- Stock: In Stock

- Model: SCJ006496

- SKU: SCJ006496

Ask a Question About This Product

- Description

About this product

1. Clamping Force 5300 KN

2. Opening stroke 30.31 inch

3. Space between tie-bars (W × H) 32.28× 30.71 inch

4. Max. mold height 31.89 inch/ Min. mold height 12.99 inch

5. Servo motor with higher efficiency and quicker response

6. Machine dimension 347.24 × 80.71 ×111.02 inch

Product Description

Product Description

PRICE QUOTED INCLUDES INITIAL ONSITE SETUP/INSTALLATION, MOLD QUOTATION SERVICES, ROBOTIC AUTOMATION CONSULTATION, AND A MACHINE SELECTION CONSULTATION.

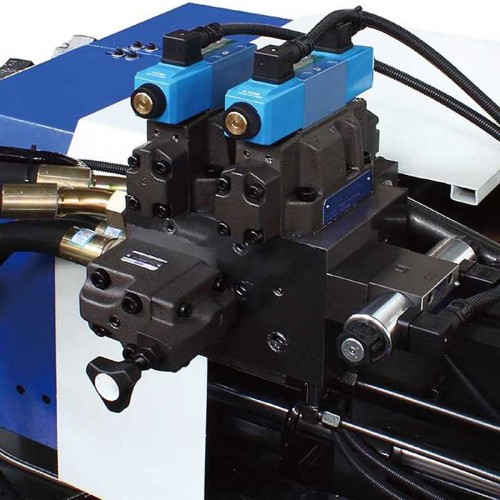

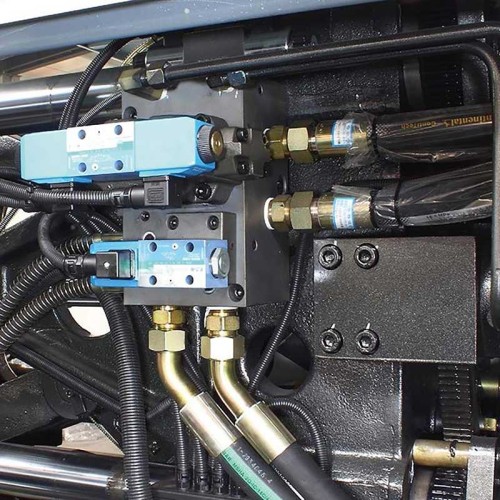

KS series High precision Servo Injection Machine is an updated version of previous model. The whole machine is designed in line with US standards to cater for the US customer’s needs. Unique design can provide better molding stability. Servo motor saves energy and cost. KONUS machine can keep the hydraulic oil temperature stable, which avoids overheating and reduces water consumption. Machines are equipped with several closed-loop supervison system to help with mold adjustment, impurity detection, speed control etc, which makes the operation safer.

KONUS can also provide tailored screws to customers, if they use raw materials such as PE/PP/ABS/PS/PC/PPS/CP/PET/UPVC/CP etc.

Several world-class brands have been chosen to be our electric component suppliers, which can guarantee the quality in the very beginning. We believe our machine can deliver better output, better quality control and better cost cut than others.

Under the same conditions, it can save 20%-80% energy compared with traditional models.

Product Information

Technical Details

| K-TEC530H | |||||

| VB | in3 | 253.554 | |||

| A | B | C | |||

| Injection Unit | Screw Diameter | inch | 2.756 | 2.953 | 3.150 |

| Screw L/D Ratio | L/D | 22.0 | 20.5 | 19.2 | |

| Injection Volume | in3 | 91.54 | 105.14 | 119.61 | |

| Shot Weight(PS) | OZ | 48.149 | 55.310 | 62.929 | |

| Injection Rate | in3/S | 29.41 | 33.50 | 38.14 | |

| Injection Pressure | Psi | 28863 | 25092 | 22046 | |

| Screw Speed | rpm | 200 | |||

| Clamping Unit | Clamping Force | KN | 5300 | ||

| Opening Stroke | inch | 33.07 | |||

| Space Between Tie-Bars(WxH) | inch | 32.68×31.5 | |||

| Max. Mold Height | inch | 32.68 | |||

| Min. Mold Height | inch | 13.78 | |||

| Ejector Stroke | inch | 9.45 | |||

| Ejector Force | KN | 150 | |||

| Others | Max. Pump Pressure | Psi | 2321 | ||

| Motor Power | KW | 43+36 | |||

| Heater Power | KW | 30.7 | |||

| Machine Dimension | in | 336.22×80.71×90.55 | |||

| Oil Tank Capacity | in3 | 48819 | |||

| Machine Weight | lbs | 39683 | |||

| Available Voltage | 380V/440V/460V/480V/530V- 3 Phase 60Hz | ||||

| Rated Current | 40.8A | ||||

Additional Information

Spare Parts (FREE) List of Plastic Injection Molding Machine

Sequence | Parts name | Quantity |

1 | "O" Ring | 1 Set |

2 | Seal Ring | 1 Set |

3 | Wrench | 2 Sets |

4 | Barrel Heater | 2 Pcs |

5 | Screw Head Heater | 1 Pc |

7 | Balance pad | 1Set |

8 | Extended nozzle | 1 Pc |

9 | Thermocouple | 2 Pcs |

10 | Contactor | 1 Pc |

11 | Machines manual | 1 Pc |

12 | Moulds Clamp | 1 Set |

Main Configuration of Konger KS Series

| |||

No. | Parts | Brand | Socoje |

1 | Controller | Techmation | China |

2 | Electron Components | Schneider | France |

3 | Switch | Schneider | France/Japan |

4 | Position Transducer (electronic ruler) | Novo | Germany |

5 | Motor | Phase | Italy |

6 | Pump | Sumitomo | Japan |

7 | Servo Driver | Inovance | China |

9 | Valve | Vickers | USA |

10 | Seal Ring | Hallite | UK |

- Reviews