90 W DC Gear Motor, 3000 rpm, 12V/24V/48V

from

$193.25

Ex Tax: $193.25

- Stock: In Stock

- Model: SCJ009273

- SKU: SCJ009273

Products Sold: 0

Product Views: 855

Available Options

Ask a Question About This Product

- Description

90 W DC Gear Motor, 3000 rpm, 12V/24V/48V

Brief

The offered gear motor is a 90W brushless DC motor with a 90 mm size gearbox fitted to the front of the motor. The DC motor with rated speed of 3000 rpm, rated torque of 0.29 Nm, peak torque up to 0.86 Nm, 12V, 24V, 48V voltage for you to choose from.

Description

Low cost 90W DC gear motor with 3000 rpm rated speed, 9.38A rated current at 12V, 4.69A at 24V, 2.34A at 48V, 3:1 to 200:1 gear ratio are available here. This small DC gear motor suitable for a lot of industrial applications such as food processing machine, sealing equipment, textile machine etc..

90W DC gear motor specifications

| Model | SCJ009273 | SOCOJED5BLD90-24 | SOCOJED5BLD90-48 |

| Power | 90W | 90W | 90W |

| Voltage | 12V | 24V | 48V |

| Rated Speed | 3000 rpm | 3000 rpm | 3000 rpm |

| No-load Speed | 3300 rpm | 3300 rpm | 3300 rpm |

| Rated Current | 9.38A | 4.69A | 2.34A |

| Rated Torque | 0.29 N.m | 0.29 N.m | 0.29 N.m |

| Peak Torque | 0.86 N.m | 0.86 N.m | 0.86 N.m |

| No-load Current | < 0.85A | < 0.7A | < 0.5A |

| Compatible Driver Model | BLD-300B (Click it to the product page) | BLD-120A (Click it to the product page) | |

| Weight | 2.3 Kg | ||

| Protection Grade | IP54 | ||

| Motor Lead Length | 300mm | ||

| Temperature | 0~50℃ | ||

| Gearbox Model | 2GN□K Enter the gear ratio into the box (□) within the model name | ||

| Gear Ratio | 3, 5, 7.5, 10, 12.5, 15, 18, 20, 25, 30, 36, 40, 50, 60, 75, 90, 100, 120, 150, 180, 200 | ||

Note: Motor length, power, voltage and speed can be customized according to your requirements under the allowed circumstance of adoptable dimension.

The allowable torque with a gearbox

| Gear Ratio | 3 | 5 | 7.5 | 10 | 12.5 | 15 | 18 | 20 | 25 | 30 | 36 | 40 | 50 | 60 | 75 | 90 | 100 | 120 | 150 | 180 | 200 |

| Speed (r/min) | 1000 | 600 | 400 | 300 | 240 | 200 | 167 | 150 | 120 | 100 | 83.33 | 75 | 60 | 50 | 40 | 33 | 30 | 25 | 20 | 17 | 15 |

| Allowable Torque (N.m) | 0.67 | 1.16 | 1.74 | 2.32 | 2.61 | 3.14 | 3.77 | 3.78 | 4.73 | 5.67 | 6.81 | 7.56 | 9.46 | 11.35 | 14.18 | 15.21 | 16.9 | 20 | 20 | 20 | 20 |

| Allowable Torque (kgf.cm) | 6.96 | 11.6 | 17.4 | 23.21 | 26.14 | 31.37 | 37.65 | 37.82 | 47.27 | 56.73 | 68.07 | 75.64 | 94.55 | 113.5 | 141.8 | 152.1 | 169 | 200 | 200 | 200 | 200 |

Note:

- The values colored "Red" indicate that the gearbox and the DC motor are running in the same direction, and the other values are in the opposite direction.

- When it is desired to reduce the speed further than the gear ratio in the table above, an intermediate speed reducer with a gear ratio of 10 can be installed between the motor and the gearbox.

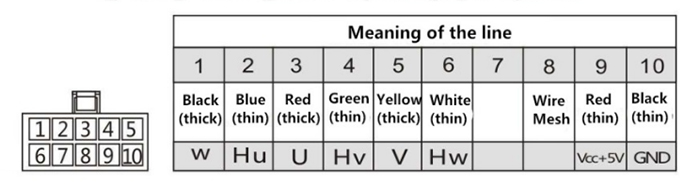

Wiring Definition

Dimension (Unit: mm)

*Mounting screws are included with gearbox

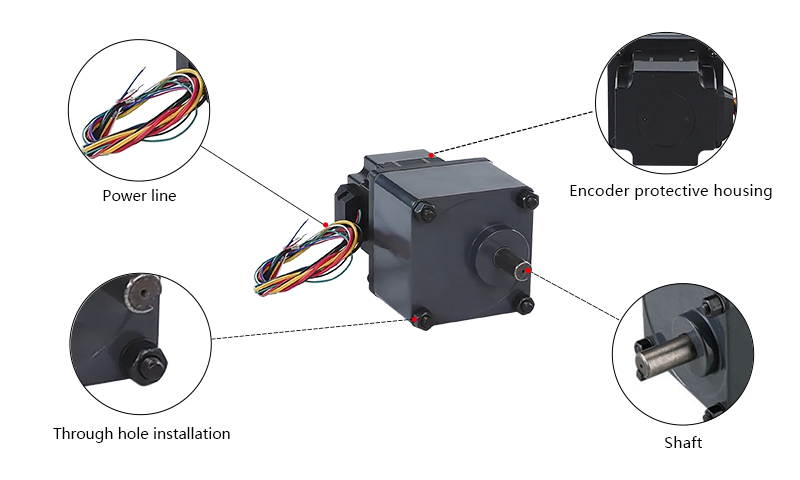

Details

Tips: Why does the gear motor vibrate?

- Armature imbalance. Due to the centrifugal force generated by the unbalanced mass during rotation, a rotational force acts on the bearing, causing vibration of the motor. When the air gap is uneven, the main engine is not tightly fixed, or the rigidity of the base and the end cover is poor, vibration will be aggravated. Therefore, if the rotor is found to be unbalanced during the inspection, it must be rebalanced.

- The radial clearance of the bearing is too large, and the outer ring and the end cover loosen together. When assembling, the bearings should be inspected. Bearing and journal, bearing seat must meet the requirements, otherwise it must be sprayed or brushed to deal with the process, to avoid bearing vibration caused by poor. For worn bearings, the frequency of vibration and noise during the operation of the motor is relatively high and it is easy to judge. In this case, bearings should be replaced.

- Manufacturing error or deformed operation of the seat, end cover and other important braces. The shape and position error on the fitting surfaces of seat, end cover and other important rotor braces, particular the deformation of important braces (such as seat, end cover) of large and medium motors after long-term operation, make the bearing to produce an interference force, thus leading to the motor vibration.

- Reviews