- Stock: In Stock

- Model: SCJ009477

- SKU: SCJ009477

Available Options

Ask a Question About This Product

- Description

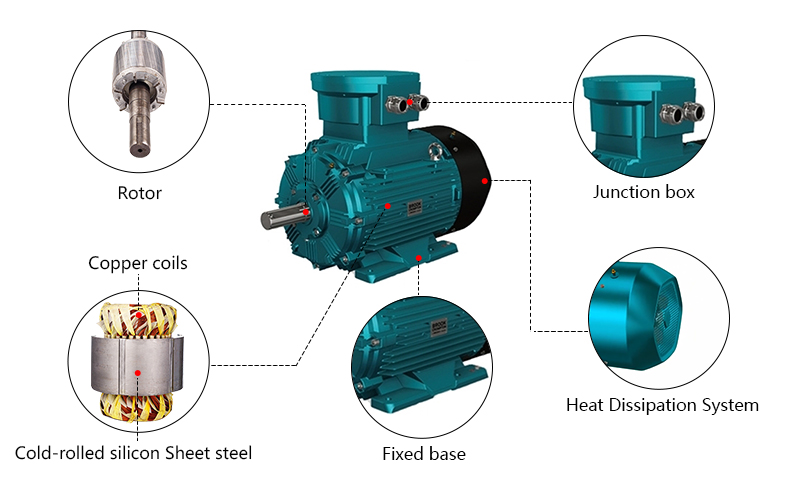

Explosion Proof Motor, 380V, 2P/ 3P/ 4P, 15hp (11kW)

Brief

Description

Three phase asynchronous motor with rated viltage 380V, -20℃~40℃ ambient temperature, "Δ" connection.This type of induction motor offers high efficiency and energy saving, safety, reliability and convenient maintenance.

Specification

| Model | WEX3-160M1 |

| Numbers of poles | 2P/ 4P/ 6P |

| Synchronous speed | 3000r/min/ 1500r/min/ 1000r/min |

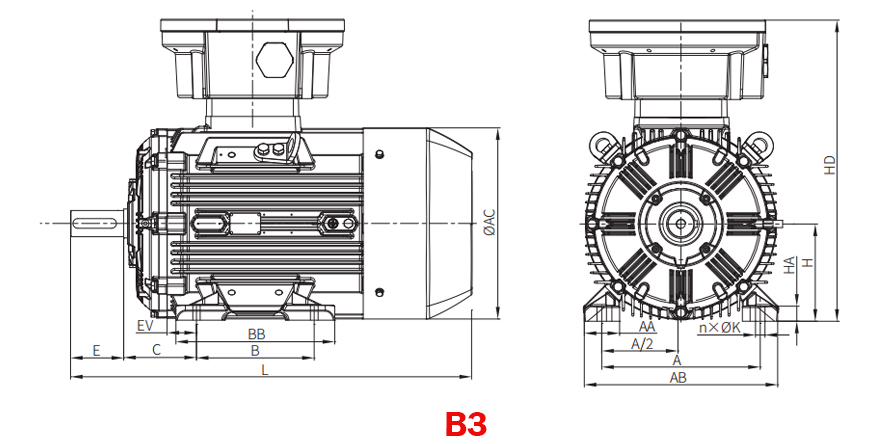

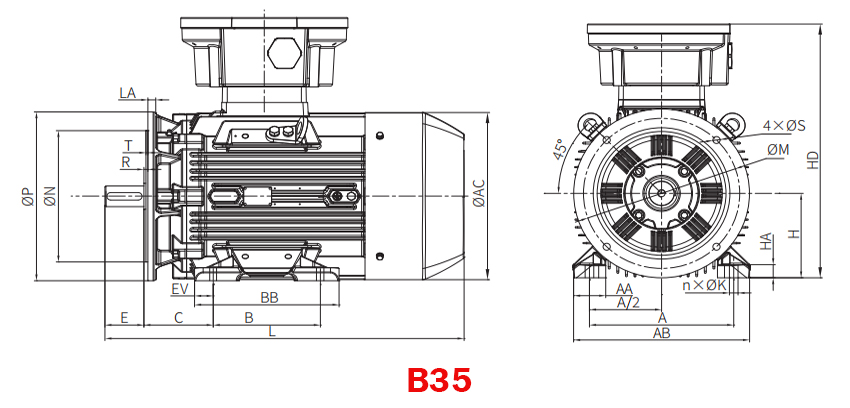

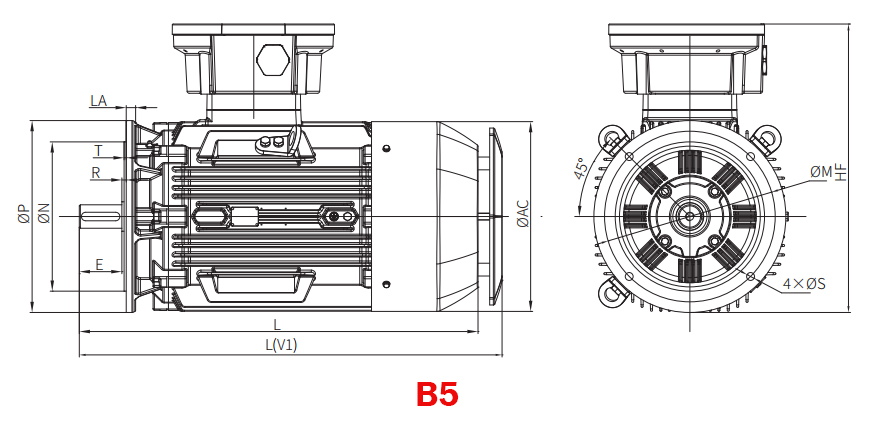

| Mounting types | B3/ B5/ B35 |

| Rated power | 15hp (11kW) |

| Rated voltage | 380V (380V-660V can be customized) |

| Frequency | 50Hz |

| Duty | S1 |

| Ambient temperature | -20℃~40℃ |

| Altitude | ≤1000m |

| Humidity | ≤90% |

| Terminal box position | Top |

| Type of cable entry | Cable grand |

| Enclosure | IP55 |

| Inverter operation | Inverter use ready up to 500V acc |

| Insulation | Class F |

| Cooling type | IC411 |

| Shaft key | Type A |

| Lubrication | Sealed |

| Connectiom | "Y" connection |

| Fan material | Engineered plastic |

| Rotation direction | Clockwise rotation at drive end |

| Winding temperature measurement | Thermistors (PTC) |

| Anti-corrosion grade | C3 |

| Certificates | IEC, EX, ATEX |

| Explosion-proof mark | Ex d I Mb, Ex d ⅡB T4 Gb, Ex d ⅡC T4 Gb |

| Warranty | 12 months |

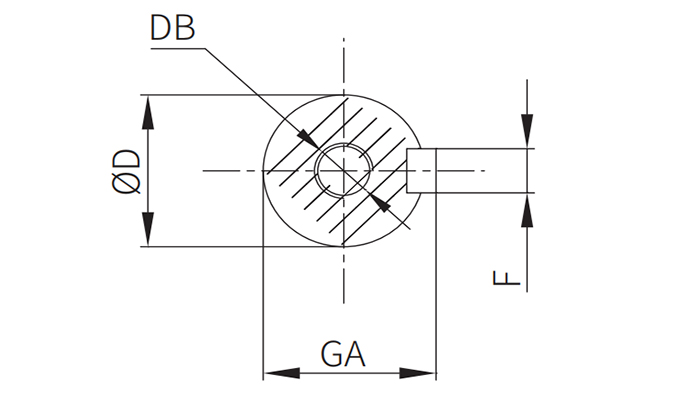

Dimensions (mm)

| Mounting type | Frame size | Mounting dimensions(mm) | Outline dimensions (mm) | ||||||||||||||||||||||||||

| A | A/2 | B | C | H | n | K | M | N | P | R | S | T | AA | EV | LA | AB | BB | HA | AC | HD | L | ||||||||

| Ex db eb | Ex db | ||||||||||||||||||||||||||||

| B3 | 160M | 254 | 127 | 210 | 108 | 160 | 4 | 14.5 | - | - | - | - | - | - | 65 | 60 | 22 | 23 | 341 | 310 | 320 | 256 | 20 | 25 | 315 | 450 | 455 | 668 | |

| B35 | 254 | 127 | 210 | 108 | 160 | 4 | 14.5 | 300 | 250 | 350 | 0 | 18.5 | 5 | 65 | 60 | 22 | 23 | 16 | 341 | 310 | 320 | 256 | 20 | 25 | 315 | 450 | 455 | 668 | |

| B5 | - | - | - | - | 160 | - | - | 300 | 250 | 350 | 0 | 18.5 | 5 | - | - | - | - | 16 | - | - | - | - | - | - | 315 | 465 | 470 | 670 | |

| Frame size | Shaft (mm) | ||||

| D | E | F | GA | DB | |

| 160M | 42 | 110 | 12 | 45 | M12*28 |

Details

Tips: How to maintain Explosion Proof Motor?

1. The brush and slip ring surface should match. There should be a gap of 0.1-0.2mm between the brush and the brush holder, and the distance between the lower edge of each brush holder and the slip ring should be 2-3mm. The pressure of the brush on the slip ring should be adjusted to the lowest pressure where no spark occurs, generally 0.02-0.03MPa, and the pressure of each brush should not differ by 10%. The brush holder and the cross bar should be fastened, and there should be no dirt or damage between the insulating liner, insulating pad and slip ring. The insulation resistance of the brush holder should be above 100MΩ.

2. Partially or completely replace the coil or the damp motor should be dried. For the motor that has not been used for a long time, use a shaker to measure the insulation resistance, and then judge whether the motor needs to be dried based on the measurement result.

3. After the motor is disassembled, remove the bearing and wash it with kerosene or gasoline. When the measured bearing clearance exceeds the allowable value, the rolling bearing should be replaced.

4. When overhauling the cooling system, the temperature measurement, fan blades and other auxiliary devices must be checked at the same time.

- Reviews