- Stock: In Stock

- Model: SCJ009334

- SKU: SCJ009334

Available Options

Ask a Question About This Product

- Description

Nema 17 Stepper Motor Linear Actuator, 2 phase, 4V, 0.95A

Brief

Description

2 phase 4V, 0.95A Nema 17 Stepper Motor Linear Actuator with higher performance and lower cost. To meet the needs of a wide range of linear motion applications, two stepper motor linear actuator styles are available:

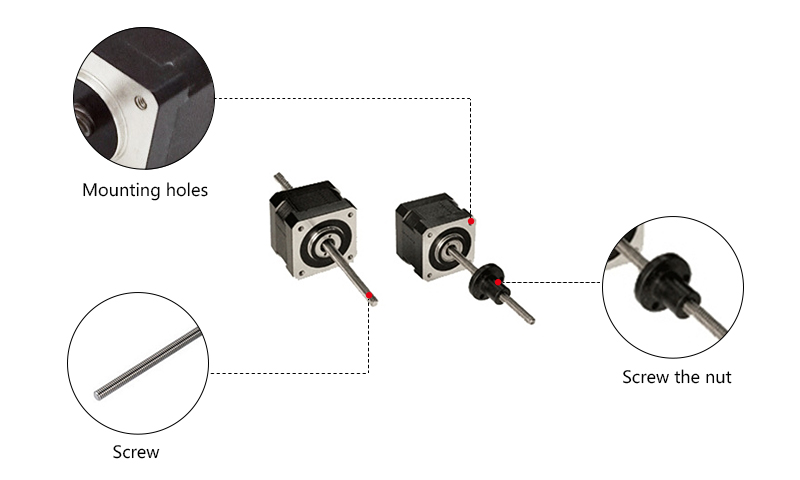

Non-captive shaft has a threaded shaft that extends through the motor and moves axially as the motor rotates.

External shaft has a rotating screw, integral to the motor's rotor, that moves the nut axially along the threaded shaft.

Stepper Motor Linear Actuator Specification

| Model Type | External Shaft | Non-Captive Shaft |

| 42H33-0956AST | 42H33-0956GTS | |

| Weight | 4 kg | |

| Length | 33 mm | |

| Phase | 2 phase | |

| Step Angle | 1.8° | |

| Rated Voltage | 4 V | |

| Rated Current | 0.95 A | |

| Resistance | 4.2 Ω | |

| Holding Torque | 22 Oz-in | |

| Number of Leads | 6 | |

| Rotor Inertia | 35 g-cm2 | |

Select Leadscrew

Choose your stepper motor linear actuator screw from one of the available options:

| Screw Diameter | Lead | Travel Per 1.8 Step | |||

| (in) | (mm) | (in/rev) | (mm/rev) | (in/step) | (mm/step) |

| 0.315 | 8 | 0.079 | 2 | 0.00039 | 0.01 |

| 0.315 | 8 | 0.157 | 4 | 0.00079 | 0.02 |

| 0.315 | 8 | 0.315 | 8 | 0.00157 | 0.04 |

| Note: Screw of 8mm diameter is made of copper. | |||||

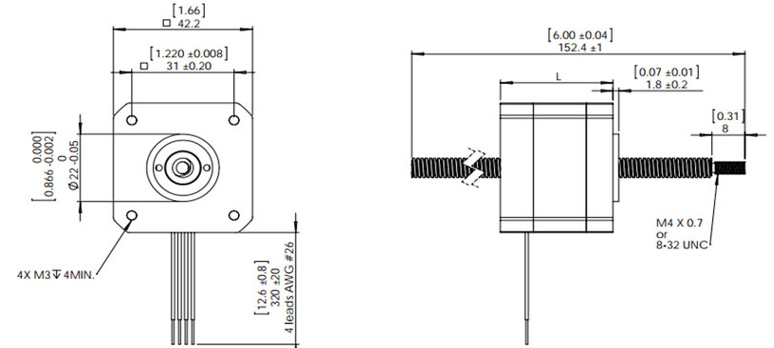

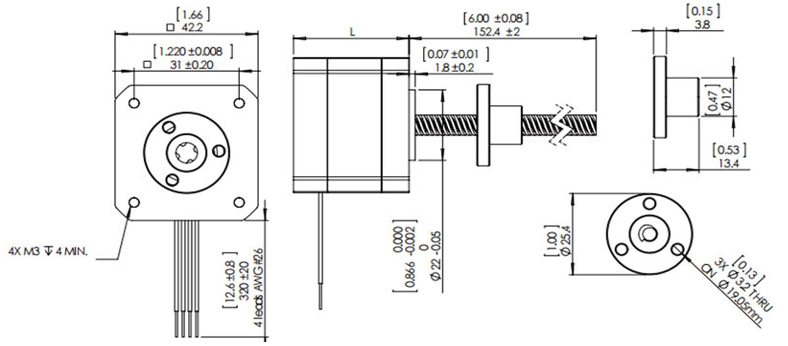

Stepper Motor Linear Actuator Dimension (Unit=mm)

1. Non-captive shaft style

L=33mm

2. External shaft style

L=33mm

Details

Tips: Screw Pitch of stepper motor linear actuator

The step length of linear screw stepper motor depends on the step angle and pitch between the interoperable internal thread nut and lead screw. The steep-pitch thread produces larger step length than the small pitch thread. However, for a given stepping rate, small pitch thread can provide greater propulsive force. When the motor is out of power, steep-pitch thread can easily be driven in the opposite direction while the small pitch thread cannot. There must be a certain degree of freedom the rotor and the screw in order to guarantee the high work efficiency, which requires a certain gap between them, about 0.03 to 0.08 mm axial gap (also called reverse gap). Generally, the larger the helical pitch is, the larger the gap is.

- Reviews