- Stock: In Stock

- Model: SCJ006742

- SKU: SCJ006742

Available Options

Ask a Question About This Product

- Specifications

| Other attributes | |

| Condition | New |

| Place of Origin | Guangdong, China |

| warranty: | 1 Year |

| Applicable Industries: | Manufacturing Plant |

| Stroke Max. | 50mm |

| Power | Mechannial |

| Strip Width Max. | 100mm |

| Strip thickness Max. | 1.6mm |

| After-sales Service Provided | Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Engineers available to service machinery overseas |

| Usage | metal sheet strip coil |

| Machine Type | Pay-off Machine |

| Packaging and delivery | |

| Packaging Details | plywood box, plywood pallet. |

| Port | SHENZHEN |

| Supply Ability | |

| Supply Ability | 30 Set/Sets per Month |

- Description

High Speed Mechanical Roll Feeder

We are the leading the manufacturer and supplier of all type of Pneumatic Feeder such as Air Feeder, NC Servo Roll Feeder, Mechanical Gripper Feeder, New Gripper Series, CAM Feeder, Industrial Pneumatic Feeder, Heavy Duty Pneumatic Feeder, Gear Change Feeder, Gripper Feeder, High Precision Feeder, Nc Servo Feeder, Servo Roll Feeder, Push And Pull Feeder, Band Feeders, Coil Feeder, Mechanical Plunger Actuated Feeder, Zig Zag Feeders, Nc Servo Zig Zag Feeder, Mechanical Roll Feeder, Die Feeder, Roll Feeder, Zig Zag Feeders, Mechanical Plunger Actuated Feeder, Feeders For Power Press, Feeding Machine, Roll Feeder, Die Feeder, Coil Feeder.

High Speed Roller Feeder

1. High speed and high precision feeding, speed uptill to 600 stroke per minute.

2. Reliable and stable feeding

3. Durative: many project continuous processing is available

4. Fargoing using: to different width and thickness material, only need to adjust feeder to match mold

5. Compact structure, economical using

6. Low malfunction, easy maintenance

How To Select a Feeder?

Max. width of your strip in coil form ...mm

Max. stroke length of your feeding ...mm

Max. Min thickness of your strip ...mm

Max. Strokes per minute of press...

Specification:

Model | Strip Width (mm) | Stroke.Max(mm) | Strip Thickness (mm) | Material Line Height (mm) |

LH-105NS | 100 | 50 | 0-1.6 | 55-100 |

LH-205NS | 200 | 50 | 0-1.6 | 55-100 |

LH-255NS | 250 | 50 | 0-1.6 | 55-100 |

LH-305NS | 300 | 50 | 0-1.6 | 55-100 |

LH-405NS | 400 | 50 | 0-1.6 | 55-100 |

LH-505NS | 500 | 50 | 0-1.6 | 55-100 |

LH-605NS | 600 | 50 | 0-1.6 | 55-100 |

LH-138NS | 130 | 80 | 0-1.6 | 60-120 |

LH-1310NS | 130 | 100 | 0-3.5 | 70-140 |

LH-2010NS | 200 | 100 | 0-3.5 | 70-140 |

LH-1315NS | 130 | 150 | 0-3.5 | 70-140 |

LH-2015NS | 200 | 150 | 0-3.5 | 70-140 |

LH-5010NS | 500 | 150 | 0-3.5 | 70-140 |

LH-6015NS | 600 | 150 | 0-3.5 | 70-140 |

LH-1320NS | 130 | 200 | 0-3.5 | 70-140 |

LH-2020NS | 200 | 200 | 0-3.5 | 70-140 |

LH-7020NS | 700 | 200 | 0-3.5 | 70-140 |

LH-7030NS | 700 | 300 | 0-3.5 | 100-190 |

INTRODUCTION OF MACHINES

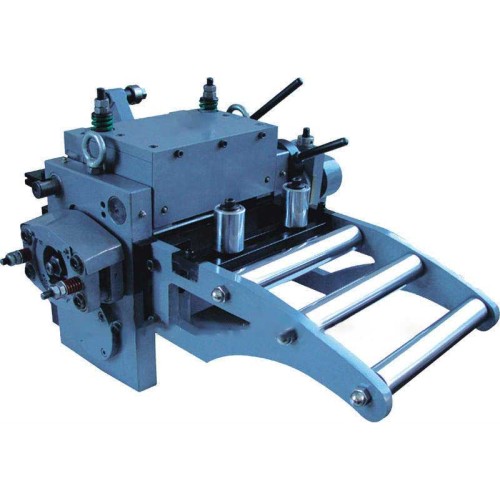

·Structures

The unitasis is assembled and all components are secured with high-strength screws. No welding parts, convenient for future repair and replacement of accessories, saving time and cost.

The left and right panels are made directly of liquid metal casting and are adaptable and can be used for a variety of alloy molding, flexibility is good.

The overall structure is compact, the occupied area is small, the installation is simple and convenient.

.

.

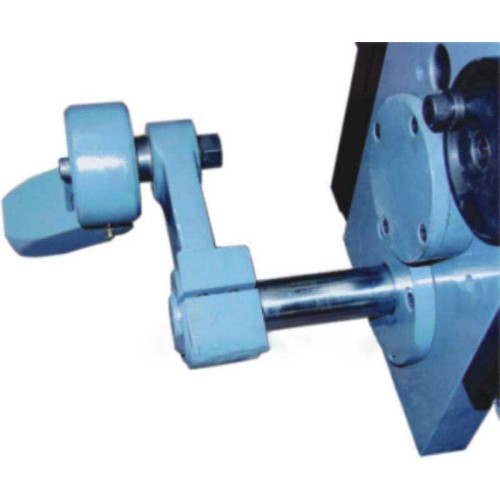

·Straigjtening roller

1. Corrective wheel is made of solid bearing steel, medium frequency after thickening electroplating treatment, surface hardness is not lower than HRC58 ensures that the material is durable.

2. Applies GCr15 forge round steel , after preheating (globeded annealing), followed by grinding, milling, After medium frequency treatment, coarse grinding cold stabilization, then fine grinding, and finally electroplating.Maximum assurance Precision, concentricity, finish and hardness, extend the service life of the corrective roller.

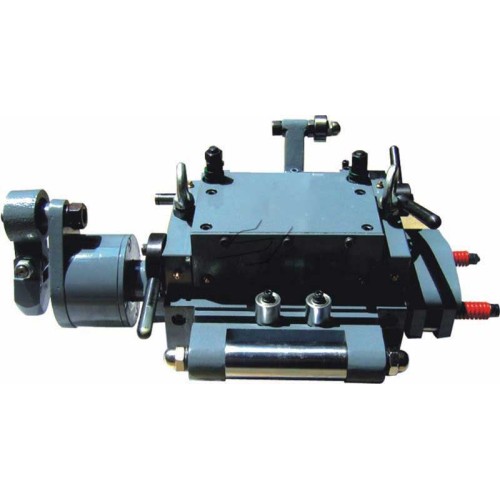

· Eccentric disc

Applies casting iron, adaptable, flexible, not easy to break.

The cross joint is compactand, with NSK imported bearings and runs smoothly without a cadon.

The scale wire rod is made of high-strength material for smooth adjustment Eccentric disc with multiple scales as a whole for easy adjustment

Pull rod

The mid-section of the pull rod is processed with a seamless tube and the material is highly hard.Two ends of the wire rod with round steel by the lathe finishing, to ensure that the processed workpiece in the middle section fixed tube fit to ensure stability during operation.The pull rod installation is easy to collect blood, two-way with double nuts for fixing, to prevent the two ends of the wire rod in the use of Increased safety due to long-term jitter in the process

- Reviews