Hydraulic Orbital Motor 125cc/rev low speed high torque

from

$219.75

Ex Tax: $219.75

- Stock: In Stock

- Model: SCJ009558

- SKU: SCJ009558

Products Sold: 0

Product Views: 550

Available Options

Ask a Question About This Product

- Description

Hydraulic Orbital Motor 125cc/rev low speed high torque

Brief

Factory price hydraulic orbital motor online sale, low speed high torque with 125cc/r displacement. It is a spool valve motor can be used in parallel or series, selectable flat key shaft or splined shaft, mounting flanges of 2 bolts and 4 bolts.

Description

hydraulic orbital motor with high performance shaft, can bear high pressure, high speed and high radial force. Mounting flanges of 2 bolts and 4 bolts, easy to install.

Specification

| Model | SCJ009558 | |

| Shaft Type (Optional) | Flat Key, Splined | |

| Flange Type (Optional) | 2 Bolts, 4 Bolts | |

| Displacement | 125 cc/rev (125 cm3/rev) | |

| Working Pressure | 15 MPa | |

| Flow | Continuous | 57 LPM |

| Intermittent | 68 LPM | |

| Max.Speed | Continuous | 452 rpm |

| Intermittent | 544 rpm | |

| Pressure | Continuous | 124 ∆Bar |

| Intermittent | 138 ∆Bar | |

| Torque | Continuous | 194 Nm |

| Intermittent | 216 Nm | |

| Weight | 7.5kg | |

Note:

- A simultaneous maximum torque and maximum speed is not recommended.

- ∆Bar refers to true pressure difference between inlet port and outlet port.

- Continuous Rating means that the motor may be run continuously at these ratings.

- Intermittent operation refers to that the motor running time must not exceed 10% per minute under this condition.

*To assure best orbital motor life, run it for approximately one hour at 30% of rated pressure before application to full load. Be sure this motor is filled with fluid prior to any load applications.

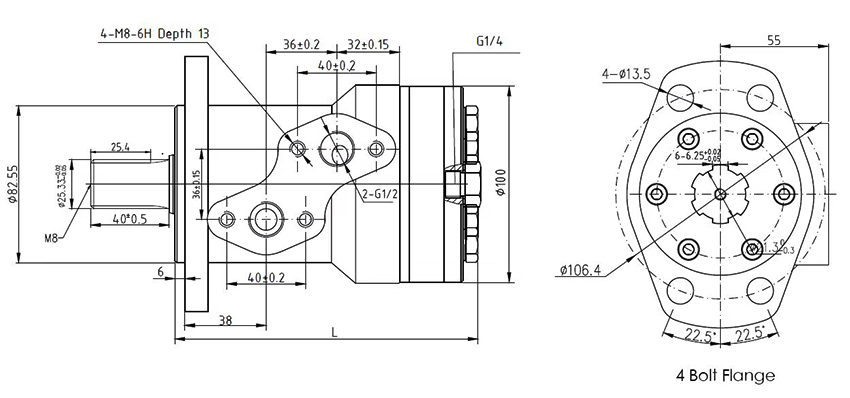

Dimensions (Unit: mm)

L1=154mm

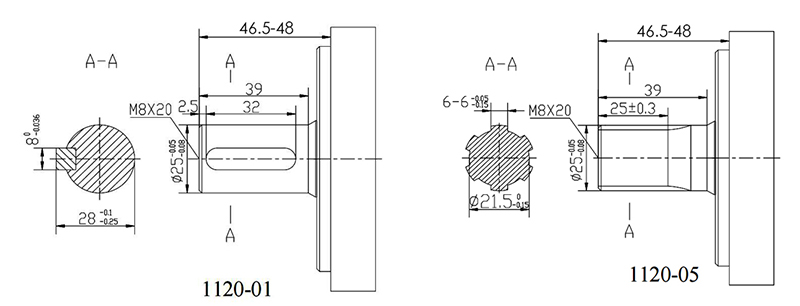

Hydraulic Orbital Motor Shaft (Unit: mm)

Flange Types (Unit: mm)

L=160mm

Details

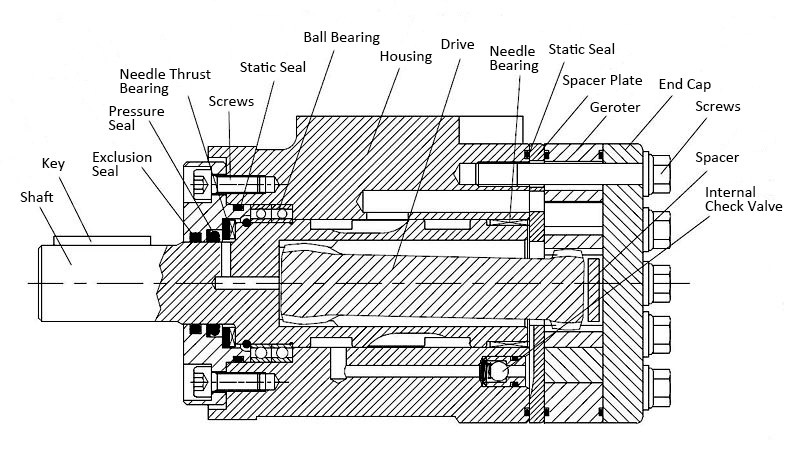

Tips: Main features of hydraulic orbital motors

- The hydraulic orbital motor adopts end face flow distribution and axial face flow distribution. Its structure is simple and compact, and the flow distribution accuracy is high.

- The hydraulic orbit motor adopts toothed stator and rotor pair, high mechanical efficiency, long service life under high pressure.

- It adopts double-joint angular ball bearings, which can bear larger radial and axial loads, with low friction and high mechanical efficiency.

- The advanced flow distribution mechanism design has the characteristics of high flow distribution accuracy and automatic wear compensation.

- These motors are allowed to be used in series and in parallel, and the external drain port should be connected when used in series.

- The tapered roller bearing support design has a large radial load capacity, so that the motor can directly drive the working mechanism.

- It has a variety of installation and connection forms such as flanges, output shafts, and oil ports.

- Reviews