Nema 17 Stepper motor, 2.8V 1.33A, 1.8 degree, 2 phase 4 wires

from

$64.92

Ex Tax: $64.92

- Stock: In Stock

- Model: SCJ009425

- SKU: SCJ009425

- UPC: 747851311410

Products Sold: 0

Product Views: 659

Available Options

Ask a Question About This Product

- Description

Nema 17 Stepper motor, 2.8V 1.33A, 1.8 degree, 2 phase 4 wires

Brief

2.8V, 1.33A, 30 oz-in NEMA 17 stepper motor, 4 wires bipolar stepper motor with 1.8 degree step angle, produce a maximum torque of 2.2 kg-cm, brand new direct sale by manufacturer.

Description

Nema 17 stepper motor, 2.8V 1.33A, 2 phase 4 wires bipolar stepper motor with 1.8 degree step angle, small body in 33mm, perfect for all kinds of mechanical and robotics projects.

Specifications

| Electrical Specification | Model | SOCOJE33-1334A |

| Matched the Driver Model | SCJ009425 (Click it to see more info) | |

| Step Angle | 1.8° | |

| Holding Torque | 2.2kg-cm(30Oz-in) | |

| Voltage | 2.8V | |

| Rated Current/phase | 1.33A | |

| Phase Resistance | 2.1Ω | |

| Inductance | 4.2mH | |

| Rotor Inertia | 35g-cm2 | |

| Physical Specification | Frame Size | 42 x 42mm |

| Length | 33mm | |

| Shaft Diameter | Φ5mm | |

| Shaft Length | 22mm | |

| Motor Leads | 4 | |

| Weight | 0.22kg | |

| Technical Parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max. (rated current, 2 phase on) | |

| Ambient Temperature | -10℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 1Min. 500VAC·5mA | |

| Shaft Radial Play | 0.06Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g | |

| Quality Assurance | Warranty Period | 12 months |

| Certificate | CE, ROHs, ISO/SGS9001 |

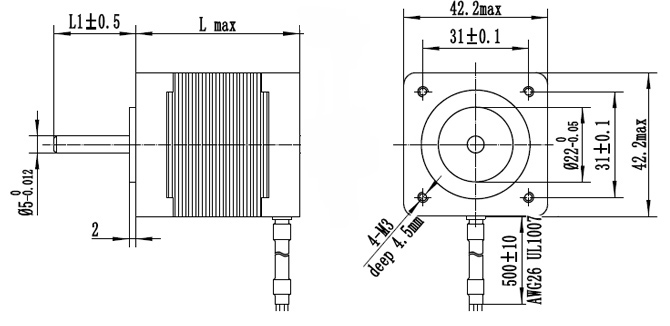

Nema 17 Stepper Motor Dimension (Unit=mm)

L1=24mm, Lmax=33mm

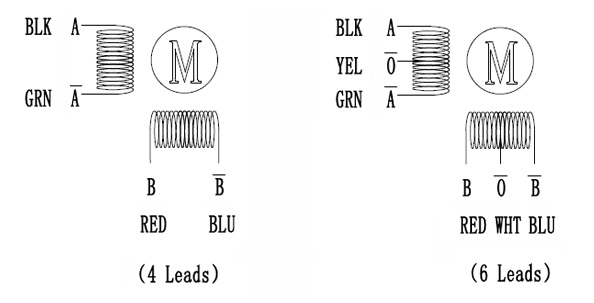

Nema 17 Stepper Motor Wiring Diagram

Tips: How to overcome the vibration and noises of 2-phase hybrid stepper motor when rotating at low velocity?

The vibration and noise of the stepper motor rotating at low velocity its the intrinsic defects, which can be generally overcome by adopting following schemes:

- If the stepper motor works at resonance region, the resonance region can be evaded by changing mechanical transmissions such as velocity ratio.

- Use subdivided driver, which is the most common and simple method.

- Replace for the stepper motor with smaller stepping angle, like 3-phase or 5-phase stepper motor.

- Replace for AC servo motor, which can nearly overcome vibration and noise, but the cost is quite high.

- Add magnetic damper to the shaft of motor, such product has been available in the market, but the mechanical structure is changed a lot.

- Reviews