm Bore 300mm Stroke Double Acting

Brief

Description

Double-acting dual rod cylinders with customized bore and stroke (max. stroke length up to 300mm) have good resistance to bending and twisting moments. Speed range is between 30 and 500mm/s. They are kindly designed with a bumper which can relieve the impact so as to minimize the potential damage caused by external force.

Product features:

- There are magnetic switch slots around the cylinder body convenient to install inductive switches.

- Embedded installation and fixation mode saves the installation space.

- It has good resistance to bending and twisting moments, and it can withstand a certain level of side load.

- Mounting holes on three sides facilitates multi-position mounting.

- Bumper in front of the barrel can adjust the stroke of cylinder and relieve impact.

- Standard configuration of this series has magnet and the type without magnet is not available.

Specifications:

| Model | SCJ009682 | |||||

| Bore size | 10mm | 16mm | 20mm | 25mm | 32mm | |

| Acting type | Double acting | |||||

| Fluid | Air (to be filtered by 40 um filter element) | |||||

| Operating pressure | 0.15~1.0MPa (22~145psi) | |||||

| Proof pressure | 1.5MPa (215psi) | |||||

| Temperature | -20~70℃ | |||||

| Speed range | 30~500mm/s | |||||

| Adjustable stroke | -10~0mm | |||||

| Stroke tolerance | Stroke≤100+1.00 Stroke>100+1.50 | |||||

| Cushion type | Bumper | |||||

| Non-rotating tolerance (Retract position) | ±0.4° | ±0.3° | ||||

| Port size | M5 × 0.8 | 1/8″ | ||||

| Weight | 1Kg 2Kg 3Kg 4Kg 5Kg | |||||

Stroke:

| Bore size | Standard stroke | Max. std stroke |

| 10mm | 10 20 30 40 50 60 70 80 90 100mm | 100mm |

| 16mm | 10 20 30 40 50 60 70 80 90 100 125 150 175 200mm | 200mm |

| 20mm | 10 20 30 40 50 60 70 80 90 100 125 150 175 200mm | 200mm |

| 25mm | 10 20 30 40 50 60 70 80 90 100 125 150 175 200mm | 200mm |

| 32mm | 10 20 30 40 50 60 70 80 90 100 125 150 175 200mm | 200mm |

| Note: When the stroke less than or equal to 100mm, the dimensions of non-std stroke cylinder has the same dimensions as the next longer stroke std. stroke cylinder, e.g. 35mm stroke cylinder has the same dimensions of 40 std. stroke cylinder. | ||

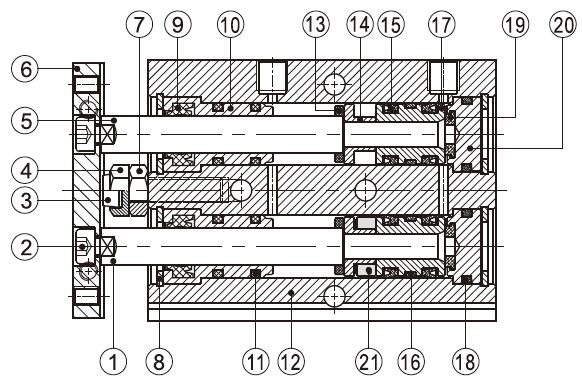

Inner structure and material of major parts:

| NO. | Item | Material | |

| 1 | Piston rod B | Φ32 | S45C |

| Other | SUS303 | ||

| 2 | Screw | Carbon steel | |

| 3 | Bumper | POM | |

| 4 | Adjustable nut | Carbon steel | |

| 5 | Piston rod A | S45C | |

| 6 | Fixing plate | Free cutting steel | |

| 7 | Screw | Carbon steel | |

| 8 | C clip | Spring steel | |

| 9 | Wiper seal | NBR | |

| 10 | Front cover | Aluminum alloy | |

| 11 | O-ring | NBR | |

| 12 | Body | Aluminum alloy | |

| 13 | Bumper | TPU | |

| 14 | Magnet holder | Φ10 | SUS303 |

| Other | Aluminum alloy | ||

| 15 | Piston seal | NBR | |

| 16 | Wear ring | Wear resistant material | |

| 17 | Piston | Φ10 | SUS303 |

| Other | Aluminum alloy | ||

| 18 | Seal ring | NBR | |

| 19 | Bumper | TPU | |

| 20 | Back cover | Aluminum alloy | |

| 21 | Magnet | Sintered metal (Neodymium-iron -boron) | |

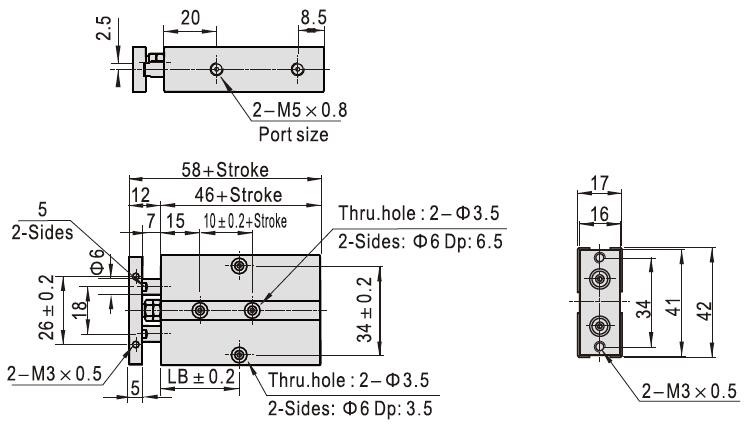

Dimensions (unit:mm):

TN10

| Item/Stroke | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

| LB | 30 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 |

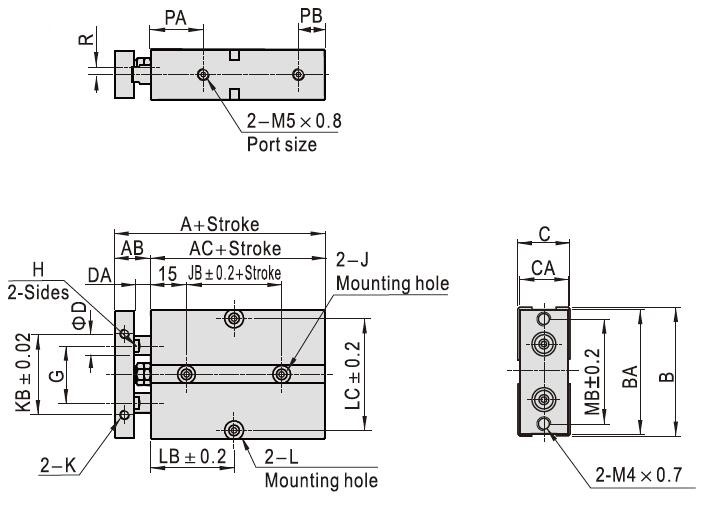

TN16~25

| Bore size/Item | A | AB | AC | B | BA | C | CA | D | DA | G | H | J |

| 16 | 68 | 15 | 53 | 54 | 53 | 21 | 20 | 8 | 7 | 24 | 6 | Both sides: Φ7.5Dp:7.5Thru.hole:Φ4.5 |

| 20 | 78 | 20 | 58 | 62 | 61 | 25 | 24 | 10 | 10 | 28 | 8 | Both sides: Φ7.5Dp:7.5Thru.hole:Φ4.5 |

| 25 | 81 | 19 | 62 | 73 | 72 | 30 | 29 | 12 | 9 | 34 | 10 | Both sides: Φ7.5Dp:7.5Thru.hole:Φ4.5 |

| Bore size/Item | JB | K | KB | PA | PB | L | LC | MB | R |

| 16 | 20 | M4×0.7Dp:5 | 34 | 22 | 11 | Both sides: Φ8Dp:4.5Thru.hole:Φ4.5 | 47 | 47 | 3 |

| 20 | 20 | M4×0.7Dp:5 | 44 | 25 | 12 | Both sides: Φ8Dp:4.5Thru.hole:Φ4.5 | 55 | 55 | 3.5 |

| 25 | 30 | M4×0.7Dp:6 | 56 | 27 | 12 | Both sides: Φ8Dp:4.5Thru.hole:Φ4.5 | 66 | 66 | 6 |

| Bore size/Item | LB | |||||||||||||

| Stroke ≤ | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 |

| 16 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 87.5 | 100 | 112.5 | 125 |

| 20 | 35 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 87.5 | 100 | 112.5 | 125 |

| 25 | 40 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 92.5 | 105 | 117.5 | 130 |

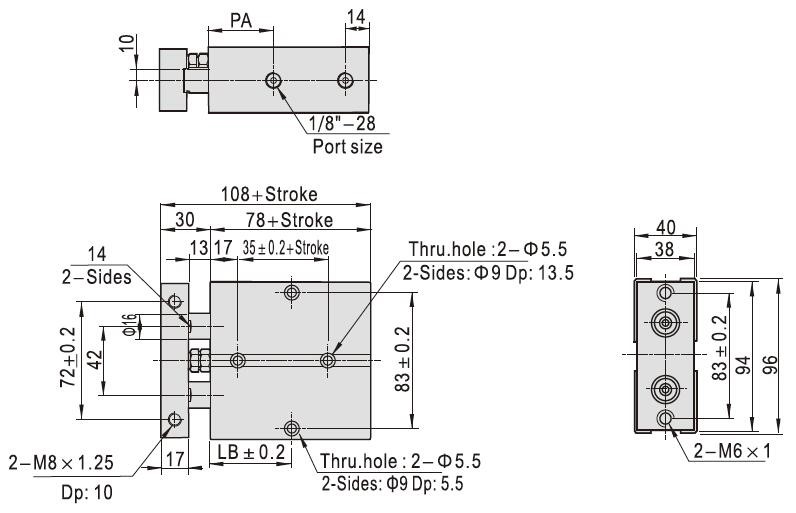

TN32

| Item/Stroke | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 |

| LB | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 102.5 | 115 | 127.5 | 140 |

| PA | 35 | 40 | ||||||||||||

Note: As the precision of the manufacture and guide is high, please do not dismantle the fixed block or cylinder cover.

Likewise, the stroke length of dual rod cylinders are customizable with additional costs and the function of high temperature resistance is optional.

| Bore size Extra rates | 10mm | 16mm | 20mm | 25mm | 32mm | 40mm |

| Stroke length plus 50mm | $1.23 | $1.54 | $1.85 | $2.46 | $3.08 | $9.54 |

| High temperature resistance | $1.85 | $2.15 | $2.77 | $2.92 | $3.85 | $4.92 |

Tips: Brief introduction about dual rod cylinders

The double rod cylinder is a cylindrical metal machine part that drives the piston to reciprocate in the cylinder. Air in the engine cylinder converts thermal energy into mechanical energy through expansion, and the gas is compressed by the piston in the compressor cylinder to increase the pressure. The casing of turbines and rotary piston engines usually belongs to cylinder. Applications of air cylinders are commonly found in printing (used for tension control), semiconductors (such as welding machine and chip grinding), automation control, robots and many others. Double acting cylinders work by supplying air alternately from both ends of the piston, producing force in one or two directions.

- Reviews