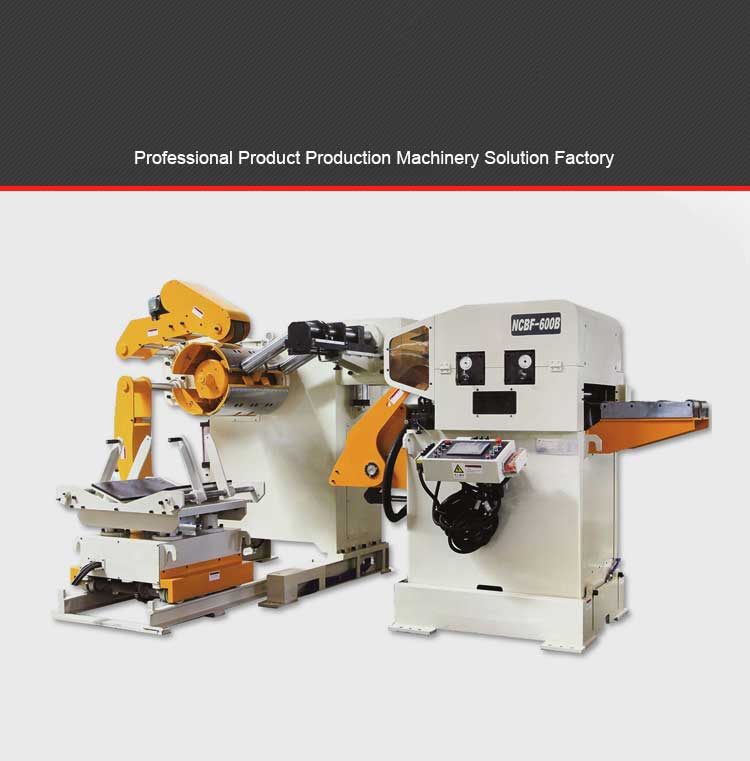

3 In 1 NC Servo Feeder Machine Line Roll Feeding Leveling Machine Straightener and Uncoiler For Metal Press Machine

from

$29,900.00

Ex Tax: $29,900.00

5 or more $25,900.00

- Stock: In Stock

- Model: SCJ006855

- SKU: SCJ006855

Products Sold: 0

Product Views: 210

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| Place of Origin | Guangdong, China |

| Weight (KG) | 5000 |

| warranty: | 1 Year |

| Key Selling Points | Long Service Life |

| Use | Sheet |

| Showroom Location | India, Malaysia |

| Applicable Industries: | Manufacturing Plant, Other |

| Marketing Type | Hot Product 2019 |

| Machinery Test Report | Provided |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | PLC, Motor |

| Power | Optional |

| OEM/ODM | Yes |

| Feeder motor | NC Servo Feeder |

| Voltage | 380V or Optional |

| Dimension(L*W*H) | Customization |

| After-sales Service Provided | Video technical support, Online support |

| Factory Engineer | more than 100 people |

| Type | Straightener Feeder & Uncoiler |

| Function | Feed metal strip to press machine |

| Control system | PLC(imported Brand) |

| Material | Stainless Steel |

| Color | White |

| Certificate: | CE SIO |

| Packaging and delivery | |

| Packaging Details | Can provide wooden box, or plastic film package |

| Supply Ability | |

| Supply Ability | 30 Set/Sets per Month |

- Description

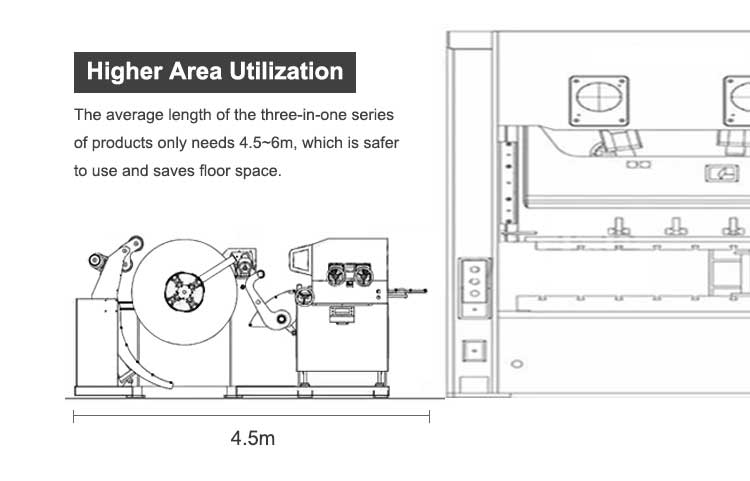

MAIN FEATURES

● Intelligent mechanized platform improves overall work efficiency and reduces error rate.

● The delivery speed can be adjusted according to product requirements, reducing waste and improving material use efficiency.

● Using a complete set of standard control system, it can be operated directly without worrying about data conversion and other issues.

● You can freely switch between punch master or device master according to your own needs, which maximizes the adaptability of the device and saves costs.

● The machine has the advantages of high universality, high precision, reliable performance and convenient operation.

NCBF Technical Parameters

Model | NCBF-400B | NCBF-600B | NCBF-800B | NCBF-1000B | |||

Material width | 50~400mm | 50~600mm | 50~800mm | 50~1000mm | |||

Materialthichness | 0.5~4.5mm | ||||||

Max.Coil outer diameter | φ1400mm | ||||||

Max.Coil weight | 5t | 7t | |||||

Straightening roller diameter | φ76mm×7(up4/down3) | ||||||

Feeding roller diameter | φ84mm | ||||||

Decoil power | 22kw | 3.7kw | |||||

Feeding speed | 0~20m/min | ||||||

Feeding accuracy | ≤0.2mm | ||||||

The height of standard discharging line | 1050mm-1250mm | ||||||

Standard direction | left→right | ||||||

Expansion style | Manual expansion | Hydraulic expansion | |||||

Product Details

Mandrel of uncoiler

The axis of the uncoiler is composed of four high-precision alloy plates, which can be adjusted according to the diameter of the material, which ensures stable and continuous output of the material.

There is a material width scale bar on the axis, which is convenient for aligning the machine position.

There are multiple guide rollers at the entrance of the straightening machine, which can be adjusted according to the width and thickness of the material at the entrance of the straightening machine, so that the material is more flat when it enters the punching machine.

The HMI controller is composed of a touch control screen and buttons, and the corresponding options can be selected according to the menu in the display to control the operating speed and size requirements of the machine.

The material outlet of the straightening machine is a plane composed of rollers, which can transfer the material to the punching machine smoothly and orderly.

The hydraulic pump motor is composed of a high-power AC motor and a set of cooling system. It can adjust the strength of power output according to the control signal of the controller. It can provide continuous power and pressure for the machine during operation.

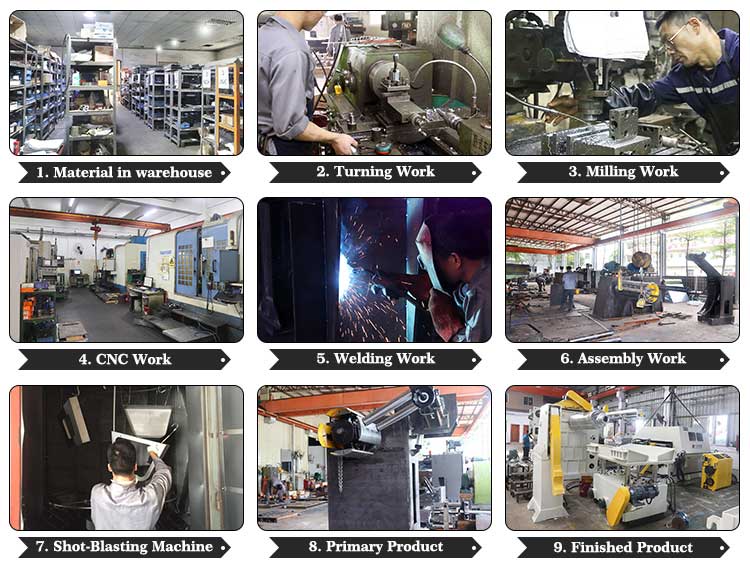

Production Workshop

- Reviews