- Stock: In Stock

- Model: SCJ009370

- SKU: SCJ009370

Available Options

Ask a Question About This Product

- Description

Nema 34 Bipolar Stepper motor, 6A, 2 phase 4 wires, 12Nm

Brief

Description

The Nema 34 stepper motor is a professional and high precision stepper motor with 1.8 deg. step angle (200 steps/revolution), 2 phase 4 wires, high holding torque of 12Nm, each phase draws current 6A.

Specifications

| Basics | Model | SOCOJE2160-6004A |

| Matched the Driver Model | SCJ009370 (Click it to see more info) | |

| Step Angle | 1.8° | |

| Length | 160mm | |

| Weight | 5.5kg | |

| Current | 6A | |

| Resistance | 0.7Ω | |

| Holding Torque | 12Nm | |

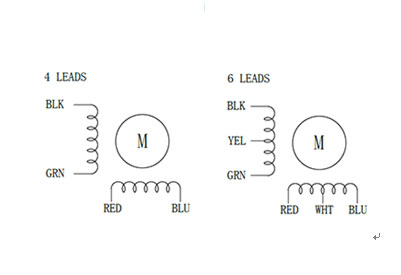

| Motor Leads | 4 | |

| Rotor Inertia | 4800g-cm2 | |

| Technical parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃Max. (rated current, 2 phase on) | |

| Ambient Temperature | -10℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 1Min. 500VAC·5mA | |

| Shaft Radial Play | 0.06Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g |

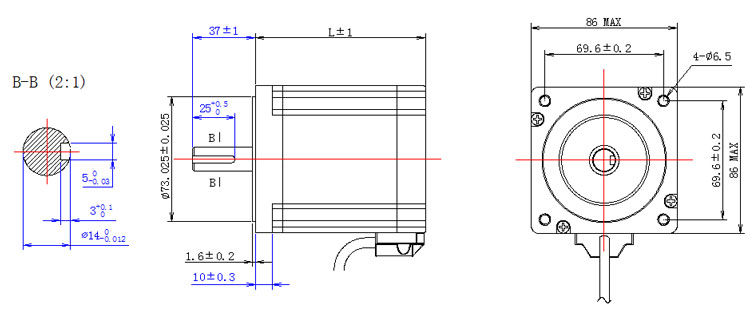

Dimension

Motor Connection

Tips: Reasons and solutions for reduction in torque frequency characteristic of the stepper motor

The relationship between output torque and control pulse of stepper motor is called torque frequency characteristic.

Feature: By taking the maximum load torque (start torque), the rotational velocity of the stepper motor will be increased gradually but the load capacity is reduced along with the increase in pulse frequency.

The reasons for the reduction in torque frequency characteristic of the stepper motor:

- Influence of winding inductance: It takes certain time to rise and reduce the current in winding. When the pulse frequency is low, it can realize long power-on cycle of winding, large average value of current, high energy that can be obtained for the motor and high torque that can be maintained. However, when the pulse frequency is high, it can realize short power-on cycle of winding, small average value of current, little energy that can be obtained for the motor and reduction in torque that can be maintained.

- Iron loss: Along with the rising frequency, the rotational velocity of the rotor is increased. Due to additional rotational EMF generated in rotor winding, the motor faces larger resistance torque and the eddy loss of iron core is also increased.

Measures for improving the high frequency of torque characteristic through two ways:

- Resistance can be increased by reducing the time constant. To ensure the current in live current is not changed, it is also necessary to increase the power voltage while increasing the resistance.

- Improve working mode. Adopt multi-phase exciting working mode. Due to the multi-phase exciting working mode, the power-on time for each phase is prolonged, then more energy can be obtained for the motor so that the output torque is increased.

- Reviews