LM8UU Metric Size Linear Ball Bearings with Double Seals

from

$6.54

Ex Tax: $6.54

- Stock: In Stock

- Model: SCJ009730

- SKU: SCJ009730

Products Sold: 0

Product Views: 527

Available Options

Ask a Question About This Product

- Description

Brief

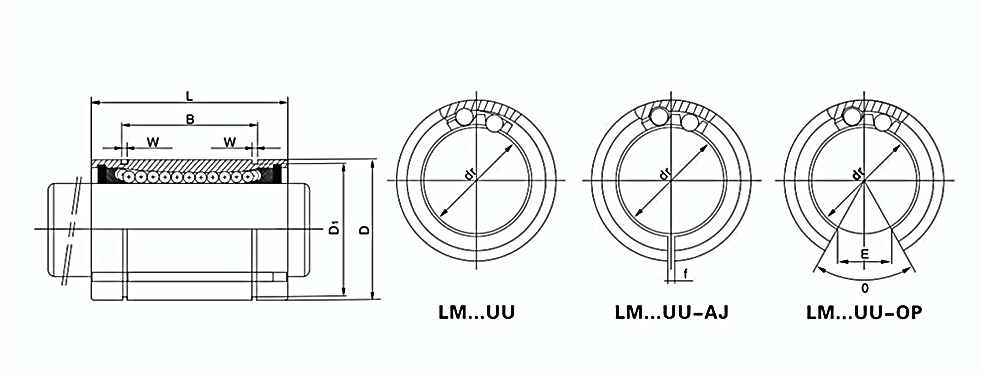

This 8 x 15 x 24 mm (LM8UU) linear ball bearing works with 8mm shafts, compact and lightweight, made of carbon steel material with ball lubrication in the tracks for high capacity and long life span. Suitable for use in a mounted slide unit to carry components. Double seal-closed types, open types and adjustable types are optional.

Description

Low cost linear ball bushings for most applications. These items are constructed with hardened steel segments for ultra-smooth, long-lasting linear motion. Inner cavities serve as lubrication reservoirs for long lubrication. These bearings have proven to be long lasting and provide precise low friction linear movement.

Specifications

| Nominal shaft diameter | Resin retainer | dr | ||||||||||

| LM…UU | Ball circuit | Weight | LM…UU-AJ | Ball circuit | Weight | LM…UU-OP | Ball circuit | Weight | mm | Tolerance | ||

| Precision | High | |||||||||||

| 8mm | LM8UU | 4 | 15g | LM8UU-AJ | 4 | 14.7g | - | - | - | 8 | 0 -6μm | 0 -9μm |

| 10mm | LM10UU | 4 | 29.5g | LM10UU-AJ | 4 | 29g | LM10UU-OP | 3 | 23g | 10 | ||

| 12mm | LM12UU | 4 | 31.5g | LM12UU-AJ | 4 | 31g | LM12UU-OP | 3 | 25g | 12 | ||

| 16mm | LM16UU | 5 | 69g | LM16UU-AJ | 5 | 68g | LM16UU-OP | 4 | 52g | 16 | ||

| 20mm | LM20UU | 5 | 87g | LM20UU-AJ | 5 | 85g | LM20UU-OP | 4 | 69g | 20 | 0 -7μm | 0 -10μm |

| 25mm | LM25UU | 6 | 220g | LM25UU-AJ | 6 | 216g | LM25UU-OP | 5 | 188g | 25 | ||

| 30mm | LM30UU | 6 | 250g | LM30UU-AJ | 6 | 245g | LM30UU-OP | 5 | 210g | 30 | ||

| 35mm | LM35UU | 6 | 390g | LM35UU-AJ | 6 | 384g | LM35UU-OP | 5 | 335g | 35 | 0 -8μm | 0 -12μm |

| 40mm | LM40UU | 6 | 585g | LM40UU-AJ | 6 | 579g | LM40UU-OP | 5 | 500g | 40 | ||

| 50mm | LM50UU | 6 | 1580g | LM50UU-AJ | 6 | 1560g | LM50UU-OP | 5 | 1340g | 50 | ||

| 60mm | LM60UU | 6 | 1860g | LM60UU-AJ | 6 | 1820g | LM60UU-OP | 5 | 1610g | 60 | 0 -9μm | 0 -15μm |

| Major dimensions and tolerance | Eccentricity | Radial clearance (Max) | Basic load rating | ||||||||||||

| D | L | B | W | D1 | h | h1 | θ | ||||||||

| mm | Tolerance | mm | Tolerance | mm | Tolerance | Precision | High | Dynamic | Static | ||||||

| 15 | 0 -11μm | 24 | 0 -200μm | 17.5 | 0 -200μm | 1.1mm | 14.3mm | 1mm | - | - | 8μm | 12μm | -3μm | 274c N | 392cN |

| 19 | 0 -13μm | 29 | 22 | 1.3mm | 18mm | 1mm | 6.8mm | 80° | -4μm | 372c N | 549co N | ||||

| 21 | 30 | 23 | 1.3mm | 20mm | 1.5mm | 8mm | 80° | 510c N | 784co N | ||||||

| 28 | 37 | 26.5 | 1.6mm | 27mm | 1.5mm | 11mm | 80° | -6μm | 774c N | 1180co N | |||||

| 32 | 0 -16μm | 42 | 30.5 | 1.6mm | 30.5mm | 1.5mm | 11mm | 60° | 10μm | 15μm | 882c N | 1370co N | |||

| 40 | 59 | 0 -300μm | 41 | 0 -300μm | 1.85mm | 38mm | 2mm | 12mm | 50° | 980c N | 1570co N | ||||

| 45 | 64 | 44.5 | 1.85mm | 43mm | 2.5mm | 15mm | 50° | -8μm | 1570c N | 2740co N | |||||

| 52 | 0 -19μm | 70 | 49.5 | 2.1mm | 49mm | 2.5mm | 17mm | 50° | 12μm | 20μm | 1670c N | 3140co N | |||

| 60 | 80 | 60.5 | 2.1mm | 57mm | 3mm | 20mm | 50° | -10μm | 2160c N | 4020co N | |||||

| 80 | 100 | 74 | 2.6mm | 76.5mm | 3mm | 25mm | 50° | -13μm | 3820c N | 7940co N | |||||

| 90 | 0 -22μm | 110 | 85 | 3.15mm | 86.5mm | 3mm | 30mm | 50° | 17μm | 25μm | 4700c N | 10000co N | |||

Tips: How to Mount a Linear Ball Bearing

- Remove burrs, dirt and scratches on the mounting surface of the specific machine, and on the bearing's part, wash off the anti-rust oil on the surface by using cleaning oil. It’s important to note that the ball bushing could be vulnerable to rust without the protection of anti-rust oil, so it’s advised to apply lubricating oil to the spindle with lower viscosity.

- The table needs to be level during mounting, otherwise it will interfere with installation calibration. Gently place the linear ball bearing on the table, and engage the linear guide with the lateral mounting surface by using set screws or any other tools to tighten them up. (Make sure ahead of mounting that screw holes are consistent in case that the accuracy and performance of the units get diminished due to the forcible tightening of the inconsistent bolts. )

- Fasten the set screws of the linear bearing from the center to both sides to fit the track with the vertical mounting surface. By so doing, you can sustain the accuracy during operation.

- Use a torque wrench to lock every part accordingly , and tighten the set screws on the linear bearing slide rail.

- Mount the secondary rail in the same manner, and in some cases, you need to install the sliding seat on the main rail and the secondary rail. Note that after the sliding seat is installed on the linear sliding track, many subsequent accessories cannot be installed due to the limited installation space. Therefore, all the required accessories should be mounted before installing the sliding seat.

- Gently place the mobile platform on the sliding seats of the linear bearing main rail and the secondary rail, and then fasten the lateral compression screws on the platform, installation accomplished.

Notes:

- When pressing the linear ball bearing into the bearing pillow block, do not let the bearing outer surface, snap rings and sealing rings collide with the inner surface of the block. To prevent the bearing from deformation, you’d better use built-for-purpose tools and press in the bearing carefully.

- Do not put the bearing into the pillow block by twisting or else the bearing will get damaged.

- Keep axes parallel when incorporating the shaft into the linear bearing. Do not insert the shaft at a large angle into the bearing, otherwise the bearing will suffer reduction in accuracy and service life or worse still it may even cause steel balls to fall off.

- Reviews