Socoje 10MM 20MM Laser Cutter Machines For processing hardware accessories 1set

from

$24,500.00

Ex Tax: $24,500.00

5 or more $23,500.00

9 or more $22,500.00

- Stock: In Stock

- Model: SCJ006604

- SKU: SCJ006604

Products Sold: 0

Product Views: 373

Available Options

Ask a Question About This Product

- Specifications

| Industry-specific attributes | |

| Cutting speed | 120 m/min |

| Laser Type | Fiber Laser32 |

| Control System Brand | SOCOJE |

| Cooling Mode | WATER COOLING |

| Other attributes | |

| Condition | New |

| Applicable Material | Metal |

| CNC or Not | Yes |

| Place of Origin | Jiangsu, China |

| Cutting Area | 3000*1500 |

| Laser Source Brand | MAX |

| Weight (KG) | 4800 KG |

| warranty: | 1 Year |

| Key Selling Points | High-accuracy |

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction worksxa0, Energy & Mining, Other, Advertising Company |

| Machinery Test Report | Provided |

| Mode of Operation | continuous wave |

| Configuration | 3-axis |

| Video outgoing-inspection | Provided |

| Features: | Water-cooled |

| Warranty of core components | 1 Year |

| Core Components | Pressure vessel, Motor, Gear, Gearbox, Engine |

| Products handled | Sheet Metal |

| Control Software | CYPCUT |

| Graphic Format Supported | AI, PLT, DXF, Dst, Dwg, LAS, DXP |

| Cutting Thickness | 0.5-35 mm |

| Laser Head Brand | SOCOJE |

| Product name: | Fiber Laser Metal Cutting Machine |

| Servo Motor Brand | SOCOJE |

| Guiderail Brand | SOCOJE |

| Type | Fiber Lasr Cutting |

| Application | LASER CUTTING |

| Function | Cutting Metal Materials |

| Optical Lens Brand | II-VI |

| Packaging and delivery | |

| Packaging Details | Container |

| Port | Nanjing |

| Supply Ability | |

| Supply Ability | 50 Set/Sets per Month |

- Description

Socoje 10MM 20MM Laser Cutter Machines For processing hardware accessories 1set

Products Description

HARSLE HS CNC Fiber Laser Cutting Machine

The CNC fiber laser cutting machine has a stable performance and high precision, using a German brand reducer to ensure that the machine starts and stops ay high speed, and a double drive rack and pinion transmission system to guarantee performance. All electrical compoments and lasers are housed in the control cabinet, with excellent dust-proof design to enhance the life of the electrical components. The outside of the control cabinet is equipped with an air conditioner with automatic constant temperature to prevent damage to the components in summer.

Product Details

Switzerland RAYTOOLS Laser Head

Optimization of the optical configuration smooth and efficient air flow design rotary knob focus adjustment more easy and flexible.

France MOTOREDUCER

Satellite gears are double-supported on hardened and ground shafts with full-complement needle bearings increasing torsional stiffness.

Japan YASKAWA Servo Motor

The increased power demands of largeautomation components utilize the robust performance of SGM7G.

Standard Punch and Multi-V Die

These bearing housings have square flange which can be easily attached to a machine with four bolts.with its simple mounting face,this bearing unit is widely used.

Laser Source

We have two types of laser sources: MAXPHOTONICS and IPG, Which can be supplied according to customer request.

Japan SMC Pneumatic Components

Stepless control of air pressure proportional to an electrical signal. Compact/lightweight (Integrated communication parts.)

France Schneider Electronic Component

Circuit protection against short-circuit currents,overload currents.

Auto Lubrication System

Electrical lubrication is a kind of gear pump with rational construction, great performance,complete functions.

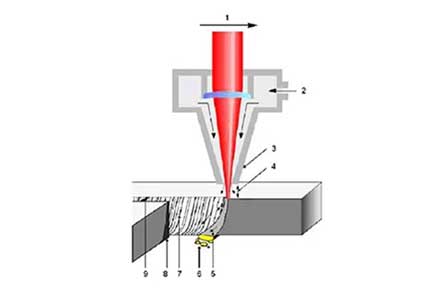

Working Principle

1.Moving Direction

2.Auxiliary Gas

3.Nozzle

4.Nozzle Distance

5.Molten Material

6.Residues

7.Cutting Section

8.Heat Affected Zone

9.Joint-Cutting

Help You to Solve the Following Problems Easily

SAVE MAN POWER | ■ Save manpower cost | ||||||

■ Solve the problem- | |||||||

High cost and difficult mangement of labor force | |||||||

HIGH EFFICIENCY | ■ High speed, convenient operation | ||||||

■ Solve the problem- | |||||||

Artificial or common mechanical processing with low speed, low efficiency | |||||||

GOOD QUALITY | ■ High precision smooth section is convenient for welding processing or assembling | ||||||

■ Solve the problem- | |||||||

Poor precision,coarse section,large slit | |||||||

STANDARDIZATION | ■ Computer operation standardization production | ||||||

■ Solve the problem- | |||||||

Batch job error | |||||||

LOW COST | ■ Almost zero maintenance cost | ||||||

■ Solve the problem- | |||||||

The equipment maintenance cost is high,the continuous investment | |||||||

ENVIRONMENTAL PROTECTION | ■ High-eficiency laser source,dust and smoke treament device | ||||||

■ Solve the problem- | |||||||

High energy consumption,serious pollution | |||||||

Fine Processing

Low cost in use | power consumption is only 20-30% of CO2 laser | ||||||

High speed | 2-3 time faster than yag or CO2 laser | ||||||

High accuracy | Fine laser beam,slim kerf | ||||||

Low maintenance | Almost zero maintenance cost | ||||||

Installation Instructions

1 | Machine tool body | 1 set | HARSLE |

2 | X、Y axis gear rack | 1 set | YYC -Taiwan |

3 | Linear guide rail | 1 set | HIWIN- Taiwan |

4 | Servo motor and driver | 4 sets | YASKAWA/Schneider |

5 | Reducer | 3 sets | Japan SHIMPO |

6 | Solenoid valve | 1 set | Japan SMC |

7 | Air cylinder | 1 set | Japan SMC |

8 | Proportional valve | 1 set | Japan SMC |

Manufacturing Technique

Cutting

Lathe

Milling

Drilling

Welding

Boring

- Reviews