- Stock: In Stock

- Model: SCJ009449

- SKU: SCJ009449

Available Options

Ask a Question About This Product

- Description

1hp (0.75kW) Stainless Steel Motor, 3 Phase, B3/ B5/ B14

Brief

Description

1hp stainless steel motor with 3 phase, TENV cooling type, IE 4 efficiency and class F insulation class. The stainless motor offers low noise, easy to clean and long service life.

Features

- Smooth stainless steel enclosures easy to clean and sanitize.

- IP65 for water protection rating ensures suitability for clean in place washdown procedures.

- Encapsulated windings prevent any water and moisture from reaching the windings.

- Low surface temperature with less operation costs due to high efficiency.

Specification

| Model | IEC-801 |

| Rated power | 1hp (750W) |

| Rated voltage | 208V~230V/ 460V |

| Number of pole | 2P |

| Phase | 3 phase |

| Cooling method | TENV |

| Frequency | 50/ 60Hz |

| Raged speed | 2950r/min |

| Mounting type | B3/ B5/ B14 |

| Stainless steel | 304 |

| Protection grade | IP65 |

| Insulation class | Class F |

| Protect Feature | Waterproof |

| Efficiency | IE 4 |

| Weight | 29kg |

| Certificate | CE, UL |

| Warranty | 12 months |

Dimension

| Mounting type | Frame size | Mounting dimensions (mm) | ||||||||||||||||||||

| A | A/2 | B | C | D | E | F | G | H | K | M | N | P | R | S | T | Flange Hole | Shaft Hole | AB | AC | AD | ||

| B3 | 80 | 125 | 62.5 | 100 | 50 | 19 | 40 | 6 | 15.5 | 80 | 10 | - | - | 144 | - | - | - | - | M6 | 150 | 144 | 135 |

| B14 | - | - | - | - | 19 | 40 | 6 | 15.5 | - | - | 100 | 80 | 120 | 0 | M6 | 3 | 4 | M6 | - | 144 | 135 | |

| B5 | - | - | - | - | 19 | 40 | 6 | 15.5 | - | - | 165 | 130 | 200 | 0 | 12 | 3.5 | 4 | M6 | - | 144 | 135 | |

Details

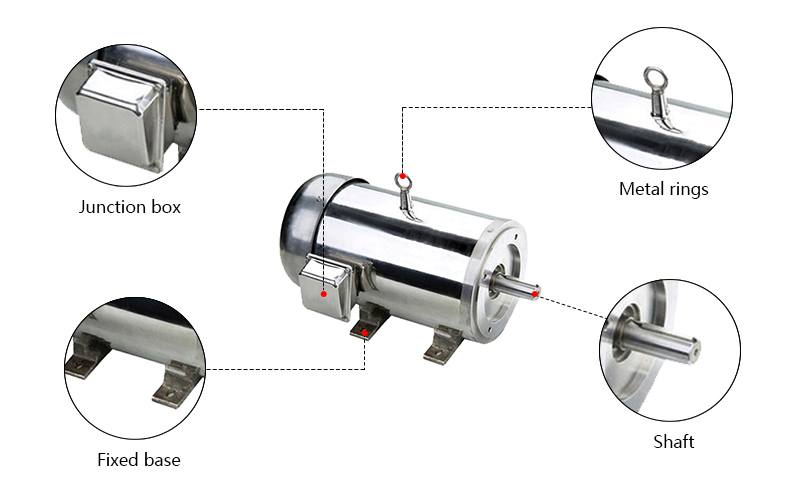

Tips: The Basic Structure of Stainless Steel Motor.

The stainless steel motor is mainly composed of a stator and a rotor. The stator is a stationary part, and the rotor is a rotating part. There is a certain air gap between the stator and the rotor.

The stator is composed of iron core, winding and base. The rotor consists of an iron core and windings. The rotor windings have squirrel cage and wire wound windings. The squirrel-cage rotor is formed by inserting copper bars into the rotor core slots, and then welding all the copper bars at both ends on two copper end rings; the wire-wound rotor winding is the same as the stator winding, and the windings composed of coils are put into the rotor core In the slot.

- Reviews