High Precision 49 x 36 In 150W CO2 Laser Cutter Engraver Servo Motor

from

$9,600.00

Ex Tax: $9,600.00

- Stock: In Stock

- Model: SCJ004085

- SKU: SCJ004085

Products Sold: 0

Product Views: 316

Ask a Question About This Product

- Specifications

| attribute-list | |

| Model | MC-1250 |

| Laser Power | 150W CO² |

| Worktable dimension | 49" x 36" |

| COOLING TYPE | Water Cooling |

| Workbtable load | 330 lbs |

| Cutting ability (Acrylic) | 1-3/16 inch |

| Speed of positioning(X,Y) | 65.6 ft/min |

| Positioning accuracy (X,Y) | ±0.002"/39.4" |

| Gross power | ≤ 1500W |

| Operating Temperature | 32℉-104℉ |

| Repeatability accuracy | ±0.002" |

| Data Transfer Interface | USB 2.0 |

| Initial current | 13A |

| System Environment | Windows XP/2000/7/8/10 |

| Pressure of accessorial gas source | 0.6MPa |

| Operating Humidity | 5-95% |

| Position System | Red-light pointer |

| Graphic Format Supported | DXF, AI, PLT etc. |

| Overall dimensions(L×W×H) | 63" x 68.9" x 47.2" |

| Machine net weight | 400kg |

- Description

About this product

1. Laser Power: CO2 Sealed Glass 150W, Maximum cutting thickness for acrylic: 1.2" (30mm)

2. Working Area: 49" x 36", Workbtable load: 330 lbs(150 kg)

3. Power Supply: AC 220 V ± 10%, single phase, 60 Hz

4. MITSUBISHI servo motor & driver

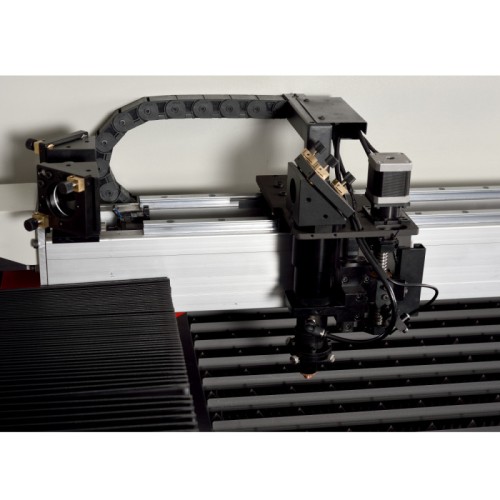

5. X,Y,Z Ball Screw & TBI linear Guide

6. Positioning accuracy (X,Y): ±0.002"/39.4"(±0.05mm/1000mm), Repeatability accuracy: ±0.002"(±0.05mm)

7. New frame structure, no deformation for at least 5 years

8. Perfect cutting thickness: Acrylic 30mm (1.2")

Packaging Method | Wooden Crate |

Packing size (L×W×H) | 72.8" x 70" x 66.1" |

Gross Weight | 1210 lbs (550kg) |

MC-1250/MC-2500 with high quality configuration: Here are industrial standard configuration including fixed beam optical laser system, cutting following system, Mitsubishi servo system, imported ball screw, water-cooling system, Red-light pointer,exhaust-air system, off-computer system so as to guarantee high precision and reliability meanwhile make the machine more cost-effective!

1. High precision, detailed capacity, and speed are key elements to obtain the best quality when laser cutting, this is why MINTECH incorporates Japanese Mitsubishi servo motors on the steel X and Y axis as well as digitally controlled Drivers. Servo technology is known for its high precision, smooth movements and the ability to operate without cogging at a high speed.

2. High qulity ball screw is a safe and fast movement system that delivers high precision and easy maintenance.

3. The machine comes with a USB input port for flash drives that allows you to load files into the internal memory and USB/Printer port (connection cable included) to connect it directly to a PC.

4. Perfect cutting thickness: Acrylic 30mm (1.2")

Main Accessories:

Packing List:

The number of package: 1 No.1 package No. Name specifications Remark 1 the main machine 1 MC-1250 2 air pipe 1 ODφ6 5m 3 surport unit 6 4 hoop 2 Ф200 5 vent-pipe 1 Ф200 6 support bar 50 7 toolbox 1 see toolbox below 8 water chiller 1 CW-5200 9 laser tube 1 150W 10 laser power 1 150W 11 fan 1 1.5KW 2640m³/h Toolobox 1 therm-hypersensitive paper 10 2 cross target 1 3 adhesive tape 1 4 absolute alcohol 1 5 clean paper 1 6 tampon 1 7 cutting head 1 including lock nuts 8 focus lens 2 9 nozzle 2 10 screwdriver+ 1 11 screwdrive- 1 12 monkey wrench 1 13 steel ruler 1 Length:150mm 14 hexagonal wrench 1 15 WF 10 For wire fixup 16 hoop 2 17 6-8 connecter 1 18 6-6 connecter 1 19 key 2 20 mirrors 5 21 Packing list 1 22 Limit switch 1 23 High voltage resistant tape 1 24 CD-ROM 1 Software

| The number of package: 1 | ||||

| No.1 package | ||||

| No. | Name | specifications | Remark | |

| 1 | the main machine | 1 | MC-1250 | |

| 2 | air pipe | 1 | ODφ6 | 5m |

| 3 | surport unit | 6 | ||

| 4 | hoop | 2 | Ф200 | |

| 5 | vent-pipe | 1 | Ф200 | |

| 6 | support bar | 50 | ||

| 7 | toolbox | 1 | see toolbox below | |

| 8 | water chiller | 1 | CW-5200 | |

| 9 | laser tube | 1 | 150W | |

| 10 | laser power | 1 | 150W | |

| 11 | fan | 1 | 1.5KW | 2640m³/h |

| Toolobox | ||||

| 1 | therm-hypersensitive paper | 10 | ||

| 2 | cross target | 1 | ||

| 3 | adhesive tape | 1 | ||

| 4 | absolute alcohol | 1 | ||

| 5 | clean paper | 1 | ||

| 6 | tampon | 1 | ||

| 7 | cutting head | 1 | including lock nuts | |

| 8 | focus lens | 2 | ||

| 9 | nozzle | 2 | ||

| 10 | screwdriver+ | 1 | ||

| 11 | screwdrive- | 1 | ||

| 12 | monkey wrench | 1 | ||

| 13 | steel ruler | 1 | Length:150mm | |

| 14 | hexagonal wrench | 1 | ||

| 15 | WF | 10 | For wire fixup | |

| 16 | hoop | 2 | ||

| 17 | 6-8 connecter | 1 | ||

| 18 | 6-6 connecter | 1 | ||

| 19 | key | 2 | ||

| 20 | mirrors | 5 | ||

| 21 | Packing list | 1 | ||

| 22 | Limit switch | 1 | ||

| 23 | High voltage resistant tape | 1 | ||

| 24 | CD-ROM | 1 | Software | |

Applications:

Widely used in cutting and engraving acrylic, wood, leather, cloth and other non-metallic materials.

Attentions:

- When cut some materials such as acrylic,

some harmful gas, smoke or powder may be produced. A purge kit (option) is

recommended.

- The materials for machining or its

output gas may be combustible, and the preventive methods should be adopted.

- Do not cut the high reflectivity

material which wavelength is 10.6μm such as copper, gold, aluminum etc.

- Do not cut PVC (polyvinyl chloride) with

a laser beam. The chemical heat reaction in combination with the humidity in

the air will produce hydrochloric acid. Hydrochloric acid is hazardous to the

operator and the laser system.

- Reviews