- Stock: In Stock

- Model: SCJ009419

- SKU: SCJ009419

Available Options

Ask a Question About This Product

- Description

Nema 17 Stepper Motor, 2 Phase, 1.8A, 0.5N·m

Brief

Description

Nema 17 bipolar stepper motor is a permanent magnet electric motor that converts electrical pulse signal into corresponding angular displacement or linear displacement. It is widely used in electronics manufacturing, semiconductor equipment, laser cutting, textile machinery and so on.

Physical Specification

- Model Number: SOCOJE-FY42EL180A

- Matched the Driver Model: SOCOJE-FYQM302A

- Flanged Size: 42 x 42mm (Nema 17)

- Motor Length: 48mm

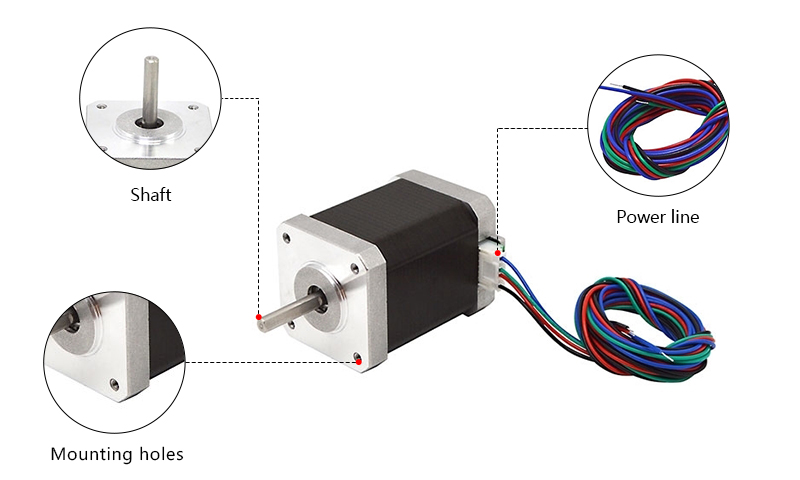

- Shaft Diameter: 5mm

- Number of Leads: 4 wire

- Weight: 0.35kg

Electrical Specification

- Motor Type: Bipolar Stepper

- Step Angle: 1.8°

- Rated Current: 1.8A

- Holding Torque: 0.5 N·m (50 N·cm, 71 Oz.in)

- Phase Resistance: 1.8Ω

- Phase Inductance: 3.2mH

- Rotor Inertia: 68g·cm2

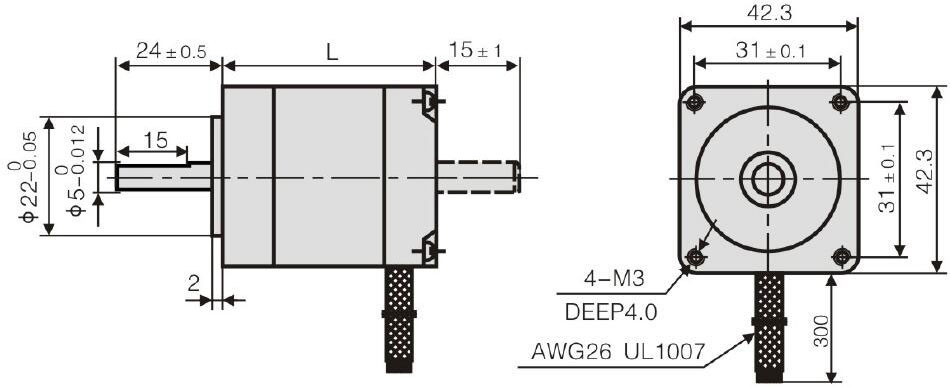

Dimensions (Unit: mm)

L=48mm

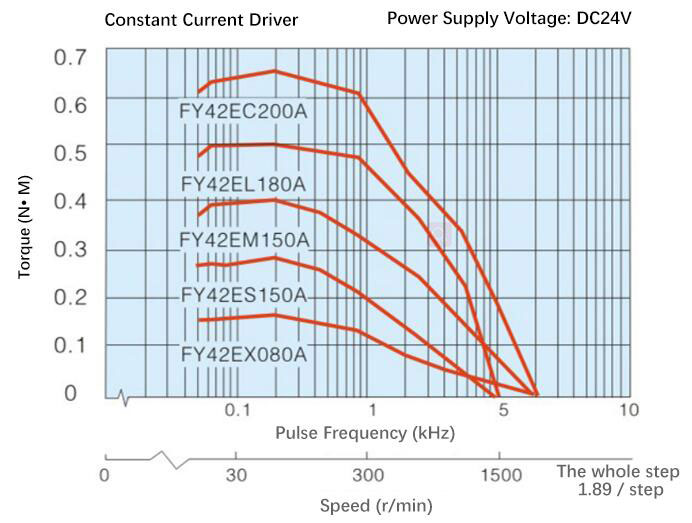

Speed-Torque Curve Diagram

Details

Tips: How does PLC control the stepper motor?

PLC can realize the control of the stepper motor by its high speed pulse output function or motion control function. The stepper motor is a kind of electric hybrid motor with low rotor inertia, high positioning accuracy, small errors and simple control. It is one of the main actuators in the field of motion control. As an industrial control computer, PLC has a modular structure, flexible configuration, high-speed processing speed, accurate data processing capabilities, multiple control functions and network technology performance. It is currently one of the most widely used control devices, so PLC is very advantageous to control the operation of the stepper motor.

The start frequency, stop frequency and output torque of the best stepper motor must be adapted to the moment of inertia of the load. However, if PLC is used to control the stepper motor, the pulse equivalent, the upper limit of pulse frequency and the maximum number of pulses of the system should be calculated according to the following formula, and then the PLC and its corresponding functional modules should be selected. According to the pulse frequency, the frequency required for high-speed pulse output of the PLC can be determined, and the bit width of the PLC can be determined according to the number of pulses.

Documents

- Reviews