LM12UU Metric Size Linear Ball Bearings with Double Seals

from

$9.15

Ex Tax: $9.15

- Stock: In Stock

- Model: SCJ009732

- SKU: SCJ009732

Products Sold: 0

Product Views: 463

Available Options

Ask a Question About This Product

- Description

Brief

Linear motion 12mm ball bushing has a steel outer ring with grooves for a circlip and a polyamide ball retainer with 4 ball circuits. It has elastomer seals from both sides. Cavities can also capture invading dirt, preventing potential blockages. Smooth moving, low friction, high rigidity and long life.

Description

Closed type ball bushing has a 12mm bore with double side rubber seal. It can provide low friction motion along a single axis, hence find a wide range of applications in DIY and robotics prototyping. Easy assembly by just pressing in - no additional retention necessary.

Specifications

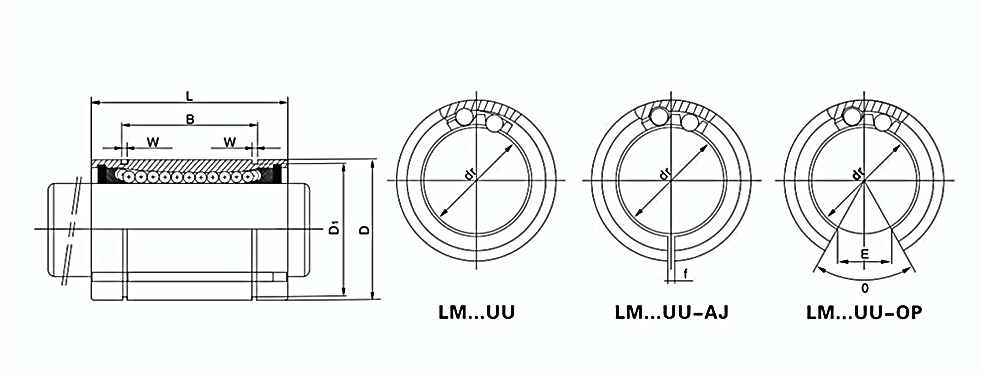

| Nominal shaft diameter | Resin retainer | dr | ||||||||||

| LM…UU | Ball circuit | Weight | LM…UU-AJ | Ball circuit | Weight | LM…UU-OP | Ball circuit | Weight | mm | Tolerance | ||

| Precision | High | |||||||||||

| 8mm | LM8UU | 4 | 15g | LM8UU-AJ | 4 | 14.7g | - | - | - | 8 | 0 -6μm | 0 -9μm |

| 10mm | LM10UU | 4 | 29.5g | LM10UU-AJ | 4 | 29g | LM10UU-OP | 3 | 23g | 10 | ||

| 12mm | LM12UU | 4 | 31.5g | LM12UU-AJ | 4 | 31g | LM12UU-OP | 3 | 25g | 12 | ||

| 16mm | LM16UU | 5 | 69g | LM16UU-AJ | 5 | 68g | LM16UU-OP | 4 | 52g | 16 | ||

| 20mm | LM20UU | 5 | 87g | LM20UU-AJ | 5 | 85g | LM20UU-OP | 4 | 69g | 20 | 0 -7μm | 0 -10μm |

| 25mm | LM25UU | 6 | 220g | LM25UU-AJ | 6 | 216g | LM25UU-OP | 5 | 188g | 25 | ||

| 30mm | LM30UU | 6 | 250g | LM30UU-AJ | 6 | 245g | LM30UU-OP | 5 | 210g | 30 | ||

| 35mm | LM35UU | 6 | 390g | LM35UU-AJ | 6 | 384g | LM35UU-OP | 5 | 335g | 35 | 0 -8μm | 0 -12μm |

| 40mm | LM40UU | 6 | 585g | LM40UU-AJ | 6 | 579g | LM40UU-OP | 5 | 500g | 40 | ||

| 50mm | LM50UU | 6 | 1580g | LM50UU-AJ | 6 | 1560g | LM50UU-OP | 5 | 1340g | 50 | ||

| 60mm | LM60UU | 6 | 1860g | LM60UU-AJ | 6 | 1820g | LM60UU-OP | 5 | 1610g | 60 | 0 -9μm | 0 -15μm |

| Major dimensions and tolerance | Eccentricity | Radial clearance (Max) | Basic load rating | ||||||||||||

| D | L | B | W | D1 | h | h1 | θ | ||||||||

| mm | Tolerance | mm | Tolerance | mm | Tolerance | Precision | High | Dynamic | Static | ||||||

| 15 | 0 -11μm | 24 | 0 -200μm | 17.5 | 0 -200μm | 1.1mm | 14.3mm | 1mm | - | - | 8μm | 12μm | -3μm | 274cN | 392cN |

| 19 | 0 -13μm | 29 | 22 | 1.3mm | 18mm | 1mm | 6.8mm | 80° | -4μm | 372c N | 549co N | ||||

| 21 | 30 | 23 | 1.3mm | 20mm | 1.5mm | 8mm | 80° | 510c N | 784co N | ||||||

| 28 | 37 | 26.5 | 1.6mm | 27mm | 1.5mm | 11mm | 80° | -6μm | 774c N | 1180co N | |||||

| 32 | 0 -16μm | 42 | 30.5 | 1.6mm | 30.5mm | 1.5mm | 11mm | 60° | 10μm | 15μm | 882c N | 1370co N | |||

| 40 | 59 | 0 -300μm | 41 | 0 -300μm | 1.85mm | 38mm | 2mm | 12mm | 50° | 980c N | 1570co N | ||||

| 45 | 64 | 44.5 | 1.85mm | 43mm | 2.5mm | 15mm | 50° | -8μm | 1570c N | 2740co N | |||||

| 52 | 0 -19μm | 70 | 49.5 | 2.1mm | 49mm | 2.5mm | 17mm | 50° | 12μm | 20μm | 1670c N | 3140co N | |||

| 60 | 80 | 60.5 | 2.1mm | 57mm | 3mm | 20mm | 50° | -10μm | 2160c N | 4020co N | |||||

| 80 | 100 | 74 | 2.6mm | 76.5mm | 3mm | 25mm | 50° | -13μm | 3820c N | 7940co N | |||||

| 90 | 0 -22μm | 110 | 85 | 3.15mm | 86.5mm | 3mm | 30mm | 50° | 17μm | 25μm | 4700c N | 10000co N | |||

Tips: Guide to using Linear Ball Bearings

Linear ball bearings find a wide range of applications in automation industry. To make the most of these products, we need to pay attention to the following points:Grease may be applied prior to use to improve smoothness.

- Inside a linear ball bearing, the ball bearings themselves contact the smooth shaft directly. This means the shaft must be lubricated from time to time in order to keep the system running well. Successful operation of linear ball bearing systems is highly contingent on the presence of saturating lubrication at every single rotation of the shaft within the bushing. Note that different types of lubricating oil can not be mixed, otherwise the mixed oil will not improve the performance and will even cause adverse effects. Selecting the right grease for specific applications is critical. Maintain lubrication of optical shafts and guides during operation.

- To minimize the wear of linear bearings during operation is another significant point. It’s natural even for SOCOJE's linear bearings with such high quality and great performance to have abrasion after long-time use. So maintaining lubrication at every single rotation of the shaft will be helpful for reducing abrasion and extending life span.

- Do not disassemble the linear bearing by yourself. If you do need to disassemble the device, ask professionals for help lest any accessory gets lost in your disassembly.

- The rolling elements in the bearing cartridge can be lubricated and sealed completely in between the inner and outer raceways of the bearing in order to prevent any exposure from environmental contaminants. Bearings with oil seals on both sides can work in places where there is a lot of dust or where foreign matter is easy to invade.

- Require regular cleaning and maintenance.

- Reviews