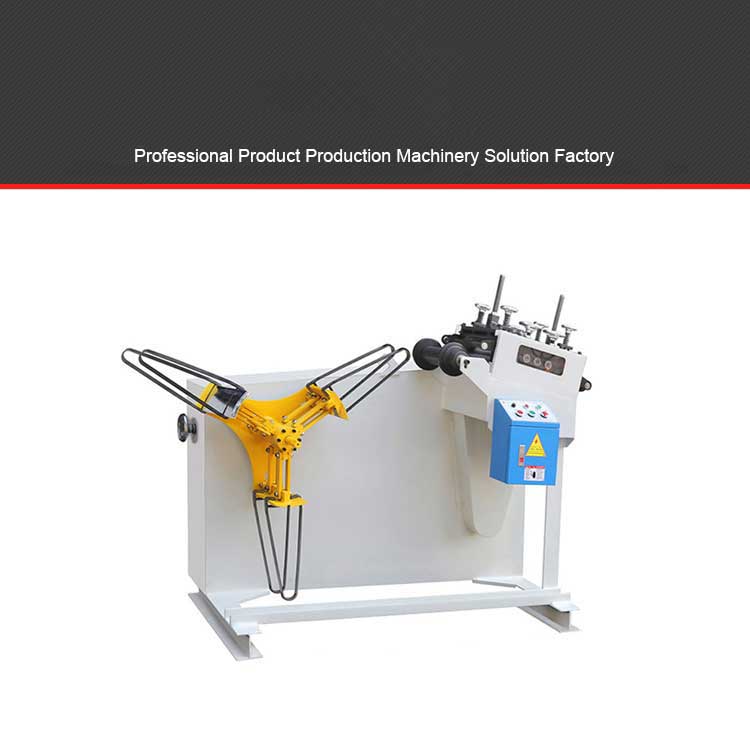

2 in 1 Socoje uncoiler leveler Manual Decoiling Stainless Steel Sheet Metal Hydraulic Decoiler Coil Strip Straightener Machine 1 set

from

$3,980.00

Ex Tax: $3,980.00

5 or more $3,565.00

- Stock: In Stock

- Model: SCJ006799

- SKU: SCJ006799

Products Sold: 0

Product Views: 904

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| Place of Origin | Guangdong, China |

| Weight (KG) | 2000 |

| warranty: | 1 Year |

| Key Selling Points | Long Service Life |

| Use | Sheet |

| Showroom Location | India, Malaysia |

| Applicable Industries: | Manufacturing Plant, Other |

| Marketing Type | Hot Product 2019 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | PLC, Motor |

| Power | Optional |

| OEM/ODM | Yes |

| Voltage | 380V or Optional |

| Dimension(L*W*H) | Customization |

| After-sales Service Provided | Video technical support, Online support |

| Factory Engineer | more than 100 people |

| Type | Straightener Feeder & Uncoiler |

| Function | High durability and easy operation |

| Straightening material | Metallic material |

| Control system | PLC(imported Brand) |

| Material | Stainless Steel |

| Color | White |

| Certificate: | CE SIO |

| Packaging and delivery | |

| Packaging Details | Can provide wooden box, or plastic film package |

| Port | SHENZHEN |

| Supply Ability | |

| Supply Ability | 30 Set/Sets per Month |

- Description

2 in 1 Socoje uncoiler leveler Manual Decoiling Stainless Steel Sheet Metal Hydraulic Decoiler Coil Strip Straightener Machine 1 set

MAIN FEATURES

● It can feed material for various thicknesses and feeding stroke length.

● It suits for high speed feeding, long stroke length feeding, to improve production capacity and feeding precision.

● It adopts pneumatic cylinder releasing method, without malfunction.

● Mechanical releasing method can be made according to customers requirement.

● High precision feeding, ±0.02mm

● Releasing device for a roller is high effective, as per press machine’s cam position electronic signal, and steel material thickness.

● Feeding roller is hollow, surface hardness is HRC60, with chrome plating.

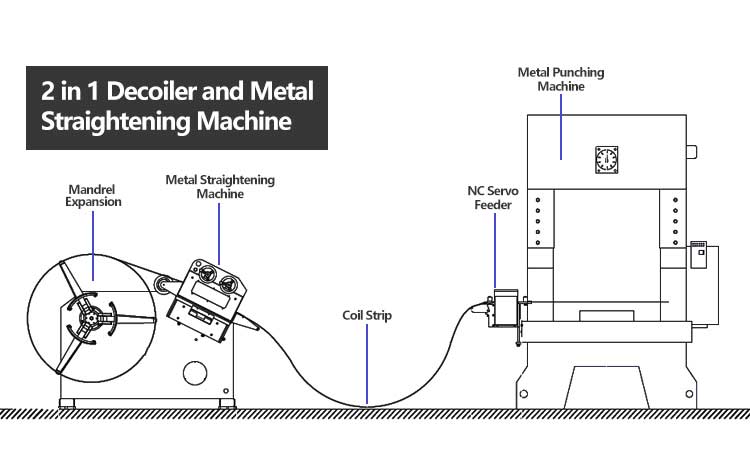

● Integrated with uncoiler and straightener, save volume, suitable for board processing. Automatically adjust feeding time according to output speed.

● Feeding roller is hollow, surface hardness is HRC60, with chrome plating.

● Use Japanese electromagnetic contact and electric parts, long service life.

● A stepless variable speed control is used normal and high speed operation, control by modern frequency converters, keep pace with straightening, stable feeding.

● Leveler inclines appropriately to reduce feeding loop distance.

● Constructed with highly rigid structure and designed with a powerful motorized feeder.

PRODUCT FUNCTION

Decoiler is for the metal coil(or other material )uncoiling to be straight and smooth ,then easily for the feeding to the machine like slitting,cut to length and roofing sheet,etc.It can be divided into manual decoiler and electric decoiler,hydraulic decoiler.The hydraulic decoiler whether has the loading car and the length of the guaiding is all customized.

Model | GO-150 | GO-200 | GO-300 | GO-400 | GO-500 | ||||

Material Width | 150mm | 200mm | 300mm | 400mm | 500mm | ||||

Material Thickness | 0.4-2.5mm | ||||||||

Coil Inner Diameter | 450-530mm | ||||||||

Coil Outer Diameter | 1200mm | ||||||||

Coil Weight | 500kg | 800kg | 1000kg | 1500kg | 2000kg | ||||

Expansion Style | Manual Operation | ||||||||

Motor | 1/2(HP) | 1(HP) | 2(HP) | 2(HP) | 3(HP) | ||||

Decoiling Machine

Single-end configurations are provided as standard, and Double-ended configurations can be provided to optimize production efficiency by lowering the coil changeover time. Most models are available as Traveling Reels that can be combined with automatic centering functions.

Custom engineering can be provided to meet any application demands.

Adopt parallel roller design, 3 up / 4 down, totally 7 rollers.

Adopt four point fine adjustment is adopted, which is more suitable for processing high-precision products. Adopt four point independent pressure to adjust the pressure of feeding roller for entrance and exit, which can prevent material deviation and deformation effectively.

Electric control box

Adopt silver alloy relay, full copper coil, flame retardant safety base, long lasting and durable.

Adopt safety protection adjustment circuit time delay relay, silver alloy contact, satisfied different delay ranges.

Adopt self-duplex flat button, the force is light, the key range is moderate, the building block type combination structure. The contact is made up of keto-base composite points with strong conductivity and large current, with a life span of up to 1 million times.

Surface hardness is HRC60, with chrome plating.

Constructed with highly rigid structure and designed,Provide a more stable processing platform

- Reviews