Nema 17 Stepper Motor Linear Actuator, 2 phase, 6V, 0.8A

from

$132.23

Ex Tax: $132.23

- Stock: In Stock

- Model: SCJ009336

- SKU: SCJ009336

Products Sold: 0

Product Views: 508

Available Options

Ask a Question About This Product

- Description

Nema 17 Stepper Motor Linear Actuator, 2 phase, 6V, 0.8A

Brief

2 phase 6 wires, 0.8A 6V stepper linear actuator with a 1.8 degree Nema 17 stepper motor and a 152mm length precision lead screw, is ideal for applications requiring a combination of precise positioning, rapid motion and long life.

Description

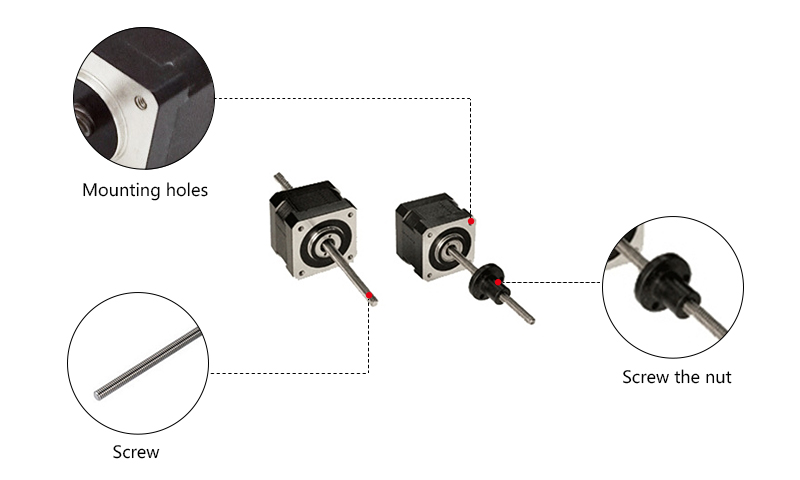

This Nema 17 Stepper Motor Linear Actuator can dramatically reduce cost and save space. Two versions can be delivered:

1. Non-Captive shaft stepper linear actuator with nut inside motor. Linear moving part can rotate so it should be fixed.

2. External shaft stepper linear actuator. Nut are mounted on lead screw.

Stepper Motor Linear Actuator Specification

| Model Type | External Shaft | Non-Captive Shaft |

| 42H47-0806AST | 42H47-0806GTS | |

| Weight | 4 kg | |

| Length | 47 mm | |

| Phase | 2 phase | |

| Step Angle | 1.8° | |

| Rated Voltage | 6 V | |

| Rated Current | 0.8 A | |

| Resistance | 7.5 Ω | |

| Holding Torque | 44 Oz-in | |

| Number of Leads | 6 | |

| Rotor Inertia | 68 g-cm2 | |

Select Leadscrew

Choose your stepper motor linear actuator screw from one of the available options:

| (in) | (mm) | (in/rev) | (mm/rev) | (in/step) | (mm/step) |

| 0.315 | 8 | 0.079 | 2 | 0.00039 | 0.01 |

| 0.315 | 8 | 0.157 | 4 | 0.00079 | 0.02 |

| 0.315 | 8 | 0.315 | 8 | 0.00157 | 0.04 |

| Note: Screw of 8mm diameter is made of copper. | |||||

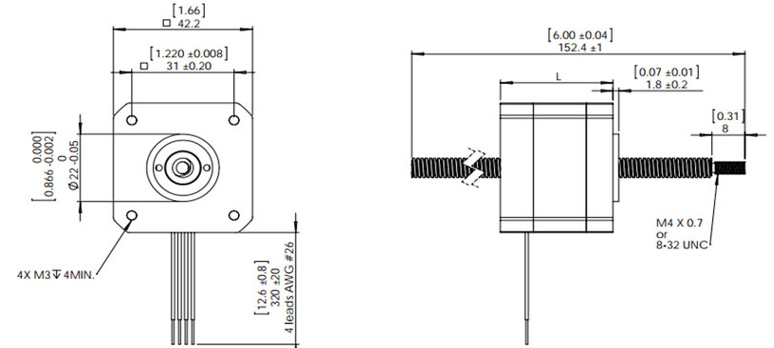

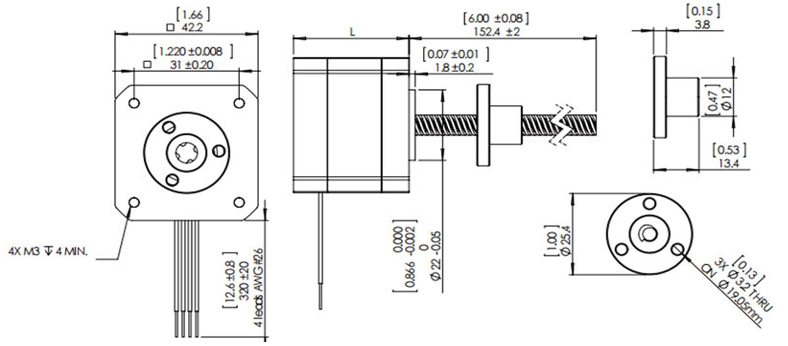

Stepper Motor Linear Actuator Dimension (Unit=mm)

1. Non-captive shaft style

L=47mm

2. External shaft style

L=47mm

Details

4 tips for stepper motor linear actuator applications

- The stepper motor linear actuator is generally applied to the low speed situation with a speed of no more than 1000 rpm. It should work during this period through speed reducer. At this time, the work efficiency of the motor is high and the noise is at the low frequency state.

- Usually it is suggested that it is better not to use the whole step state of the stepper motor linear actuator because the vibration in the whole step state is large, and it is not suitable for long time operation and is easy to reduce the loss of service life.

- The motor with large seated number should be selected in load with large rotary inertia.

- When the motor is at a high speed or in a large inertia load, it usually does not start at the working speed but uses a gradual increase in speed and frequency. In a high precision state, a mechanical deceleration should be carried out to improve the speed of the motor, or a driver with high fine fraction should be used to solve the problem.

- Reviews