Nema 23 2-phase Stepper Motor, 2A, 1.8 degree, 6 wires

from

$65.46

Ex Tax: $65.46

- Stock: In Stock

- Model: SCJ009403

- SKU: SCJ009403

Products Sold: 0

Product Views: 755

Available Options

Ask a Question About This Product

- Description

Nema 23 2-phase Stepper Motor, 2A, 1.8 degree, 6 wires

Brief

Low cost and high quality stepper motor, 2A, 1.35Nm holding torque, 1.8 deg. step angle(200 steps/rev), size in Nema 23, brand new and manufacturer direct sale.

Description

Nema 23 Stepper motor, 1.35Nm in 76mm, 1.8 degree, 2 phase 6 wires.

Specification

| Electrical Specification | Model | SOCOJE57STH76-2006 |

| Matched Driver Model | SCJ009403(Click it to see more info) | |

| Step Angle | 1.8° | |

| Holding Torque | 1.35Nm | |

| Rated Current/phase | 2A | |

| Phase Resistance | 2.25Ω | |

| Inductance | 3.6mH | |

| Rotor Inertia | 440g-cm2 | |

| Physical Specification | Frame Size | 57 x 57mm |

| Length | 76mm | |

| Shaft Diameter | Φ6.35mm | |

| Shaft Length | 19mm | |

| Motor Leads | 6 | |

| Weight | 1.1kg | |

| Technical Parameters | Step Angle Accuracy | ±5% (full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max. (rated current, 2 phase on) | |

| Ambient Temperature | -20℃~+50℃ | |

| Insulation Resistance | 100MΩ Min. 500VDC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.02Max. 450g | |

| Shaft Axial Play | 0.08Max. 450g | |

| Quality Assurance | Warranty Period | 12 months |

| Certificate | CE, ROHs, ISO/SGS9001 |

Nema 23 Stepper Motor Dimensions: (Unit=mm)

L Max=76mm

L Max=76mm

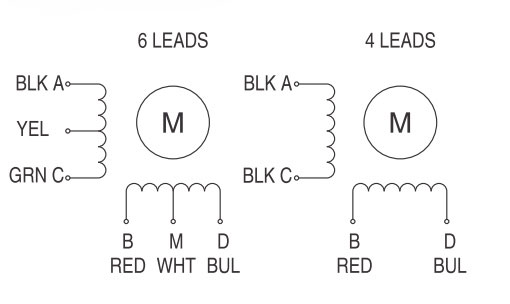

Nema 23 Stepper Motor Wiring Diagram

Tips: Advantages and disadvantages of stepper motor

A. Advantages

- The rotational angle of motor is in direct proportion to number of pulses.

- The torque is the largest when the motor stops rotating (when winding is excited).

- As the precision of each step is 3% to 5% and the error at one step will not be accumulated to the next one, so there is good position accuracy and repeatability of motion.

- Excellent start and stop and inversion response.

- Without electric brush, the reliability is high. Therefore, the service life of motor only depends on that of bearing.

- The response of motor is determined by the digital input pulse, so open-loop control can be adopted. As a result, the structure of the motor can be simple and the cost can be controlled.

- Synchronous rotation at extremely low velocity by only directly connecting the load to the spindle of motor.

- For the velocity is in direct proportion to the pulse frequency, there is wide range of rotational velocity.

B. Disadvantages

- If not controlled properly, the resonance can be easily caused.

- Hard to rotate at high rotational velocity.

- Hard to obtain large torque.

- No advantage over volume and weight and low utilization ratio of energy resources.

- Reviews