- Stock: In Stock

- Model: SCJ009328

- SKU: SCJ009328

Available Options

Ask a Question About This Product

- Description

Nema 11 Stepper Motor Linear Actuator, 2 phase, 4.4V, 0.96A

Brief

Description

Nema 11 Stepper Motor Linear Actuator with 4.4V rated voltage and 0.96A rated current, holding torque of 12.5 Oz-in, precision leadscrew and higher IP protection. It is widely used in many applications such as X-Y tables, optical scanning equipment, medical valve and pump equipment etc.

Stepper Motor Linear Actuator Specification

| Model Type | External Shaft | Non-Captive Shaft |

| 28H45-0674AST | 28H45-0674GTS | |

| Weight | 3 kg | |

| Length | 45 mm | |

| Screw Diameter | 8 mm (0.315 inch) | |

| Screw Lead | 8 mm/rev (0.315 inch/rev) | |

| Travel Per 1.8 Step | 0.04 mm/step (0.00157 inch/step) | |

| Phase | 2 phase | |

| Step Angle | 1.8° | |

| Rated Voltage | 4.4 V | |

| Rated Current | 0.96 A | |

| Resistance | 4.6 Ω | |

| Holding Torque | 12.5 Oz-in | |

| Number of Leads | 6 | |

| Rotor Inertia | 18 g-cm2 | |

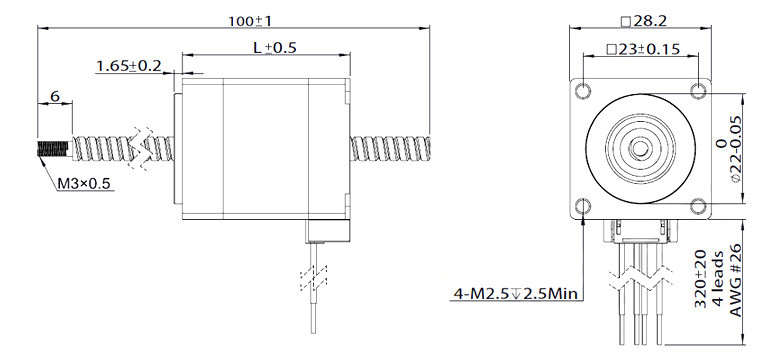

Stepper Motor Linear Actuator Dimension (Unit=mm)

1. Non-captive shaft style

L=45mm

2. External shaft style

L=45mm

Details

Tips: Stepper motor linear actuator in machine tool device

The application of stepper motor linear actuator in machine tool device can guarantee a high performance level and has simpler motor drive device that transforms rotatory movement into linear motion compared with traditional motor drive device. Because the linear motor is directly connected with the moving load, there is no back clearance between motor and load and the compliance is small.

1. Linear drive device can easily achieve the speed of minimum of 1um/s and maximum of 5m/s. The linear drive system can guarantee a constant speed characteristic, with a speed deviation of 0.01%. In applications which require higher accelerated speed, smaller linear stepper motors can easily provide accelerated speed greater than 10g while traditional motor generally produces accelerated speed within the range of 1g.

2. The stepper linear actuator has a simple structure and is composed of few components, so it needs less lubrication. It means that it has a longer service life and a relatively clean operation. In comparison, the traditional drive system consists of more than 20 components, including motor, coupling, ball screw, U block, bearing, bolster and lubrication system.

- Reviews