- Stock: In Stock

- Model: SCJ009439

- SKU: SCJ009439

Available Options

Ask a Question About This Product

- Description

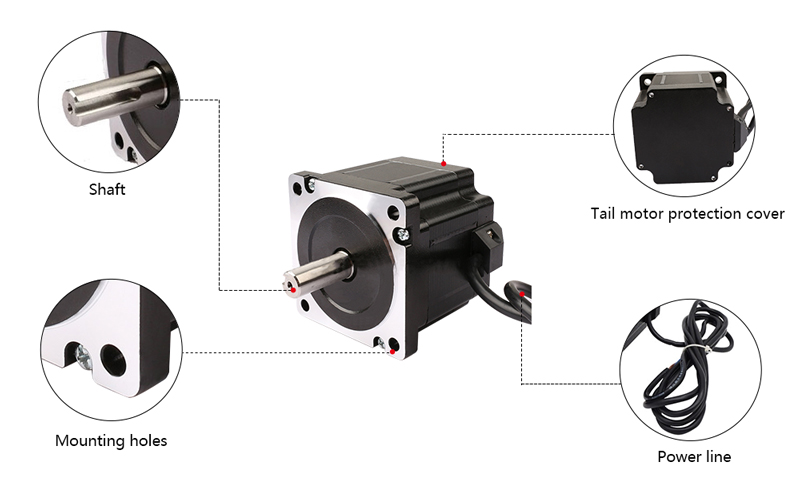

Nema 34 Stepper Motor, 4.5A, 1.8 degree, 2 phase 4 wires

Brief

Description

Nema 34 Stepper motor, 2.8Nm in 60mm, 1.8 degree.

Specification

| Basics | Model | SOCOJE260-4504A |

| Matched Driver Model | SCJ009439(Click it to see more info) | |

| Holding torque | 2.8Nm | |

| Current/phase | 4.5A | |

| Resistance | 0.5Ω | |

| Step angle | 1.8° | |

| Rotor inertia | 1000g.cm² | |

| Weight | 1.7kg | |

| Length | 60mm | |

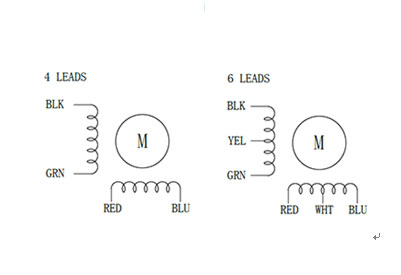

| Motor leads | 4 | |

| Technical parameters | Step Angle Accuracy | ±5%(full step, no load) |

| Resistance Accuracy | ±10% | |

| Inductance Accuracy | ±20% | |

| Temperature Rise | 80℃ Max.(rated current, 2 phase on) | |

| Ambient Temperature | -10℃~+ 50℃ | |

| Insulation Resistance | 100MΩ Min 500V DC | |

| Dielectric Strength | 500V AC for one minute | |

| Shaft Radial Play | 0.06Max.(450g) | |

| Shaft Axial Play | 0.08Max.(450g) |

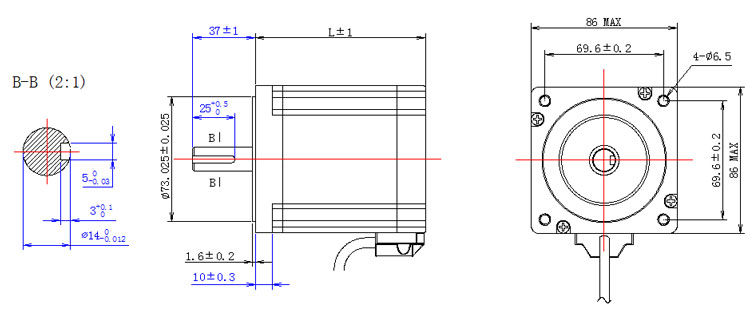

Dimensions

Motor Connection

Details

Tips: What is linear stepper motor?

“Linear stepper motor” shall be actually called “screw stepper motor” for it is not the linear motor in real sense. The rotational motion of the stepper motor can be changed into the axial to-and-fro moment through motor with screw rod. As similar to the motion of liner motor, it is called as “linear stepper motor”.

Common rotary stepper motor can run in linear motion by use of gears, synchronizing wheel, screw, rail and other mechanical structures. However, linear stepper motor can directly run in linear with simple structure and smaller size. Linear stepper motor is sensitive to load inertia; if the route is too long, air gap of linear stepper motor will be larger than that of rotary stepper motor, then causing the problems like the decrease of effective.

According to shaft mode, linear stepper motor is divided into fixed shaft, external drive and tandem shaft. Meanwhile, according to the rotor style of the stepper motor, it is divided into hybrid and PM. The most common is external drive hybrid linear stepper motor. As for the screw, there is British system and metric standard and there is single-head and multi-head screw available. External drive screw is equipped with common and anti-backlash nuts. The screw accuracy directly influences the cost of linear stepper motor to a great extent.

- Reviews