- Stock: In Stock

- Model: SCJ006735

- SKU: SCJ006735

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| Place of Origin | Guangdong, China |

| Weight (KG) | 200 |

| warranty: | 1 Year |

| Key Selling Points | Easy to Operate |

| Use | Sheet |

| Showroom Location | Malaysia |

| Applicable Industries: | Manufacturing Plant |

| Marketing Type | Hot Product 2019 |

| Machinery Test Report | Provided |

| Relase system | pneumatic type |

| feeder | roller feeder |

| Video outgoing-inspection | Provided |

| Warranty of core components | 1 Year |

| Core Components | PLC, Motor |

| Max material width | 700mm |

| Material thickness | 0-3.5mm |

| Power | 1.5kw |

| Voltage | 3 Phase 220V/380V/50HZ |

| Type | Feeder Machine |

| Usage | metal sheet strip coil |

| Weight | 200kg |

| Motor | Japan YASKAWA |

| Certificate: | CE Certificate |

| Packaging and delivery | |

| Packaging Details | plywood box, plywood pallet. |

| Port | SHENZHEN |

| Supply Ability | |

| Supply Ability | 30 Set/Sets per Month |

- Description

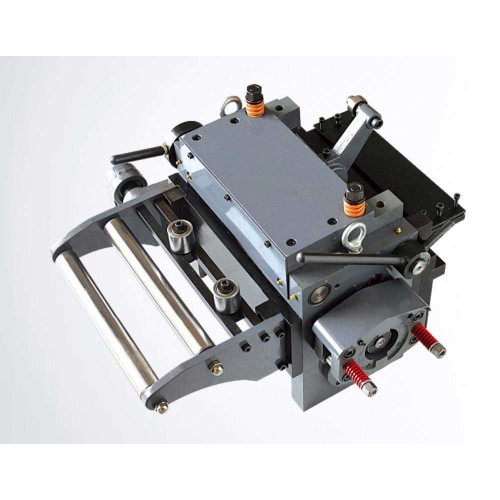

High Speed Roller Feeder

Structures of the machine

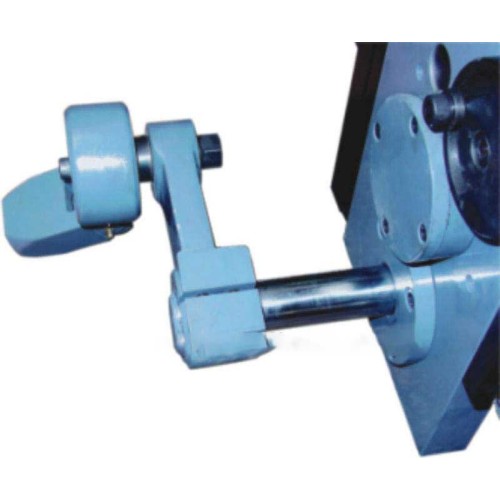

1. unilateral bearing(Made in Germany)

Embedded in the ultra-carbide, and with roller bearings and wear resistance, It is safety, high precision and long life. The gears are re-grinding by heat-treated HRC600 with high transmission accuracy.

2. Roller wheel

Applies hollow, light weight, small swing inertia, can be stopped immediately, to ensure the accuracy of feed. Heat-treated HRC60. Hard chrome re-grinding, high hardness, excellent wear resistance, long life.

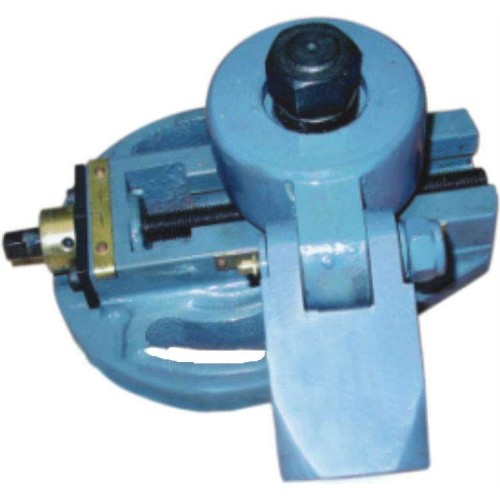

3. Disc brakes(General brake)

Applies advanced clutch to make the two sides fullcontact, long life, good stability, high precision.

4. Reverse facing device

(1)The structure is like the one-way device, can control the wheel with considerable precision, and will not cause the next wheel to have the slightest retrogression phenomenon after the long-term use, the stability and precision is quite high.

(2).Will not lead to condition that down roller reverse when the brake failure and the distance is not correct caused by the residual oil spilled during the stamping,

(3)It is not easy to exist high temperature.

(4)Comes with super-carbide and rollers, which are not easy to wear.

(5)The action way is the circular motion of the roller, rather than the straight motion of the four guide posts, so there will be no bite-killing.

(6)The twisting power required for small friction is reduced, and the rotating mechanism is less likely to be damaged.

(7)The reverse device can be configured at a speed of up to 30 m/min, generally 20 m/min, and increases 50% efficiency .

(8)Special structure, increased service life.

Advantages

1. Continuity: continuous processing for multiple engineering

2. High speed: up to 600 times per minute

3. Universality: regardless of the width and thickness of the material, just adjust the feeder to fit the mold can be used.

4. Simple and practical construction.

5. Low failure rate and easy maintenance.

Form:

Single type: suitable for coil (thickness of 0.15mm or more) single product or continuous punching products.

Double: suitable for coil(thickness 0.15mm or less) short-foot material, single-product continuous punching products.

Feeding accuracy:

Depending on the number of swings and the length of the feed varies (generally its accuracy is 0.03m), if the end of the road positioning, but also can get 0.01mm accuracy.

Specification:

Model | Strip Width (mm) | Stroke.Max(mm) | Strip Thickness (mm) | Material Line Height (mm) |

LH-105NS | 100 | 50 | 0-1.6 | 55-100 |

LH-205NS | 200 | 50 | 0-1.6 | 55-100 |

LH-255NS | 250 | 50 | 0-1.6 | 55-100 |

LH-305NS | 300 | 50 | 0-1.6 | 55-100 |

LH-405NS | 400 | 50 | 0-1.6 | 55-100 |

LH-505NS | 500 | 50 | 0-1.6 | 55-100 |

LH-605NS | 600 | 50 | 0-1.6 | 55-100 |

LH-138NS | 130 | 80 | 0-1.6 | 60-120 |

LH-1310NS | 130 | 100 | 0-3.5 | 70-140 |

LH-2010NS | 200 | 100 | 0-3.5 | 70-140 |

LH-1315NS | 130 | 150 | 0-3.5 | 70-140 |

LH-2015NS | 200 | 150 | 0-3.5 | 70-140 |

LH-5010NS | 500 | 150 | 0-3.5 | 70-140 |

LH-6015NS | 600 | 150 | 0-3.5 | 70-140 |

LH-1320NS | 130 | 200 | 0-3.5 | 70-140 |

LH-2020NS | 200 | 200 | 0-3.5 | 70-140 |

LH-7020NS | 700 | 200 | 0-3.5 | 70-140 |

LH-7030NS | 700 | 300 | 0-3.5 | 100-190 |

- Reviews