- Stock: In Stock

- Model: SCJ009518

- SKU: SCJ009518

Available Options

Ask a Question About This Product

- Description

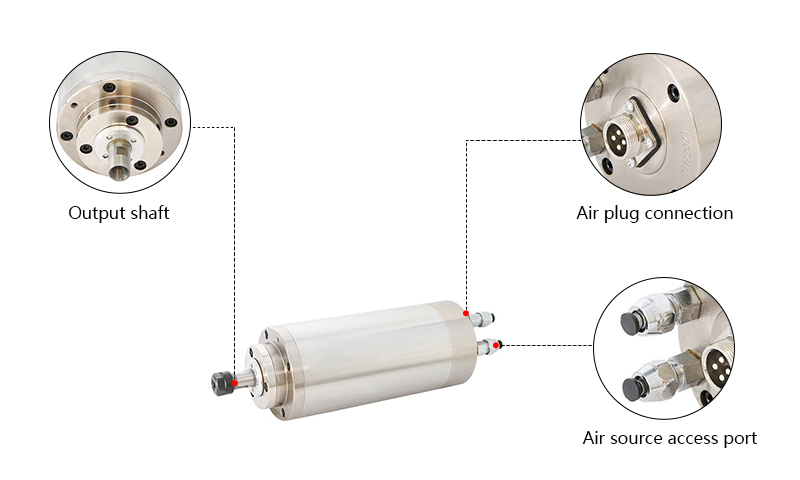

2.2 kW Water Cooled CNC Spindle Motor 24000 rpm ER20

Brief

Description

2.2 kW water cooled CNC spindle motor for sale at, 24000 rpm speed, 0.85 Nm torque, 400Hz frequency, 3 phase 220V/380V AC operating voltage, ER20 (φ3.175 mm - φ13 mm) collet.

Feature

- Spindle motor with superior durability ER20 collet ensures smooth running.

- Fast response, strong overload capacity, low noise and high mechanical precision.

- High quality 3 pcs bearings (7005Cx2 + 7002Cx1), runout off less than 0.01mm, tapered bore less than 0.005mm.

- P4 grade ceramic ball bearings used as spindle bearing, which improves the service life under high speed revolution.

- Lubricated with grease, which is resistant to 200 degrees high temperature.

- Tight sealing and two-layer dustproof design.

Application

This series water cooled electric spindle motors mainly match with variable frequency drives or engraving machines, CNC router machine, and used for high speed profiling, drilling, cutting, engraving and groove milling of wood, metal, plastics, foam, rubber and other materials.

Note: The spindle motor and VFD shall be suitable with each other. The specifications and parameter settings of the VFD shall match the nominal parameters of the spindle motor. Otherwise, it will burn the spindle motor if the settings are not correct.

Specification

| Model | STZ80-2.2-ER20 | |

| Power | 2.2 kW | |

| Diameter | φ80 mm | |

| Phase | Three phase | |

| Speed | 24000 rpm | |

| Voltage | 3-phase 380V±10% AC | 3-phase 220V±10% AC |

| Current | 4.2A | 8.0A |

| Matched VFD Model | GK3000-4T0037G (5 hp three phase VFD) | GK3000-4T0037G (5 hp three phase VFD) |

| Frequency | 400Hz | |

| Torque | 0.85 Nm | |

| Number of Pole | 2 poles | |

| Cooling Type | Water-cooled | |

| Installation Method | Horizontally or Vertically (When the motor is installed, the radial runout standard is required to be within 5um, and the chuck is generally 10um-15um.) | |

| Lubrication | Grease | |

| Thermal Class | Class F | |

| Protection Class | IP50 | |

| Certification | CE | |

| Warranty | Bearings for half a year, other parts for one year | |

| Joint of Nose | ER20 (φ3.175 mm - φ13mm) | |

| Bearings Type | 7005C P4*2 & 7002C P4*1 | |

| Application | Woodworking & Plastic | |

| Weight | 5 kg | |

| 2.2 kW Water Cooled Spindle Motor CAD Drawings | ||

Details

Tips: Spindle Motor Bearing Maintenance

We should check the quality of the bearings from time to time during the use of the spindle motor. Under what circumstances do the bearings of the spindle motor have to be replaced?

1. The high noise of the spindle motor may be because the bearing is broken. The bearing is the core component of the high-speed rotation of the spindle motor. The bearing has abnormal noise, which is the lack of oil in the bearing raceway. If the sound is a little loud, you can still use it. But at this time the spindle motor is working, you should pay attention to increase the circulating water volume to improve the cooling effect, try not to run for a long time, work for a period of time, you should stop to cool down.

2. If the spindle motor vibrates, do not continue to use it. On the one hand, it affects the machining accuracy. On the other hand, the motor vibrates, which indicates that the balls of the bearing have been severely worn, and it is easy to wear the bearing seat. Moreover, if you continue to use the motor at this time, it will easily cause the bearing to heat up, and the temperature will easily cause the bearing to stop operating and even burn the coil. In the case of the vibration of the spindle motor, it must be used with caution.

Safety Use

Safety Tips for Using SOCOJE CNC Spindle Motors

1. The electric spindle motor and VFD shall be suitable with each other. The specifications and parameter settings of the VFD shall match the nominal parameters of the spindle motor, and it will burn the spindle motor if the settings are not correct.

2. Before using water-cooled spindle motor, it shall ensure that cooling cycle system works normally and the running under no cooling conditions is prohibited. The volume of cooling water is calculated as per 1 liter/minute, the minimum flow of cooling water is not less than 5 liter/minute, cooling water pipe and the nozzle shall be connected reliably and there is no leakage.

3. The cooling liquid shall be clean and free of grease and the temperature shall be within 5-30℃. The cooling medium shall carry out force cooling when the ambient temperature is higher than 30℃. The precision lathe requires the cooling liquid with a constant temperature of 20 +/-2℃.

4. During storage and transport of the spindle motor, the status of high-speed grease inside the bearing will change. The user shall run it at a low speed first by starting from the lowest speed of the spindle motor for 30 minutes and then 20 minutes for every 3000 rounds. Otherwise there will have abnormal sound, noise, heat and other phenomena, which will affect the bearing life if the spindle motor is started directly at a high speed. During long term storage, the spindle motor shall run (at low speed) for 15-30 minutes once a week at last.

5. Collet, nut and inner taper hole shall be washed clean when installing blades on the spindle motor in order to avoid any impact on the precision. The blade handle shall be inserted into the collet more than 15mm.

6. For daily machining, the spindle motor shall be warmed up, run for 15-20 minutes when the machining speed is reached and then performs precise machining. It is better to stop the spindle motor for two hours every day in order to recover its mechanical fatigue and prolong its life time.

7. No knocking the end cover of the spindle motor. No hammering the collet and blade head when removing blades. No shocking or colliding during transport, storage and using, especially the end of the spindle motor.

8. The spindle motor shall run in designated direction.

9. The spindle motor shall be installed and fixed according to the relevant drawings and instructions.

10. The temperature shall be within 22-25℃ if water cooling machine is used.

11. The spindle motor adopts vapor lock and the gas source shall not be used until it has passed oil-water separator and dry filter. The air pressure is 0.2-0.25Mpa and the filtering precision is 5μm, otherwise there will cause damages to the bearing.

Documents

- Reviews