- Stock: In Stock

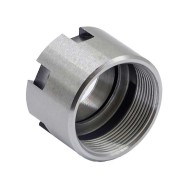

- Model: SCJ005132

- SKU: SCJ005132

Ask a Question About This Product

- Specifications

| attribute-list | |

| Type | Standard |

| Size | ER11A |

| Thread Size(T) | M14 x 0.75 |

| Outside Diameter( D) | 0.75" (19 mm) |

| Overall Length (L) | 0.44" (11.3 mm) |

| Net Weight | 0.04 lbs |

| Gross Weight | 0.05 lbs |

| Meas | 0.76" × 0.76" × 0.45" |

- Description

1. ER11A Collet Nut has an internal thread of M14 X 0.75 pitch

2. Outside diameter is 0.75" (19 mm)

3. ER11A Collet Nut holds all ER11 collets

4. ER11A-Wrench works on this collet nut

5. Balanced to 20000rpm at G2.5

6. Material: 20CrMnTi.

7. Made from alloy steel hardened to 50-53 HRC

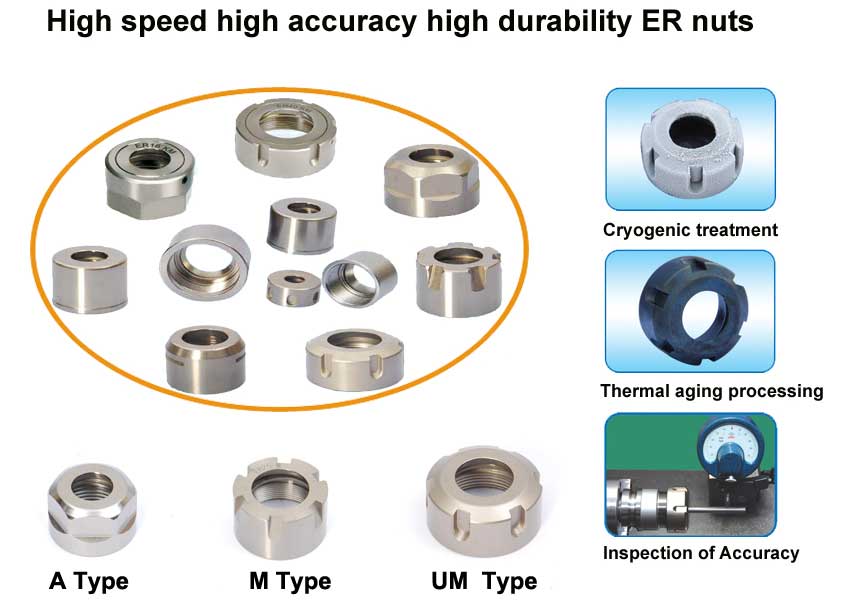

High speed high accuracy high durability ER-A Type nuts

High Precision Accessories ER collet nut for ER type handle, the knife rod, extension rod nut.Selection of high quality spring steel, has a higher flexibility and service life.The clamping force, clamping range, high precision, used for boring, milling, drilling, tapping, grinding and engraving processing. ER collet all through high precision grinding, precision manufacturing line with the German DIN 6499 specifications.

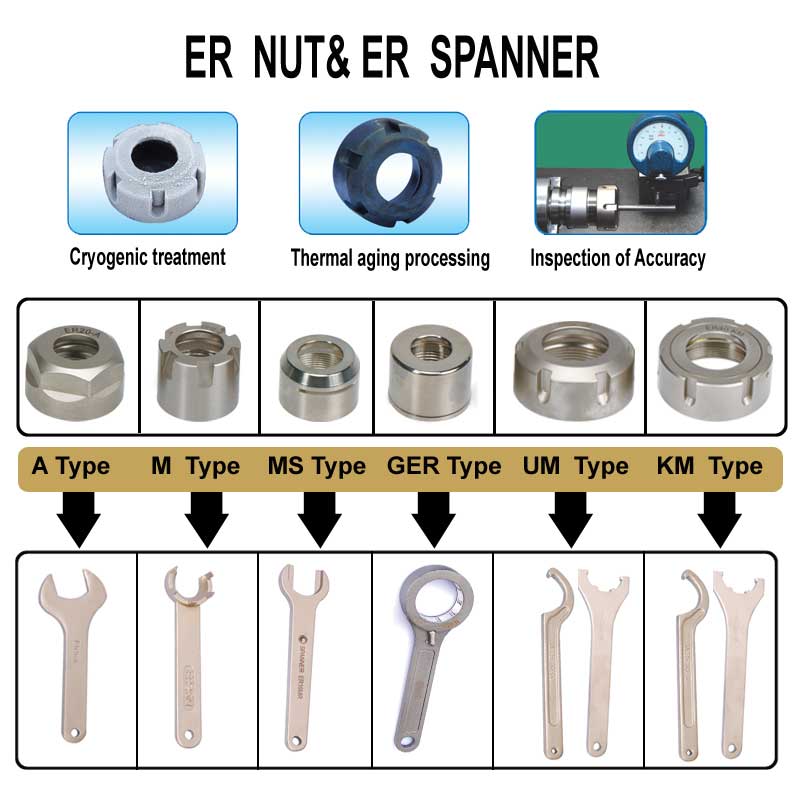

We also have many kinds of NUTS, such as, A type, GER type, MS type, UM type, M type, KM type, NER type, and so on. The size of ER-M Type is ER16UM, ER20UM, ER25UM, ER32UM, ER40UM, ER50UM.

Comprehensive features of ER-A nuts

1. Material: 20CrMnTi.

2. Made from alloy steel hardened to 50-53HRC

3. Heat treatment and thermal aging treatment have improved the stability of accuracy and dimensions.

4. Thread and a slope of 30 degrees have once molding processed. The tolerance class of thread use 4H, accuracy detected one by one.

5. Pre-balance is G2.5-20000RPM.

6. Surface coating processing treatment,improve surface hardness and endurance, cleaness better, antirust, accuracy more stable, surface more smooth, feel comfortable, appearance nice.

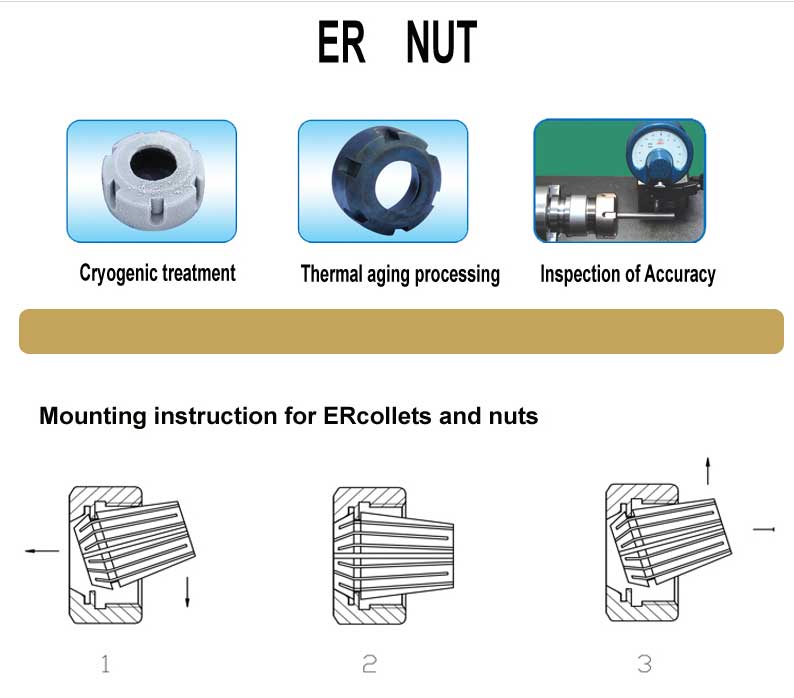

How to install the collet nut?

Operation is shown in the figure above

1. Put the collet into the nut, turn the collet slightly. Push it into the nut at the offered direction evenly when the offset flange sinks into the undercut of the collet.

2. Fix the nut and the collet on the spindle rotate the nut until the collet is in pressing, Wipe the straight shank of cutter, and instert it into the polot hole. Tighten the nut with a wrench tilll the cutter is clamped heavily(Caution: never tighten the nut without cutter in it for it will break).

3. When changing the tool. Loosen the nut and it shall bring out the collet and the cutter together. And then draw the cutter out push out slightly the collet in the offered direction, it shall be ready for any change of the cutter.

Features:

The special structure is for balance to make sure the status of circular uniform distribution.

The collet chuck will not be loosened during machining, and please assemble and disassemble the chuck as the marked direction.

- Reviews