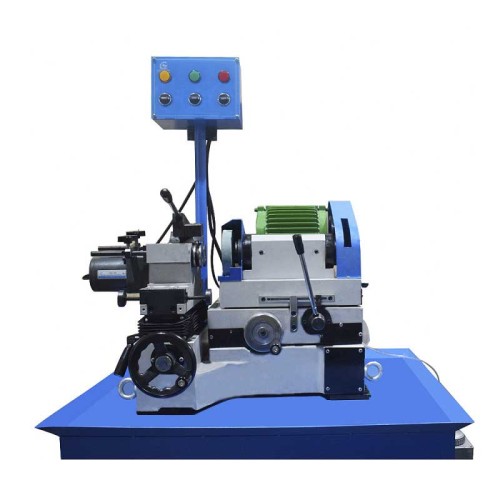

1" Swing Manual Socoje CNC Cylindrical Grinder 3 Phase 220V 60HZ 1HP 1 set

from

$1,999.00

Ex Tax: $1,999.00

- Stock: In Stock

- Model: SCJ004374

- SKU: SCJ004374

Products Sold: 0

Product Views: 289

Ask a Question About This Product

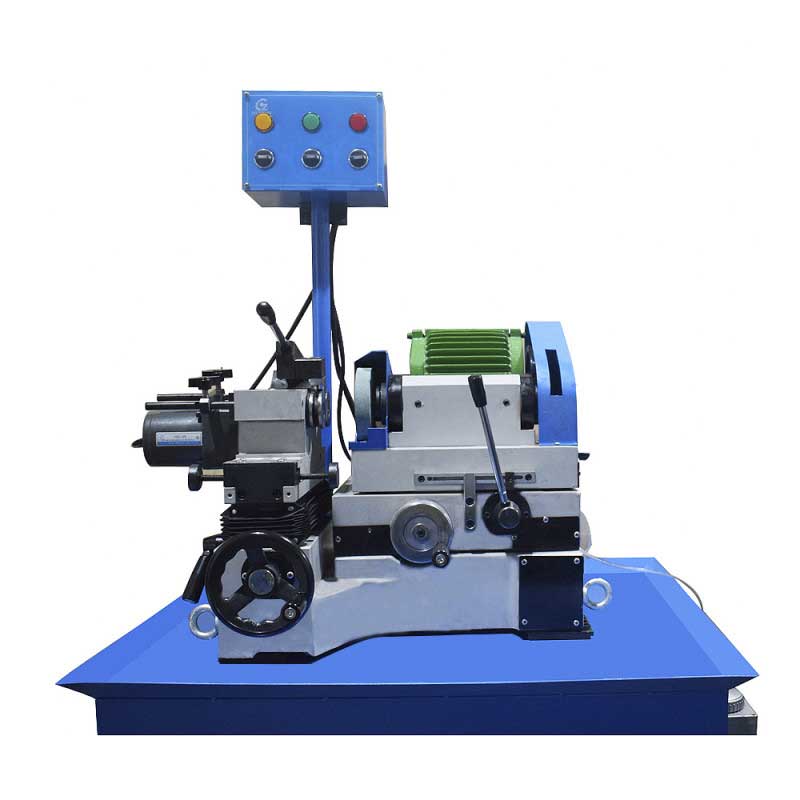

- Specifications

| attribute-list | |

| Model | DY-01 |

| Power | Three-phase, 220V, 60Hz |

| Max. Swiveling Diameter | 1" |

| Workhead Rotation Speed | 380 RPM |

| Workhead Spindle Rotation | Forward & Reverse |

| Wheel Spindle Speed | 8000 RPM |

| Grinding Wheel Size(O.D. x Width x I.D.) | 4" × 1-9/16" × 1" |

| Wheelhead Swivel Angle | +5°, -5° |

| Max. Wheelhead Travel | 2-3/4" |

| Handwheel Feed per Graduation | 0.0025" |

| Handwheel Feed per Revolution | 0.05" |

| Wheel Spindle Motor | 1 HP, 1.8 A, 3420 RPM |

| Workhead Motor | 25 W, 0.18 A, 1550 RPM |

| Packaging size | 26-37/64" × 31-1/2" ×66- 17/32" |

| Net weight | 440 lbs |

- Description

1" Swing Manual Socoje CNC Cylindrical Grinder 3 Phase 220V 60HZ 1HP 1 set

Automation and CNC Control:

The machine is equipped with a CNC system that allows for precise, programmable control of the grinding process.

The CNC controller manages the movement of the grinding wheel, workpiece, and other machine components based on pre-programmed instructions.

Cylindrical Grinding:

The workpiece is held between centers or mounted on a rotating chuck and is brought into contact with the rotating grinding wheel.

The grinding wheel removes material from the workpiece to achieve the desired dimensional accuracy, surface finish, and profile.

Precision Grinding:

CNC cylindrical grinders are capable of achieving high levels of dimensional accuracy, often within microns or sub-micron tolerances.

The CNC control and advanced grinding technology enable precise control over the grinding parameters, such as wheel speed, feed rate, and depth of cut.

Versatility:

CNC cylindrical grinders can handle a wide range of workpiece materials, including metals, ceramics, and composites.

They can perform various grinding operations, such as straight, taper, and profile grinding, as well as thread and gear grinding.

Automated Cycles and Routines:

The CNC system allows for the programming of automated grinding cycles and routines, which can optimize the grinding process and improve productivity.

These cycles can include features like automatic wheel balancing, dressing, and workpiece loading/unloading.

Monitoring and Diagnostics:

CNC cylindrical grinders often incorporate advanced monitoring and diagnostic capabilities to ensure consistent quality and performance.

This can include in-process measurement, tool condition monitoring, and real-time data analysis.

About this product

1. CNC cylindrical grinder Max. swiveling dia.: 1"

2. Manual id grinder Wheelhead Swivel Angle: +5°, -5°

3. Max. Workhead Travel: 2-3/4"

4. Power: Three-phase, 220V, 60 Hz

5. Suitable for External grinding

1" Swing Manual CNC Cylindrical Grinder 3 Phase 220V 60HZ 1HP

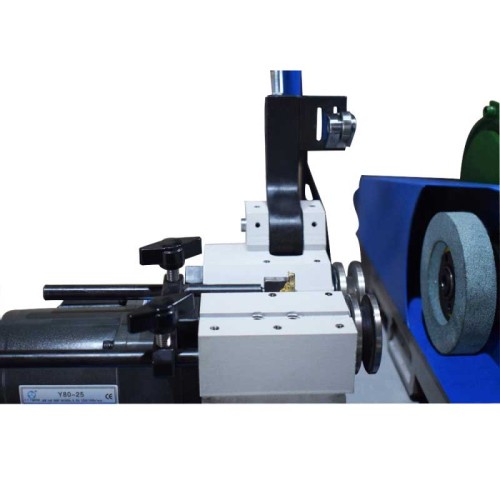

1. Precision-ground guide rail ensure maximum accuracy across the entire workplace length and accommodate high workplace weights.

1. Precision-ground guide rail ensure maximum accuracy across the entire workplace length and accommodate high workplace weights.

2. The adjustable grinding spindle features superior bearings and provides for maximum precision and surface quality.

3. Spindle of the wheel head uses the dynamic pressure bearing spindle of big-tapered telescope-feed and high-precision, which has the high rotation precision and long time maintenance.

4. Grinding wheel feed mechanism uses gear structure, which is flexible and accurate to operate.

5. The speed spindle head runs on precision bearings, assuring greater spindle stability and providing outstanding accuracy for external diameter grinding and face grinding.

- Reviews