- Stock: In Stock

- Model: SCJ009268

- SKU: SCJ009268

Available Options

Ask a Question About This Product

- Description

1000 W DC Worm Gear Motor, 24V/48V

Brief

Description

1000W DC gear motor matches with worm gearbox providing high torque at 24V or 48V power supply, gear ratio from 7.5:1 to 100:1 available, high speed and high performance.

Specification

| Motor Model | SOCOJED110BLD1000-24A | SOCOJED110BLD1000-36A | SOCOJED110BLD1000-48A |

| Motor Type | BLDC Motor | ||

| Power | 1000W | ||

| Voltage | 24V DC | 36V DC | 48V DC |

| Rated Current | 52.08A | 34.72A | 26.04A |

| No Load Current | <12A | <8.5A | <6A |

| No Load Speed | 2700 rpm | ||

| Rated Speed | 2000 rpm | ||

| Rated Torque | 3.18N·m | ||

| Peak Torque | 9.54N·m | ||

| Motor Dimension | 110mm | ||

| Shaft Diameter | 11mm | ||

| Construction | Permanent Magnet | ||

| Direction of Rotation | CW/CCW | ||

| Certificate | CCC, CE, ROSH, LVD, EMC | ||

| Gear Ratio | 7.5, 10, 15, 20, 30, 40, 50, 60, 80, 100 | ||

| Recommended Drive Model | SCJ009268 | SCJ009268 | SOCOJE-BD50 |

| What Parameters of SOCOJE Worm Gear Motors Can Be Customized? | |||

| Power | Yes | ||

| Voltage | Yes | ||

| Speed | Yes | ||

| Shaft | Yes | ||

| Motor Length | Yes | ||

| Motor Lead | Yes | ||

Allowable Torque with Gear Head

| Gear Ratio | 7.5 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 |

| Rated Output Speed (rpm) | 267 | 200 | 133 | 100 | 80 | 67 | 50 | 40 | 33 | 25 | 20 |

| Rated Output Torque (Nm) | 28.7 | 38.2 | 57.3 | 47.5 | 90.7 | 106.0 | 133.7 | 124.0 | 94.0 | 115.0 | 87.0 |

Note:

- This torque value is the rated output value of the reducer, not the final motor + output torque value T after reducer.

- The formula for calculating the output torque after the final motor + reducer: T = rated torque of the motor * reduction ratio * 0.6, and T≤ rated allowable output torque value of the reducer.

Dimensions (Unit: mm)

Mounting screws are included with gearhead

Speed-Torque Curve

- Instantaneous maximum torque line

The maximum torque momentarily impacts the load when the motor is started.

Beyond this torque, the over-current protection of the driver will cause the motor to stop. - Short time operation area

The motor can run at a short time within this torque range at different speeds.

If the operation time is too long, the motor will generate heat, which may cause the motor to stop or burn. - Rated operating torque line

The rated torque of motor running at different speeds, and the motor can run for a long time at this torque. - Continuous operating area

When the motor rotates at different speeds, it runs continuously in this corresponding zone.

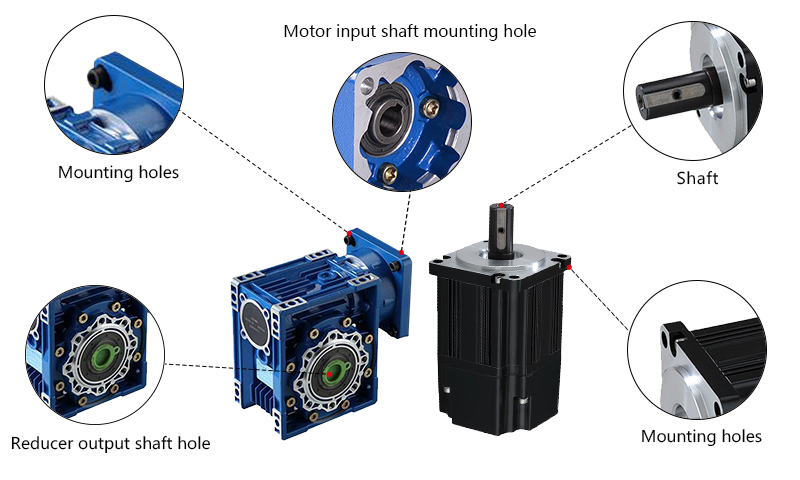

Details

Tips

The worm gear motor uses a worm gearbox to obtain a large transmission ratio, which is more compact than the cross-axis helical gear mechanism. The meshing tooth surfaces of the two wheels are in line contact, and its load-bearing capacity is much higher than that of the cross-axis helical gear mechanism. The worm drive is equivalent to a spiral transmission. It is multi-tooth meshing transmission, so the transmission is stable, the noise is low, and it has self-locking. When the lead angle of the worm is smaller than the equivalent friction angle between the meshing gear teeth, the mechanism has self-locking property and can realize reverse self-locking, that is, the worm shaft can only be driven by the worm, but the worm cannot be driven by the worm shaft. For example, the self-locking worm mechanism used in hoisting machinery, its reverse self-locking property can play a safety protection role. The transmission efficiency is low and the wear is more serious. When the worm gear is engaged for transmission, the relative sliding speed between the meshing gear teeth is large, so the friction loss is large and the efficiency is low. On the other hand, the relative sliding speed means that the tooth surface wears severely and generates heat. In order to dissipate heat and reduce wear, more expensive materials with better anti-friction and anti-wear properties and good lubricating devices are often used, so the cost is higher. The axial force of the worm is larger.

- Reviews