Nema 24 Stepper Motor, 2A, 1.8 degree, 2 phase 4 wires

from

$84.62

Ex Tax: $84.62

- Stock: In Stock

- Model: SCJ009383

- SKU: SCJ009383

Products Sold: 0

Product Views: 838

Available Options

Ask a Question About This Product

- Description

Nema 24 Stepper Motor, 2A, 1.8 degree, 2 phase 4 wires

Brief

High quality Nema 24 stepper motor with 1.8 deg. step angle(200 steps/rev). Each phase draws current 2A, allowing for a holding torque of 2.5Nm.

Description

Nema 24 Stepper motor, 1.8 degree, 2.5Nm in 88mm, phase current 2A and resistance 1.2Ω.

Specification

| Basics | Model | SOCOJE288-2004A |

| Matched Driver Model | SCJ009383(Click it to see more info) | |

| Holding torque | 2.5Nm | |

| Current/phase | 2A | |

| Resistance | 1.2Ω | |

| Step angle | 1.8° | |

| Rotor inertia | 1600g.cm² | |

| Weight | 2.4kg | |

| Length | 88mm | |

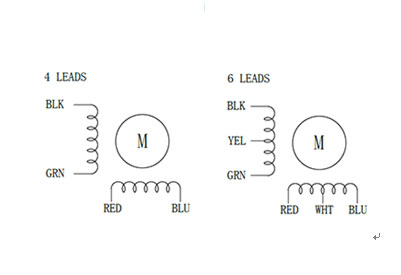

| Motor leads | 4 | |

| Technical parameters | Step Angle Accuracy | ±5%(full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max.(rated current, 2 phase on) | |

| Ambient Temperature | -10℃~+ 50℃ | |

| Insulation Resistance | 100MΩ Min 500V DC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.06Max.(450g) | |

| Shaft Axial Play | 0.08Max.(450g) |

Dimensions

Motor Connection

Tips: Application of stepper motor in material measurement

- Measurement of powdery material

In the measurement of the powder packaging machine, the stepper motor is used to control the rotation velocity and revolutions of screw. Thus, the mechanical structure is simplified and it is controlled really conveniently. Under the circumstance of no-load, the rotational velocity and stopping position of the stepper motor only depends on the frequency and pulse number of pulse signal and is free of influences of load change, which features obvious precision advantage compared to the screw measurement controlled with electromagnetic clutch. It is further applicable measuring the materials with large change in proportion. - Measurement of viscous material

Stepper motor is used to control gear pump, which also can be precisely measured. Measurement of gear pump relies on measurement of engagement rotating of a pair of gear. The material is mandatorily conveyed to the discharge hole from the feeding hole through the space among gears. Meanwhile, the power is from the stepper motor, whose location and velocity is controlled with the programmable controller. Measuring precision is higher than that of piston pump. As for viscous material packing machine, straight gear is used to increase speed. Thus, the velocity of the stepper motor is reduced; the noise is controlled; reliability is also enhanced; and the measuring precision is guaranteed.

- Reviews